1 Name

This is the Carbon Credits (Carbon Farming—Domestic, Commercial and Industrial Wastewater) Methodology Determination Variation 2022.

2 Commencement

This instrument commences on the day after it is registered.

3 Authority

This instrument is made under section 114(1) of the Carbon Credits (Carbon Farming Initiative) Act 2011.

4 Amendment of methodology determination

The Carbon Credits (Carbon Farming Initiative—Domestic, Commercial and Industrial Wastewater) Methodology Determination 2015 is amended as set out in Schedule 1.

Schedule 1—Amendments

Carbon Credits (Carbon Farming Initiative—Domestic, Commercial and Industrial Wastewater) Methodology Determination 2015

1 Section 5

Repeal the section, substitute:

5 Definitions

In this determination

Act means the Carbon Credits (Carbon Farming Initiative) Act 2011.

anaerobic digester means a system that:

- is a covered lagoon or an engineered biodigester; and

- consists of:

- one or more closed units designed to promote anaerobic digestion; and

- a biogas collection system; and

- any equipment associated with the transfer of biogas to:

- a combustion device; or

- a biogas upgrading system.

anaerobic digestion means a biological process in which organic matter is broken down by microorganisms in the absence of oxygen.

appropriate measuring requirements, in relation to a measurement or estimate, means requirements that are consistent with:

- requirements that apply in relation to similar measurements or estimates under the NGER (Measurement) Determination; or

- relevant standards and other requirements under the National Measurement Act 1960.

biogas means a mixture of gases including methane that is generated as a result of anaerobic digestion and includes landfill gas.

biogas generation for biomethane has the meaning given by subsection 8A(2).

biogas source facility, in relation to a project, means a facility that supplies biogas to be treated as part of the project so as to produce biomethane and includes:

- a facility producing biogas for a project biomethane facility; and

- in cases where the biogas is produced at a project biomethane facility—that project biomethane facility.

Note: A biomethane facility can be its own biogas source facility if the biomethane facility also produces biogas to be treated by carrying out biomethane production.

biogas upgrading means the process by which biogas is refined and stripped of impurities to produce biomethane, which may include (but is not limited to):

- pre-treatment processing of biogas; or

- the drying or scrubbing of biogas; or

- post-treatment processing compression of the refined biomethane produced by the process.

biogas upgrading system means a system of equipment that is capable of undertaking biogas upgrading.

biogas waste means putrescible organic waste material that can be treated through anaerobic digestion to produce biogas.

biomethane means a high-methane content gas that is:

(a) produced by biogas upgrading; and

(b) suitable for use as a natural gas substitute.

biomethane conversion and displacement project has the meaning given by

section 8C.

biomethane displacement-only project has the meaning given by section 8D.

biomethane facility means a facility:

- at which biomethane production is undertaken or intended to be undertaken; and

- from which the resulting biomethane is sent, or is proposed to be sent, to an end use where it can reasonably be expected to be combusted within Australia as a natural gas substitute.

Note 1: If biogas upgrading occurs at the project treatment facility, the project treatment facility may also be a biomethane facility.

Note 2: Biomethane facilities that are used in a wastewater project that involves biogas generation for biomethane or biomethane production become known as project biomethane facilities.

Note 3: The section 22 application or section 128 application for a biomethane conversion and displacement project or a biomethane displacement-only project, and the section 22 application for a restarting biomethane conversion and displacement project or a restarting biomethane displacement-only project, must include details of at least one project biomethane facility (see paragraph 8I(2)(d)).

biomethane production has the meaning given by subsection 8A(3).

chemical oxygen demand, or COD, means the total material available for chemical oxidation (both biodegradable and non-biodegradable).

combustion device means:

- a boiler, or an internal combustion engine, that is operated in accordance with the manufacturer’s instructions; or

- a flare that has a monitoring and control system and is operated in accordance with the manufacturer’s instructions; or

- a device:

- that combusts biogas with a destruction efficiency of at least 98%; and

- that is operated in accordance with the manufacturer’s instructions; and

- the combustion process of which is controlled using a monitoring and control system.

complete, in relation to the combustion of methane or biomethane, is combustion with a destruction efficiency of 98% or more of the methane.

conversion abatement, in relation to a project, means the carbon dioxide equivalent net abatement amount for a reporting period (worked out in accordance with Division 2 of Part 4) attributable to the conversion of methane (CH4) to carbon dioxide (CO2) by carrying out:

- biogas generation for biomethane; or

- emissions destruction.

Note: Biogas generation for biomethane involves sending biogas to a biogas upgrading system to be turned into biomethane. This biogas is considered to have its methane component converted to carbon dioxide, as if it had been sent to a combustion device, because subsequent usage of the biomethane results in its combustion.

covered lagoon means a lagoon that:

- is an existing anaerobic lagoon (the uncovered lagoon) that is covered to create a closed unit; and

- does not contain any heating or stirring features that were not present in the uncovered lagoon.

deep open anaerobic lagoon means an open lagoon:

- with a depth of more than 2 metres; and

- in which the biological treatment of biomass or other organic matter occurs through anaerobic digestion; and

- from which the resulting methane emissions are not captured and are instead vented into the atmosphere.

digestate means the residual solids or semisolids stream that:

- remains in an anaerobic digester following anaerobic treatment; and

- must be removed periodically.

displacement abatement, in relation to a project, means the carbon dioxide equivalent net abatement amount for a reporting period (worked out in accordance with Division 3 of Part 4), attributable to biomethane production.

domestic or commercial wastewater has the meaning given by subsection 5.23(2) of the NGER (Measurement) Determination.

effluent, in relation to a deep open anaerobic lagoon, means the liquid outflow from the lagoon.

eligible biogas waste means biogas waste that is:

- domestic or commercial wastewater, or industrial wastewater; or

- mixed solid waste within the meaning of the Carbon Credits (Carbon Farming Initiative—Alternative Waste Treatment) Methodology Determination 2015; or

- eligible organic material within the meaning of the Carbon Credits (Carbon Farming Initiative—Source Separated Organic Waste) Methodology Determination 2016; or

- eligible animal effluent biogas waste within the meaning of the Carbon Credits (Carbon Farming Initiative—Animal Effluent Management) Methodology Determination 2019.

Note: The proportion of eligible waste used to generate biogas to be treated by carrying out biomethane production within the project must be able to be determined.

eligible wastewater, in relation to a wastewater project, means:

- domestic or commercial wastewater; or

- industrial wastewater;

from an historical source for the project.

emissions destruction has the meaning given by subsection 8A(4).

engineered biodigester means a purpose-built closed vessel that:

- is for the biological treatment of organic matter through anaerobic digestion; and

- has heating and stirring features; and

- is not a covered lagoon.

Note: Examples of engineered biodigesters include the following:

- plug flow reactors;

- continuously stirred tank reactors;

- fixed film digesters;

- up flow anaerobic sludge blanket digesters.

forerunner project:

- in relation to a restarting biomethane conversion and displacement project—has the meaning given by paragraph 8E(a); or

- in relation to a restarting biomethane displacement-only project—has the meaning given by paragraph 8F(a).

historical period of sampling means, for each deep open anaerobic lagoon that is replaced as part of a wastewater project, the period during which sampling was undertaken from the operation of that lagoon for the purposes of working out baseline emissions for the project using Subdivision 4 of Division 3 of Part 4, which:

- was 1 year or 10 consecutive days; and

- started no earlier than 18 months before the day on which a section 22 application is made in relation to the project; and

- for each deep open anaerobic lagoon that is part of the same treatment facility—is the same period of time as the historical period of sampling for each other deep open anaerobic lagoon that is part of the treatment facility.

Note 1: For a particular deep open anaerobic lagoon, the period must be the same for all sampling undertaken for the purposes of using Subdivision 4 of Division 3 of Part 4.

Note 2: Each deep open anaerobic lagoon that is part of the same treatment facility must have the same historical period of sampling.

historical source, for a wastewater project, means a source from which:

- domestic or commercial wastewater; or

- industrial wastewater;

entered a lagoon being replaced in the project during the 12 month period ending on the day before a section 22 application is made in relation to the project.

industrial wastewater has the meaning given by subsection 5.40(2) of the NGER (Measurement) Determination.

ineligible material, in relation to a wastewater project, means any organic material treated in an anaerobic digester installed as part of the project that is not eligible wastewater for the project.

influent, in relation to a deep open anaerobic lagoon, means:

- domestic or commercial wastewater; or

- industrial wastewater;

entering the lagoon.

major venting event: a major venting event occurs when biogas in the storage capacity of an anaerobic digester is released to the atmosphere in a way that does not represent the proper operation of the anaerobic digester, including:

- when the biogas is released intentionally (for example, for safety or maintenance purposes); and

- when the biogas is released unintentionally (for example, as the result of a system failure).

monitoring and control system has the meaning given by section 5A.

monitoring requirements means the requirements set out in section 45.

natural gas means a substance that:

- is in a gaseous state at standard temperature and pressure; and

- consists of naturally occurring hydrocarbons, or a naturally occurring mixture of hydrocarbons and non-hydrocarbons, the principal constituent of which is methane; and

- is suitable for consumption.

NGA Factors document means the document entitled “National Greenhouse Accounts Factors”, published by the Department and as in force from time to time.

Note: In December 2022, the NGA Factors document could be viewed on the Department’s website (http://www.industry.gov.au).

NGER (Measurement) Determination means the National Greenhouse and Energy Reporting (Measurement) Determination 2008.

non-biomethane project has the meaning given by section 8B.

non-monitored period has the meaning given by subsection 46(1).

project activity means an activity of the type listed in subsection 8A(1).

project biomethane facility, in relation to a project that involves biomethane production, means a biomethane facility that is used in carrying out the project.

Note: The section 22 application or section 128 application for a biomethane conversion and displacement project or a biomethane displacement-only project, and the section 22 application for a restarting biomethane conversion and displacement project or a restarting biomethane displacement-only project, must include details of at least one project biomethane facility (see paragraph 8I(2)(d)).

project treatment facility, in relation to a project that involves emissions destruction, or biogas generation for biomethane, means a treatment facility that is used in carrying out the project.

Note: The section 22 application or section 128 application for a biomethane conversion and displacement project or a non-biomethane project, and the section 22 application for a restarting biomethane conversion and displacement project, must include details of at least one project treatment facility (see paragraphs 8H(2)(c) and 8I(2)(c)).

project type means a project of the type listed in subsection 7(3).

restarting biomethane conversion and displacement project has the meaning given by section 8E.

restarting biomethane displacement-only project has the meaning given by section 8F.

section 22 application, in relation to an eligible offsets project, means the application under section 22 of the Act in relation to the project.

section 128 application, in relation to an eligible offsets project, means an application under section 128 of the Act to apply this determination to the project.

sludge means the solid or semisolid material that:

- accumulates at the bottom of an anaerobic lagoon; and

- is periodically cleaned out.

source, of wastewater, means the point of generation of the wastewater, which may be expressed as a physical location where the wastewater generation occurs or as a specific activity or facility that generates the wastewater.

treatment facility means a facility that treats eligible wastewater by carrying out emissions destruction, or biogas generation for biomethane, being a facility that includes:

- one or more deep open anaerobic lagoons that are replaced as part of a wastewater project; and

- one or more anaerobic digesters installed as part of the project to replace those deep open anaerobic lagoons; and

- associated equipment required to treat wastewater and capture and transport biogas generated by the installed anaerobic digesters.

Note 1: Treatment facilities that are used in a wastewater project that involves emissions destruction, or biogas generation for biomethane, become known as project treatment facilities. Division 4 of Part 3 imposes additional requirements on project treatment facilities.

Note 2: The section 22 application or section 128 application for a biomethane conversion and displacement project or a non-biomethane project, and the section 22 application for a restarting biomethane conversion and displacement project, must include details of at least one project treatment facility (see paragraphs 8G(2)(c) and 8H(2)(c)).

wastewater project has the meaning given by subsection 7(2).

2 After section 5

Insert:

5A Meaning of monitoring and control system

- A monitoring and control system for a flare or other device, is a system that consists of:

- a monitoring system that detects combustion and monitors if the combustion is operating at the manufacturer’s specifications for the complete combustion of methane; and

- an associated control system that shuts down biogas flow to the flare or other device when the flare or device is not operating at the manufacturer’s specifications for the complete combustion of methane.

Note: An example of a monitoring and control system for a flare is a flare management system that incorporates a UV detection sensor.

(2) A monitoring and control system, for a biogas upgrading system, is a system that:

- monitors the flow rate of biogas and biomethane; and

- monitors the operation and output of biogas upgrading systems; and

- is capable of automatically stopping biogas flow to the biogas upgrading system if it is not operating at the manufacturer’s specification to enable biogas upgrading.

3 Section 7

Repeal the section, substitute:

7 Wastewater projects

- For paragraph 106(1)(a) of the Act, this determination applies to an offsets project in which either or both of the following occur, in a way that can reasonably be expected to result in eligible carbon abatement:

- eligible wastewater, with or without other organic material, is treated in a treatment facility in a way that destroys methane emissions that would otherwise arise if the eligible wastewater was treated in a deep open anaerobic lagoon;

- eligible biogas produced from the treatment of eligible wastewater, with or without biogas produced from other biogas waste, is treated by biogas upgrading at a biomethane facility to produce biomethane which is then sent to an end use where it can reasonably be expected to be combusted within Australia as a natural gas substitute.

- A project covered by subsection (1) is a wastewater project.

- A wastewater project that is an eligible offsets project may be one of the following types (which are called project types in this determination):

- a non-biomethane project;

- a biomethane conversion and displacement project;

- a biomethane displacement-only project;

- a restarting biomethane conversion and displacement project;

- a restarting biomethane displacement only project.

4 Part 3

Repeal the Part, substitute:

Part 3—Project requirements

Division 1—Operation of this Part

8 Operation of this Part

- For paragraph 106(1)(b) of the Act, this Part sets out requirements that must be met for a wastewater project to be an eligible offsets project.

- Division 2 sets out project-specific requirements for each different type of wastewater project.

- Division 3 specifies the information that is required to be included in a section 22 application or section 128 application relating to a project.

- Division 4 sets out requirements for anaerobic digesters and project treatment facilities that are part of a project.

- Division 5 sets out requirements in lieu of the newness requirement for certain projects, for subparagraph 27(4A)(a)(ii) of the Act.

- Division 6 specifies the crediting period for a project, for paragraph 69(3)(b) and subparagraph 70(3)(d)(ii) of the Act.

8A Project activities

- A wastewater project must involve one or more of the following activities (which are called project activities in this determination):

- biogas generation for biomethane;

- biomethane production;

- emissions destruction.

- Biogas generation for biomethane involves:

- treating eligible wastewater by generating biogas from it; and

- capturing that biogas; and

- sending that biogas to a biogas upgrading system that is part of a project biomethane facility.

Note: Conversion abatement from biogas generation for biomethane only occurs when biomethane produced from biogas as part of the project can reasonably be expected to be combusted within Australia as a natural gas substitute.

- Biomethane production involves:

- treating biogas by biogas upgrading to produce biomethane at a project biomethane facility, with or without biogas produced from other biogas waste; and

- sending the biomethane to an end use where it can reasonably be expected to be combusted within Australia as a natural gas substitute.

Note 1: Acceptable end uses may include sale and transport to a gas retailer or gas consumer, or on-site combustion for heat or power.

Note 2: Combustion of biomethane may occur on-site at the biomethane facility, or off-site if the biomethane is transported from the biomethane facility to an end user. This may be through injection into a gas distribution or transmission network, transport via road, or another gas transport mechanism.

- Emissions destruction involves:

- treating eligible wastewater at an anaerobic digester installed at a project treatment facility in accordance with section 9 by generating biogas from it; and

- capturing the biogas; and

- combusting the biogas in a combustion device.

Division 2—Project-specific requirements

8B Requirements for non-biomethane projects

A non-biomethane project must involve the carrying out of emissions destruction.

Note: A non-biomethane project will only earn credits for the conversion abatement attributable to emissions destruction (see paragraph 12A(a)).

8C Requirements for biomethane conversion and displacement projects

A biomethane conversion and displacement project:

- must involve the installation of one or more biogas upgrading systems at a project biomethane facility; and

- must, if it involves biogas generation for biomethane, also involve biomethane production; and

- may also involve emissions destruction; and

- must not be a restarting biomethane conversion and displacement project.

8D Requirements for biomethane displacement-only projects

A biomethane displacement-only project:

- must involve the installation of one or more biogas upgrading systems at a project biomethane facility; and

- must involve biomethane production; and

- must not be a restarting biomethane displacement-only project.

Note: A biomethane displacement-only project will only earn credits for the displacement abatement attributable to biomethane production (see paragraph 12A(c)). Such a project may also involve biogas generation for biomethane, or emissions destruction, but no credits will be issued in relation to those project activities.

8E Requirements for restarting biomethane conversion and displacement projects

A restarting biomethane conversion and displacement project:

- must occur at one or more project treatment facilities that were part of an eligible offsets project (the forerunner project):

- that did not involve biogas generation for biomethane or biomethane production, or both, during its crediting period or periods; and

- for which the applicable methodology determination was the Carbon Credits (Carbon Farming Initiative—Domestic, Commercial and Industrial Wastewater) Methodology Determination 2015 or an earlier version of that determination applicable in accordance with section 125, 126, 127 or 130 of the Act; and

- the crediting period for which has expired; and

- must involve the installation of one or more biogas upgrading systems at a project biomethane facility; and

- must, if it involves biogas generation for biomethane, also involve biomethane production; and

- must have a crediting period greater than zero under section 11F.

Note: A restarting biomethane conversion and displacement project will only earn credits for the conversion abatement attributable to biogas generation for biomethane and the displacement abatement attributable to biomethane production (see paragraph 12A(d)). Such a project may also involve emissions destruction, but no credits will be issued in relation to that project activity.

8F Requirements for restarting biomethane displacement-only projects

A restarting biomethane displacement-only project must:

- occur at a biomethane facility that was part of an eligible offsets project (the forerunner project):

- that involved the carrying out of biomethane production; and

- for which the applicable methodology determination was the Carbon Credits (Carbon Farming Initiative—Domestic, Commercial and Industrial Wastewater) Methodology Determination 2015 or an earlier version of that determination applicable in accordance with section 125, 126, 127 or 130 of the Act; and

- the crediting period for which has expired; and

- involve biomethane production; and

- have a crediting period greater than zero under section 11G.

Note: A restarting biomethane displacement-only project will only earn credits for the displacement abatement attributable to biomethane production (see paragraph 12A(e)). Such a project may also involve biogas generation for biomethane, or emissions destruction, but no credits will be issued in relation to those project activities.

8G Changing project type

A project of a particular type may change to a project of a different type if it satisfies the requirements for that type immediately before the change.

Note: See Division 1 of Part 5 for the documentation of the change required in the offsets report for the project.

Division 3—Information required to be included in section 22 and 128 applications

8H Applications about non-biomethane projects

- This section applies to the section 22 application or section 128 application for a non-biomethane project.

- An application to which this section applies must include the following information:

- which project type the project will be;

- which project activities will be carried out as part of the project;

- a description of at least one project treatment facility that will be used in the project, and the following details about each project treatment facility that will be used in the project:

- a brief description of the facility;

- the location of the facility;

- the capacity of the facility, in ML or m3 of eligible wastewater treated by the facility per year;

- the deep open anaerobic lagoons that are to be replaced by anaerobic digesters that are installed as part of the project at the facility;

- evidence of the historical sources of wastewater for the project to be treated at the facility;

- the basis upon which the facility is expected to comply with the requirements of this Part and section 7;

Note: Project treatment facilities may also be adopted later, provided that they are documented in accordance with Part 5.

- a description as to how the project can reasonably be expected to result in eligible carbon abatement.

8I Applications about other projects

- This section applies to the following:

- the section 22 application or section 128 application for a biomethane conversion and displacement project or biomethane displacement-only project;

- the section 22 application for a restarting biomethane conversion and displacement project or restarting biomethane displacement-only project.

- An application to which this section applies must include the following information:

- which project type the project will be;

- which project activities will be carried out as part of the project;

- if the application relates to a biomethane conversion and displacement project or a restarting biomethane conversion and displacement project—a description of at least one project treatment facility that will be used in the project and the following details about each project treatment facility that will be used in the project:

- a brief description of the facility;

- the location of the facility;

- the capacity of the facility, in ML or m3 of eligible wastewater treated by the facility per year;

- the deep open anaerobic lagoons that are to be replaced by anaerobic digesters that are installed as part of the project at the facility;

- evidence of the historical sources of wastewater for the project to be treated at the facility;

- the basis upon which the facility is expected to comply with the requirements of this Part and section 7;

Note: Project treatment facilities may also be adopted later, provided that they are documented in accordance with Part 5.

- a description of at least one project biomethane facility that will be used in the project and the following details about each project biomethane facility that will be used in the project:

- a brief description of the facility;

- the location of the facility;

- the capacity of the facility, in m3 of biomethane produced by the facility per year;

- any known proposal for the expansion of the facility over the course of the project;

- the intended recipients of biomethane produced by the project biomethane facility;

- the basis upon which the facility is expected to comply with the requirements of this Part and section 7;

Note: Project biomethane facilities may also be adopted later, provided that they are documented in accordance with Part 5.

- a description of at least one biogas upgrading system that will be used in the project and the following details of each biogas upgrading system that will be used in the project:

- a brief description of the system;

- the location of the system;

- a declaration from the project proponent that biomethane produced by project biomethane facilities can reasonably be expected to be combusted within Australia as a natural gas substitute;

- a description as to how the project can reasonably be expected to result in eligible carbon abatement.

Division 4—Anaerobic digesters and project treatment facilities

9 Anaerobic digesters at project treatment facilities to replace lagoons

(1A) At least one anaerobic digester must be installed at each project treatment facility as part of a wastewater project to replace all deep open anaerobic lagoons at the project treatment facility.

Note: If a deep open anaerobic lagoon is not being replaced, it is not part of the project and hence not considered to be part of the project treatment facility.

- A lagoon that is to be replaced as part of a project must, before 24 April 2014:

- have existed; and

- been treating:

- domestic or commercial wastewater; or

- industrial wastewater.

- The lagoon must only treat either, or both, of the following:

- domestic or commercial wastewater;

- industrial wastewater.

10 Project treatment facilities—biogas generation for biomethane

A project treatment facility that treats eligible wastewater by biogas generation for biomethane must:

- use one or more anaerobic digesters installed as part of the project to generate and capture the biogas; and

- send that biogas to a biogas upgrading system that is part of a project biomethane facility

11 Project treatment facilities—emissions destruction

- A project treatment facility that treats eligible wastewater by emissions destruction must use:

- one or more anaerobic digesters installed as part of the project to generate and capture the biogas; and

- one or more combustion devices to destroy the proportion of the biogas that is methane.

- Each combustion device used to combust that biogas must be operated to result in the complete combustion of the proportion of the biogas that is methane.

Division 5—Newness

11A Requirement in lieu of newness requirement—restarting biomethane conversion and displacement project

- For subparagraph 27(4A)(a)(ii) of the Act, the requirement in subsection (2) is in lieu of the newness requirement for a restarting biomethane conversion and displacement project.

- The project must be a restarting biomethane conversion and displacement project.

11B Requirement in lieu of newness requirement—restarting biomethane displacement-only project

- For subparagraph 27(4A)(a)(ii) of the Act, the requirement in subsection (2) is in lieu of the newness requirement for a restarting biomethane displacement-only project.

- The project must be a restarting biomethane displacement-only project.

Division 6—Crediting period

11C Crediting period for non-biomethane projects

For paragraph 69(3)(b) and subparagraph 70(3)(d)(ii) of the Act, if a wastewater project is a non-biomethane project, the period of 7 years is specified.

11D Crediting period for biomethane conversion and displacement projects

- For paragraph 69(3)(b) and subparagraph 70(3)(d)(ii) of the Act, if a wastewater project is a biomethane conversion and displacement project that, during its crediting period or periods:

- does not treat eligible wastewater by emissions destruction; or

- does not treat eligible wastewater by emissions destruction for more than a total period of 84 calendar months;

the period of 12 years is specified.

- However, if:

- a project was a biomethane conversion and displacement project at the start of the 8th year of its crediting period; and

- before the crediting period ends under subsection (1), the total period for which eligible wastewater has been treated by emissions destruction exceeds 84 calendar months;

the crediting period ends at the start of the 85th calendar month in which emissions destruction was carried out.

- For this section and the inclusion of information in the offsets report in accordance with paragraph 42A(d):

- emissions destruction is carried out in a calendar month if at any point during 3 or more days in the calendar month eligible wastewater is treated by emissions destruction; and

- the total calendar months of emissions destruction do not need to be consecutive; and

- a calendar month after eligible wastewater is first treated by emissions destruction is presumed to be a month during which eligible wastewater is treated by emissions destruction if there is no evidence to the contrary.

- For this section, emissions destruction is not considered to have been carried out by the project during a calendar month if the project proponent chooses to exclude conversion abatement attributable to emissions destruction when working out net abatement amounts under Part 4 for that calendar month.

Note: See subparagraph 12A(b)(ii).

11E Crediting period for biomethane displacement-only projects

For paragraph 69(3)(b) and subparagraph 70(3)(d)(ii) of the Act, if a wastewater project is a biomethane displacement-only project, the period of 12 years is specified.

11F Crediting period for restarting biomethane conversion and displacement projects

For paragraph 69(3)(b) and subparagraph 70(3)(d)(ii) of the Act, if a wastewater project is a restarting biomethane conversion and displacement project, the period of 12 years minus the length of the last or only crediting period for the project’s forerunner project is specified.

Note: Section 5 defines forerunner project for a restarting biomethane conversion and displacement project as having the meaning given by paragraph 8E(a).

11G Crediting period for restarting biomethane displacement-only projects

For paragraph 69(3)(b) and subparagraph 70(3)(d)(ii) of the Act, if a wastewater project is a restarting biomethane displacement-only project, the period specified is 12 years minus the length of time between:

- the start date of the first reporting period in which the project’s forerunner project first treated biogas by biogas upgrading to produce biomethane; and

- the end date of the crediting period of that forerunner project.

Note: Section 5 defines forerunner project for a restarting biomethane conversion and displacement project as having the meaning given by paragraph 8F(a).

5 Part 4

Repeal the Part, substitute:

Part 4—Net abatement amounts

Division 1—Operation of this Part

12 Operation of this Part

- For paragraph 106(1)(c) of the Act, this Part specifies the method for working out the carbon dioxide equivalent net abatement amount for a reporting period for a wastewater project that is an eligible offsets project.

- In this Part, a reference to an anaerobic digester is a reference to an anaerobic digester that is installed as part of the project.

12A What can be included in calculating net abatement

For the purposes of working out the total carbon dioxide equivalent net abatement amount for a reporting period for a wastewater project (CO2-e):

- the calculations for a non-biomethane project must include only the conversion abatement attributable to emissions destruction, worked out using the method set out in Division 2; and

- the calculations for a biomethane conversion and displacement project must include only:

- the conversion abatement attributable to biogas generation for biomethane, worked out using the method set out in Division 2; and

- if the project also involves emissions destruction—for each calendar month in the reporting period during which the project proponent has not chosen to exclude conversion abatement attributable to emissions destruction under subsection 11D(4), the conversion abatement attributable to that emissions destruction, worked out using the method set out in Division 2; and

- the displacement abatement attributable to biomethane production, worked out using the method set out in Division 3; and

- the calculations for a biomethane displacement-only project must include only the displacement abatement attributable to biomethane production, worked out using the method set out in Division 3; and

- the calculations for a restarting biomethane conversion and displacement project must include only;

- the conversion abatement attributable to biogas generation for biomethane, worked out using the method set out in Division 2; and

- the displacement abatement attributable to biomethane production, worked out using the method set out in Division 3; and

- the calculations for a restarting biomethane displacement-only project must include only the displacement abatement attributable to biomethane production, worked out using the method set out in Division 3.

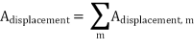

12B Working out net abatement

Subject to section 12A, the total carbon dioxide net abatement amount for a reporting period for a wastewater project, Atot, in tonnes CO2-e, is worked out using the formula (equation 1A):

where:

Aconversion, is the carbon dioxide equivalent net abatement amount attributable to the treatment of eligible wastewater by emissions destruction, or biogas generation for biomethane, at a project treatment facility for the reporting period, in tonnes CO2-e, worked out using equation 1B (section 15).

Adisplacement is the carbon dioxide equivalent net abatement amount attributable to biogas upgrading at project biomethane facilities for the reporting period, in tonnes CO2-e, worked out using equation 21 (section 41C).

Division 2 – Working out conversion abatement

Subdivision 1—Overview

13 Overview of gases accounted for in conversion abatement calculations

The following table provides an overview of the greenhouse gas abatement and emissions that are relevant to working out the carbon dioxide equivalent net abatement amount for a wastewater project that involves biogas generation for biomethane or emissions destruction.

Greenhouse gases and emissions sources |

Item | Relevant calculation | Emissions source | Greenhouse gas |

1 | Baseline emissions | Treatment of eligible wastewater for the project in deep open anaerobic lagoons at project treatment facilities | Methane (CH4) |

2 | Project emissions | Fuel consumption at project treatment facilities | Carbon dioxide (CO2) Methane (CH4) Nitrous oxide (N2O) |

3 | Project emissions | Electricity consumption at project treatment facilities | Carbon dioxide (CO2) Methane (CH4) Nitrous oxide (N2O) |

4 | Project emissions | Emissions from anaerobic digester leakage or venting events | Methane (CH4) |

5 | Project emissions | Emissions from the combustion of biogas or from the sending of biogas to a biogas upgrading system | Methane (CH4) Nitrous oxide (N2O) |

6 | Project emissions | Emissions from the end management of digestate | Methane (CH4) Nitrous oxide (N2O) |

Subdivision 2—Method for calculating net conversion abatement amount

14 Summary

The carbon dioxide equivalent net conversion abatement amount for a reporting period is worked out separately for each project treatment facility. These amounts are then added together to give the total amount for the project. The carbon dioxide equivalent net conversion abatement amount for a project treatment facility in a reporting period is worked out by calculating baseline emissions for the project treatment facility and then subtracting project emissions for the project treatment facility from that result. |

15 Net conversion abatement amount

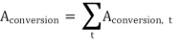

(1A) The carbon dioxide equivalent net conversion abatement amount for a reporting period, Aconversion (in tonnes CO2-e), is worked out using the formula (equation 1B):

where:

Aconversion is the carbon dioxide equivalent net conversion abatement amount for the reporting period, in tonnes CO2-e.

t is a project treatment facility.

Aconversion,t is the carbon dioxide equivalent net conversion abatement amount for project treatment facility t for the reporting period, in tonnes CO2-e, worked out using equation 1B (section 15).

- The carbon dioxide equivalent net abatement amount for the reporting period, Aconversion,t (in tonnes CO2-e) is worked out using the formula (equation 1):

where:

Aconversion,t is:

- if the carbon dioxide equivalent net conversion abatement amount for project treatment facility t for the reporting period, in tonnes CO2-e, is greater than or equal to zero—that amount; or

- if that amount is less than zero—zero.

t is a project treatment facility.

EB,t means the baseline emissions for project treatment facility t for the reporting period, in tonnes CO2-e, worked out in accordance with section 18.

EP, conversion,t means the project emissions for project treatment facility t for the reporting period, in tonnes CO2-e, worked out using equation 11 (section 32).

- If, during the reporting period, a project treatment facility:

- sends biogas to a biogas upgrading system; and

- either:

- the biogas is used for a purpose other than biogas upgrading to produce biomethane that can reasonably be expected to be combusted within Australia as a natural gas substitute; or

- the biomethane produced from biogas upgrading cannot be reasonably expected to be combusted within Australia as a natural gas substitute;

Aconversion,t is taken to be zero.

Subdivision 3—Project treatment facility baseline emissions

16 Summary

The baseline emissions for a project treatment facility for a reporting period are the emissions that would have resulted if eligible wastewater for the project treated at the project treatment facility during the reporting period in anaerobic digesters had been treated in deep open anaerobic lagoons instead. |

17 Project treatment facility baseline emissions

- The baseline emissions for a project treatment facility for a reporting period are worked out in accordance with this section.

- If sampling was undertaken from the operation of the deep open anaerobic lagoons replaced by anaerobic digesters at a project treatment facility for the purposes of working out baseline emissions for the facility, the project proponent may choose to work out baseline emissions for the project treatment facility using either Subdivision 4 or Subdivision 5.

Note: The samples will only be used if the project proponent uses Subdivision 4.

- If sampling was not undertaken from the operation of the deep open anaerobic lagoons replaced by anaerobic digesters at a project treatment facility for the purposes of working out baseline emissions for the facility, the project proponent must work out baseline emissions for the project treatment facility using Subdivision 5.

- Whichever of Subdivision 4 or Subdivision 5 is used for working out baseline emissions for a project treatment facility for the first reporting period for the project, the same Subdivision must be used for working out baseline emissions for the project treatment facility for subsequent reporting periods for the project, subject to subsection 24(2).

Note: There are consequences if certain parameters are not determined correctly: see section 24.

Subdivision 4—Calculating baseline emissions using sampling from the operation of deep open anaerobic lagoons

18 Calculating baseline emissions using sampling from deep open anaerobic lagoons

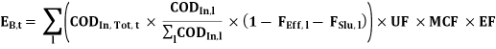

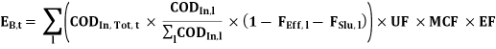

The baseline emissions for a project treatment facility for a reporting period, EB, t, in tonnes CO2-e, are worked out using the following formula (equation 2):

where:

t is a project treatment facility.

CODIn, Tot, t means the amount of chemical oxygen demand in the eligible wastewater for the project entering anaerobic digesters at project treatment facility t during the reporting period, in tonnes, worked out in accordance with the monitoring requirements.

l is a deep open anaerobic lagoon that is part of project treatment facility t and was replaced as part of the project.

CODIn, l means the amount of chemical oxygen demand in influent entering deep open anaerobic lagoon l in the historical period of sampling, in tonnes, worked out in accordance with section 21.

FEff, l means the fraction of CODIn, Tot, t that would have been removed in effluent and not undergone treatment in deep open anaerobic lagoon l to produce methane, worked out in accordance with section 19.

FSlu, l means the fraction of CODIn, Tot, t that would have been in sludge and not undergone treatment in deep open anaerobic lagoon l to produce methane, worked out in accordance with section 22.

UF means the conservativeness factor, which is 0.89.

MCF means the default methane correction factor for deep anaerobic lagoons, set out in Part 5.3 of the NGER (Measurement) Determination.

EF means the default methane emission factor for wastewater, in tonnes CO2-e per tonne COD, set out in Part 5.3 of the NGER (Measurement) Determination.

19 Fraction of chemical oxygen demand in influent removed in effluent

The fraction of CODIn, Tot, t (within the meaning of section 18) that would have been removed in effluent and not undergone treatment in deep open anaerobic lagoon l to produce methane (FEff, l), is worked out using the formula (equation 3):

where:

t is a project treatment facility.

l is a deep open anaerobic lagoon that is part of project treatment facility t and was replaced as part of the project.

CODEff, l means the amount of chemical oxygen demand in effluent leaving deep open anaerobic lagoon l in the historical period of sampling, in tonnes, worked out in accordance with section 20.

CODIn, l means the amount of chemical oxygen demand in influent entering deep open anaerobic lagoon l in the historical period of sampling, in tonnes, worked out in accordance with section 21.

AF means the adjustment factor based on the historical period of sampling that is used, which is:

- if the historical period of sampling is 1 year—1; or

- if the historical period of sampling is 10 consecutive days—1.12.

20 Chemical oxygen demand in effluent leaving a deep open anaerobic lagoon

- The amount of chemical oxygen demand in effluent leaving deep open anaerobic lagoon l in a historical period of sampling, CODEff, l, in tonnes, is worked out in accordance with this section.

- For effluent that is domestic or commercial wastewater, the amount is equivalent to parameter CODeffz calculated under Division 5.3.3 of the NGER (Measurement) Determination, with the following modifications:

- paragraphs 5.28(1)(c) and (2)(c) of that Determination are taken to be omitted;

- if the historical period of sampling is 10 consecutive days—the reference to a monthly basis in section 5.29 of that Determination is taken to be a reference to a daily basis;

- parameter CODeffz applies as if:

- a reference to “the sub facility during the reporting year” were a reference to “deep open anaerobic lagoon l for project treatment facility t in the historical period of sampling”; and

- a reference to “facility operating data” were a reference to “data about the operation of lagoon l”.

- For effluent that is industrial wastewater, the amount is equivalent to parameter CODeff calculated under Division 5.4.3 of the NGER (Measurement) Determination, with the following modifications:

- paragraphs 5.45(1)(c) and (2)(c) of that Determination are taken to be omitted;

- if the historical period of sampling is 10 consecutive days—the reference to a monthly basis in section 5.46 of that Determination is taken to be a reference to a daily basis;

- parameter CODeff applies as if a reference to “the plant during the year” were a reference to “deep open anaerobic lagoon l for project treatment facility t in the historical period of sampling”.

- In this section:

t is a project treatment facility.

l is a deep open anaerobic lagoon that is part of project treatment facility t and was replaced as part of the project.

21 Chemical oxygen demand in influent entering a deep open anaerobic lagoon

- The amount of chemical oxygen demand in influent entering deep open anaerobic lagoon l in a historical period of sampling, CODIn, l (in tonnes), is worked out in accordance with this section.

- For influent that is domestic or commercial wastewater, the amount is equivalent to parameter CODwz calculated under Division 5.3.3 of the NGER (Measurement) Determination, with the following modifications:

- paragraphs 5.28(1)(c) and (2)(c) of that Determination are taken to be omitted;

- if the historical period of sampling is 10 consecutive days—the reference to a monthly basis in section 5.29 of that Determination is taken to be a reference to a daily basis;

- parameter CODwz applies as if:

- a reference to “the sub facility during the year” were a reference to “deep open anaerobic lagoon l for project treatment facility t in the historical period of sampling”; and

- a reference to “facility operating data” were a reference to “data about the operation of lagoon l”.

- For influent that is industrial wastewater, the amount is equivalent to parameter CODw,i calculated under Division 5.4.3 of the NGER (Measurement) Determination, with the following modifications:

- paragraphs 5.45(1)(c) and (2)(c) of that Determination are taken to be omitted;

- if the historical period of sampling is 10 consecutive days—the reference to a monthly basis in section 5.46 of that Determination is taken to be a reference to a daily basis;

- parameter CODw,i (as described in subsection 5.43(2) of the NGER (Measurement) Determination) applies as if:

- a reference to “the plant” were a reference to “deep open anaerobic lagoon l for project treatment facility t in the historical period of sampling”; and

- a reference to “facility operating data” were a reference to “data about the operation of lagoon l”.

- In this section:

t is a project treatment facility.

l is a deep open anaerobic lagoon that is part of project treatment facility t and was replaced as part of the project.

22 Fraction of chemical oxygen demand in influent that would be in sludge

- The fraction of CODIn, Tot, t (within the meaning of section 18) that would have been in sludge and not undergone treatment in deep open anaerobic lagoon l to produce methane (FSlu, l), is worked out as follows:

- if the historical period of sampling is 10 consecutive days—using the default value mentioned in subsection (2);

- if the historical period of sampling is 1 year—using either of the following, as chosen by the project proponent:

- the default value mentioned in subsection (2); or

- equation 4.

- The default value is:

- for domestic or commercial wastewater only—0.6; or

- for industrial wastewater only—0.17; or

- for a mixture of domestic or commercial wastewater and industrial wastewater—0.6.

- The following formula is equation 4:

where:

t is a project treatment facility.

l is a deep open anaerobic lagoon that is part of project treatment facility t and was replaced as part of the project.

FSlu, l means the fraction of CODIn,t that would have been in sludge and not undergone treatment in deep open anaerobic lagoon l to produce methane.

CODSlu, l means the amount of chemical oxygen demand in sludge in deep open anaerobic lagoon l in the historical period of sampling (which is 1 year), in tonnes, worked out in accordance with section 23.

CODIn, l means the amount of chemical oxygen demand in influent entering deep open anaerobic lagoon l in the historical period of sampling (which is 1 year), in tonnes, worked out in accordance with section 21.

- In this section:

l is a deep open anaerobic lagoon that is part of project treatment facility t and was replaced as part of the project.

23 Chemical oxygen demand in sludge in a deep open anaerobic lagoon

- The amount of chemical oxygen demand in sludge in deep open anaerobic lagoon l in the historical period of sampling (which is 1 year), CODSlu, l (in tonnes), is worked out in accordance with this section.

- For sludge produced from the treatment of domestic or commercial wastewater, the amount is equivalent to parameter CODslz calculated under Division 5.3.3 of the NGER (Measurement) Determination, with the following modifications:

- paragraphs 5.28(1)(c) and (2)(c) of that Determination are taken to be omitted;

- parameter CODslz applies as if a reference to the quantity of COD removed as sludge (however described) from wastewater and treated in a sub facility were a reference to the quantity of COD in sludge produced in deep open anaerobic lagoon l for project treatment facility t in the historical period of sampling.

- For sludge produced from the treatment of industrial wastewater, the amount is equivalent to parameter CODsl calculated under Division 5.4.3 of the NGER (Measurement) Determination, with the following modifications:

- paragraphs 5.45(1)(c) and (2)(c) of that Determination are taken to be omitted;

- parameter CODsl applies as if:

- a reference to the quantity of COD removed as sludge from wastewater during a year were a reference to the quantity of COD in sludge produced in deep open anaerobic lagoon l for project treatment facility t in the historical period of sampling; and

- parameter CODw,i (as described in subsection 5.43(2) of the NGER (Measurement) Determination) applies in the same way as described in subsection 21(3).

- In this section:

t is a project treatment facility.

l is a deep open anaerobic lagoon that is part of project treatment facility t and was replaced as part of the project.

24 Consequences if certain parameters are not determined correctly

- If parameter FSlu, l is not determined correctly using equation 4 (section 22), the fraction of CODIn, l (within the meaning of section 18) that would, in a deep open anaerobic lagoon, have been in sludge and not undergone treatment in the lagoon to produce methane, must be worked out using the default value mentioned in subsection 22(2).

- If parameter FEff, l is not determined correctly using equation 3 (section 19):

- baseline emissions for a reporting period must be worked out using Subdivision 5; or

- the carbon dioxide equivalent net conversion abatement amount for project treatment facility t for the reporting period is taken to be zero.

Note: If, under paragraph (2)(a), baseline emissions for a reporting period are worked out under Subdivision 5, Subdivision 5 must also be used for working out baseline emissions for subsequent reporting periods for the project: see subsection 17(4).

- In this section:

t is a project treatment facility.

Subdivision 5—Calculating baseline emissions using the amount of methane sent to a combustion device or biogas upgrading system

25 Calculating baseline emissions using methane sent to a combustion device or biogas upgrading system

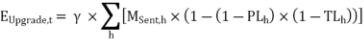

The baseline emissions for project treatment facility t for a reporting period are worked out using the following formula (equation 5):

where:

EB,t means the baseline emissions for project treatment facility t for the reporting period, in tonnes CO2-e.

t is a project treatment facility.

means the factor, set out in Part 5.3 of the NGER (Measurement) Determination, that converts cubic metres of methane to tonnes CO2-e at standard conditions.

Note: In 2022, γ was 6.784 x 10-4 x 28.

WEW,t means the proportion of methane generated at project treatment facility t that is generated by eligible wastewater for the project during the reporting period, worked out in accordance with section 26.

h means:

- a combustion device used at project treatment facility t; or

- a biogas upgrading system of a project biomethane facility.

MSent t,h means the methane from project treatment facility t sent to combustion device or biogas upgrading system h during the reporting period, in cubic metres, worked out in accordance with section 30.

WDAL means the proportion of methane that is generated in anaerobic digesters that would have been generated in deep open anaerobic lagoons that are part of project treatment facility t and were replaced as part of the project, which is:

- if no anaerobic digesters installed at project treatment facility t as part of the project are engineered biodigesters—1; or

- otherwise—0.75.

26 Proportion of methane that is generated by eligible wastewater

- The proportion of methane generated at project treatment facility t that is generated by eligible wastewater for the project during a reporting period (WEW,t) is:

- if both of the conditions in subsection (2) are satisfied for the reporting period—1;

- if one or both of the conditions in subsection (2) are not satisfied for the reporting period—worked out using equation 6.

- The conditions are as follows:

- the volume of an individual type of ineligible material for the project treated in anaerobic digesters at project treatment facility t during the reporting period (QMat,w,t) does not exceed 0.5% of the total volume of material treated in anaerobic digesters at project treatment facility t during the reporting period (QMat,t);

- the volume of all ineligible material for the project treated in anaerobic digesters at project treatment facility t during the reporting period (ƩwQMat,w,t) is less than 2% of the total volume of material treated in anaerobic digesters at project treatment facility t during the reporting period (QMat,t);

where QMat,w,t and QMat,t are worked out in accordance with the monitoring requirements and w is a type of ineligible material for the project treated in anaerobic digesters at project treatment facility t during the reporting period.

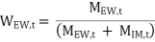

- The following formula is equation 6:

where:

t is a project treatment facility.

WEW,t means the proportion of methane generated at project treatment facility t that is generated by eligible wastewater for the project during the reporting period.

MEW,t means methane generated by eligible wastewater at project treatment facility t for the project during the reporting period, in cubic metres, worked out using equation 7 (section 27).

MIM,t means methane generated by ineligible material at project treatment facility t for the project during the reporting period, in cubic metres, worked out using equation 8 (section 28).

27 Methane generated by eligible wastewater

The methane generated by eligible wastewater for the project at project treatment facility t during a reporting period MEW,t , in cubic metres, is worked out using the formula (equation 7):

where:

t is a project treatment facility.

MEW,t means the methane generated by eligible wastewater for the project at project treatment facility t during the reporting period, in cubic metres.

w means a type of eligible wastewater for the project treated in anaerobic digesters at project treatment facility t during the reporting period.

VSw,t means the amount of volatile solids from material type w treated in anaerobic digesters at project treatment facility t during the reporting period, in kilograms, worked out in accordance with the monitoring requirements.

MMax,w means the maximum methane producing capacity of material type w, in cubic metres of methane per kilogram of volatile solids, worked out in accordance with section 29.

28 Methane generated by ineligible material

The methane generated by ineligible material for the project at project treatment facility t during a reporting period, MIM,t (in cubic metres), is worked out using the formula (equation 8):

where:

t is a project treatment facility.

MIM,t means the methane generated by ineligible material for the project at project treatment facility t during the reporting period, in cubic metres.

w means a type of ineligible material for the project treated in anaerobic digesters at project treatment facility t during the reporting period.

VSw,t means the amount of volatile solids from material type w treated in anaerobic digesters at project treatment facility t during the reporting period, in kilograms, worked out in accordance with the monitoring requirements.

MMax,w means the maximum methane producing capacity of material type w, in cubic metres of methane per kilogram of volatile solids, worked out in accordance with section 29.

29 Maximum methane producing capacities

- The maximum methane producing capacity of material type w (which could be eligible wastewater for the project or ineligible material for the project), MMax,w, is worked out in accordance with this section.

- If the table in clause 1 of Schedule 1 sets out a default value for material type w, MMax,w may be worked out:

- by using the default value in the table in clause 1 of Schedule 1 for material type w; or

- using the monitoring requirements.

Note: Different options (that is, using the default value or using the monitoring requirements) may be used for different material types.

- If the table in clause 1 of Schedule 1 does not set out a default value for material type w, MMax,w must be worked out in accordance with the monitoring requirements.

- If, at any time during the project;

- the table in clause 1 of Schedule 1 is amended so that it sets out a default value for material type w; and

- before the amendment there was no default value set out in the table for material type w;

MMax,w may be worked out, following the amendment, by using the default value.

- However, if, at any time during the project:

- the table in clause 1 of Schedule 1 sets out a default value for material type w; and

- MMax,w is worked out in accordance with the monitoring requirements;

MMax,w must be worked out in accordance with the monitoring requirements for the remainder of the project.

30 Methane sent to combustion device or biogas upgrading system

- The methane from project treatment facility t sent during a reporting period to combustion device or biogas upgrading system h, MSent t, h (in cubic metres), is worked out as follows:

- in the case of a combustion device that is an internal combustion engine—using equation 9 or 10;

- in the case of a biogas upgrading system—using equation 9 or, subject to subsection (2B), equation 9A;

- in any other case—using equation 9.

- The following formula is equation 9:

where:

MSent t,h means the methane from project treatment facility t sent to combustion device or biogas upgrading system h during the reporting period, in cubic metres.

QBG t,h means the biogas from project treatment facility t sent to combustion device or biogas upgrading system h during the reporting period, in cubic metres, worked out in accordance with the monitoring requirements.

WBG, CH4, t, h means the proportion of the volume of the biogas from project treatment facility t sent to combustion device or biogas upgrading system h that is methane, worked out in accordance with the monitoring requirements.

(2A) The following formula is equation 9A:

where:

MSent t,h means the methane from project treatment facility t sent to biogas upgrading system h during the reporting period, in cubic metres.

QBM, h is the total volume of biomethane sent out by biogas upgrading system h during the reporting period, in cubic metres, determined in accordance with the monitoring requirements.

WBM, CH4, h is the proportion of QBM, h that is methane, expressed as a fraction, determined in accordance with the monitoring requirements.

(2B) For subsection (1), equation 9A cannot be used to determine MSent t,h if, in a reporting period, biogas upgrading system h receives biogas from:

- more than one project treatment facility; or

- a biogas source facility that is not part of the project.

Note: MSent t,h is worked out for each combustion device or biogas upgrading system used at project treatment facility t. If a biogas upgrading system receives biogas from more than one source, equation 9A cannot be used since apportioning the proportion of methane in the produced biomethane attributable to biogas from a specific project treatment facility is not feasible – equation 9 would be more appropriate in that circumstance.

- The following formula is equation 10:

where:

MSent t,h means the methane from project treatment facility t sent to combustion device h during the reporting period, in cubic metres.

QEG,h means the electricity (supplied to the electricity grid or used on site) produced by combustion device h during the reporting period, in megawatt hours, worked out in accordance with the monitoring requirements.

FMWh→GJ means the factor to convert megawatt hours to gigajoules, which is 3.6.

EEh means:

- the factor for the electrical efficiency of combustion device h, determined in accordance with:

- the manufacturer’s specifications for the combustion of biogas; and

- if the specifications set out a range of such efficiencies—the highest of those efficiencies; or

- if the factor mentioned in paragraph (a) cannot be determined in accordance with the manufacturer’s specifications—the amount set out in subsection 2.38(2) of the NGER (Measurement) Determination.

ECBG means the energy content factor for sludge biogas that is captured for combustion (methane only), in gigajoules per cubic metre, set out in Part 2 of Schedule 1 to the NGER (Measurement) Determination.

Subdivision 6—Project treatment facility project emissions

31 Summary

The project emissions for a project treatment facility for a reporting period are the emissions that result from operating the project treatment facility during the reporting period. Emissions from fuel and electricity use, anaerobic digester leakage and venting events, combustion of biogas or the sending of biogas to a biogas upgrading system, and digestate treatment are added together to determine the total project emissions. |

32 Project treatment facility project emissions

- The project emissions for project treatment facility t for a reporting period, EP, conversion, t (in in tonnes CO2-e) is worked out using the formula (equation 11):

where:

t is a project treatment facility.

EP, conversion, t means the project emissions for project treatment facility t for the reporting period, in tonnes CO2-e.

EF, conversion, t means the emissions from fuel used at project treatment facility t during the reporting period, in tonnes CO2-e, worked out using equation 12.

EEP, conversion, t means the emissions from purchased electricity used at project treatment facility t during the reporting period, in tonnes CO2-e, worked out using equation 13 (section 34).

EAD, t means the emissions from anaerobic digester leakage or venting events at project treatment facility t during the reporting period, in tonnes CO2-e, worked out in accordance with section 35.

ECom, t means the methane combustion emissions from methane destroyed by combustion devices or taken to have been destroyed by biogas upgrading systems for project treatment facility t during the reporting period, in tonnes CO2-e, worked out in accordance with section 37.

EUpgrade, t means the production and transport emissions from methane sent to biogas upgrading systems at project treatment facility t during the reporting period, in tonnes CO2-e, worked out in accordance with section 37B.

EDig, t means the emissions from the end management of the digestate treated at project treatment facility t during the reporting period, in tonnes CO2-e, worked out using equation 17 (section 38).

- In determining EF, conversion, t and EPE, conversion, t, emissions associated with biogas upgrading should be disregarded, including emissions from the operation of biogas upgrading systems and any downstream transport emissions during the reporting period, in tonnes CO2-e, worked out using equation 26 (section 41L).

Note: This ensures that double counting of project emissions does not occur. Project emissions from fuel and electricity used in biogas upgrading systems is accounted for when working out net displacement abatement in Division 3 of this Part.

33 Emissions from fuel use: conversion abatement

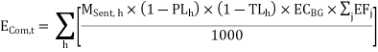

The emissions from fuel used at a project treatment facility during a reporting period, EF, conversion, t (in in tonnes CO2-e), is worked out using the formula (equation 12):

where:

EF, conversion, t means the emissions from fuel used at project treatment facility t during the reporting period, in tonnes CO2-e.

t is a project treatment facility.

i means a fuel type.

j means a greenhouse gas type.

QF,i,t means the amount of fuel type i used that is specifically attributable to emissions destruction or biogas generation during the reporting period, in tonnes, kilolitres, cubic metres, or gigajoules, worked out in accordance with the monitoring requirements.

ECi means the energy content factor for fuel type i in gigajoules per tonne, gigajoules per kilolitre or gigajoules per cubic metre, set out in Part 1, 2 or 3 of Schedule 1 to the NGER (Measurement) Determination.

Note: If QF,i,t is measured in gigajoules, then ECi is not required (ECi=1).

EFij means the emission factor, in kilograms CO2-e per gigajoule, set out in Part 1, 2 or 3 of Schedule 1 to the NGER (Measurement) Determination for greenhouse gas type j and fuel type i.

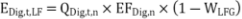

34 Emissions from purchased electricity use: conversion abatement

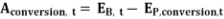

- The emissions from purchased electricity used at project treatment facility t during a reporting period, EEP, conversion, t (in tonnes CO2-e) is worked out using the formula (equation 13):

where:

t is a project treatment facility.

EEP, conversion t means the emissions from purchased electricity used at project treatment facility t during the reporting period, in tonnes CO2-e.

QEP,t means the amount of purchased electricity used at project treatment facility t during the reporting period, in kilowatt hours, worked out in accordance with the monitoring requirements.

EFEP means:

- for electricity obtained from an electricity grid that is a grid in relation to which the NGA Factor document includes an emissions factor—that factor, in kilograms CO2-e per kilowatt hour; or

- for electricity obtained from an electricity grid not covered by paragraph (a) or from a source other than an electricity grid:

- if the supplier of the electricity is able to provide an emissions factor that reflects the emissions intensity of the electricity—that factor, in kilograms CO2-e per kilowatt hour; or

- otherwise—the emissions factor, in kilograms CO2-e per kilowatt hour, for off-grid electricity included in the NGA Factors document.

- For subparagraph (b)(i) of the definition of EFEP in subsection (1), the emissions factor must be worked out:

- on a sent-out basis; and

- using a measurement or estimation approach that is consistent with the NGER (Measurement) Determination.

35 Emissions from anaerobic digester leakage or venting events

- The emissions from anaerobic digester leakage or venting events at project treatment facility t during a reporting period are worked out:

- if Subdivision 4 of Division 2 is used to work out baseline emissions for the project treatment facility for the reporting period—using equation 14; or

- if Subdivision 5 of Division 2 is used to work out baseline emissions for the project treatment facility for the reporting period—as follows:

- if the volume of all ineligible material treated in anaerobic digesters at the project treatment facility during the reporting period (ƩwQMat,w,t) is less than 10% of the total volume of material treated in anaerobic digesters during the reporting period (QMat,t), where QMat,w,t and QMat,t are worked out in accordance with the monitoring requirements and w is a type of ineligible material for the project treated in anaerobic digesters at the project treatment facility during the reporting period—the emissions have a default value of zero;

- otherwise—worked out using equation 14.

- The emissions from anaerobic digester leakage or venting events at project treatment facility t during the reporting period, EAD,t (in tonnes CO2-e) is worked out using the formula (equation 14):

where:

t is a project treatment facility.

EAD,t means the emissions from anaerobic digester leakage or venting events at project treatment facility t during the reporting period, in tonnes CO2-e.

γ means the factor, set out in Part 5.3 of the NGER (Measurement) Determination, that converts cubic metres of methane to tonnes CO2-e at standard conditions.

Note: In 2022, γ was 6.784 x 10-4 x 28.

CF means the correction factor to reflect the proportion of EAD,t that is not accounted for in the calculation of baseline emissions, which is:

- if Subdivision 4 of Division 2 is used to work out baseline emissions for project treatment facility t for the reporting period—1; and

- if Subdivision 5 of Division 2 is used to work out baseline emissions for project treatment facility t for the reporting period—1 minus WEW,t.

CE means the biogas collection efficiency of an anaerobic digester, (that is, the percentage of biogas generated in an anaerobic digester that is sent to a combustion device), which is 0.98.

h means:

- a combustion device used at project treatment facility t; or

- a biogas upgrading system of a project biomethane facility.

MSent t,h means the methane from project treatment facility t sent to combustion device or biogas upgrading system h during the reporting period, in cubic metres, worked out in accordance with section 30.

q means a major venting event associated with an anaerobic digester at project treatment facility t during the reporting period.

MVent,q means the volume of methane vented due to major venting event q during the reporting period, in cubic metres, worked out using equation 15 (section 36).

WEW,t means the proportion of methane generated at project treatment facility t that is generated by eligible wastewater for the project during the reporting period, worked out in accordance with section 26.

36 Volume of methane vented due to a major venting event

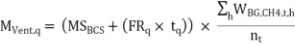

If a major venting event associated with an anaerobic digester that is part of project treatment facility t occurs during a reporting period, the volume of methane vented due to the major venting event, MVent,q (in cubic metres), is worked out using the formula (equation 15):

where:

q means a major venting event associated with an anaerobic digester at project treatment facility t during the reporting period.

MVent,q means the volume of methane vented due to major venting event q, in cubic metres.

MSBCS means the maximum biogas storage capacity, of the anaerobic digester, in cubic metres, worked out in accordance with the monitoring requirements.

FRq means the average total daily flow of biogas, from the anaerobic digester for the 7 days before major venting event q, in cubic metres per day, worked out in accordance with the monitoring requirements.

tq means the number of days for all or part of which major venting event q is uncontrolled, worked out in accordance with the monitoring requirements.

WBG, CH4 ,t, h means the proportion of the volume of the biogas from project treatment facility t sent to combustion device or biogas upgrading system h that is methane, worked out in accordance with the monitoring requirements.

nt means the number of combustion devices or biogas upgrading systems h that receive biogas from project treatment facility t during the reporting period.

Note: The final term in equation 15 calculates the average proportion of the volume of the biogas sent from project treatment facility t that is methane during a reporting period.

37 Emissions from combustion of biogas

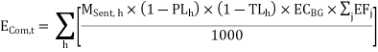

For the purposes of section 32, the methane combustion emissions from methane destroyed by combustion devices or taken to have been destroyed by biogas upgrading systems for project treatment facility t during a reporting period, ECom,t (in tonnes CO2-e), is worked out using the formula (equation 16):

where:

t is a project treatment facility.

ECom,t means the methane combustion emissions from methane destroyed by combustion devices or taken to have been destroyed by biogas upgrading systems for project treatment facility t during the reporting period, in tonnes CO2-e.

h means:

- a combustion device used at project treatment facility t; or

- a biogas upgrading system of a project biomethane facility.

MSent t, h means the methane from project treatment facility t sent to combustion device or biogas upgrading system h during the reporting period, in cubic metres, worked out in accordance with section 30.