TABLE OF CONTENTS

FOREWORD 5

- INTRODUCTION 6

- Who has health and safety duties in relation to noise? 6

- The meaning of key terms 6

- What is required to manage the risks of hearing loss? 7

- NOISE AND ITS EFFECT ON HEALTH AND SAFETY 9

- How does hearing loss occur? 9

- How much noise is too much? 9

- Other effects of noise 10

- HOW TO identify the hazards 12

3.1 How to find noise hazards 12

3.2 What happens next? 13

4. HOW TO ASSESS THE RISKS 14

4.1 When should a risk assessment be conducted? 14

4.2 Who can do a noise assessment? 14

4.3 How should a noise assessment be done? 14

4.4. What information should be included in a noise assessment report? 15

5. HOW TO CONTROL THE RISKS 16

5.1 The hierarchy of risk control 16

5.2 Substituting plant or processes to reduce noise 16

5.3 Using engineering controls 17

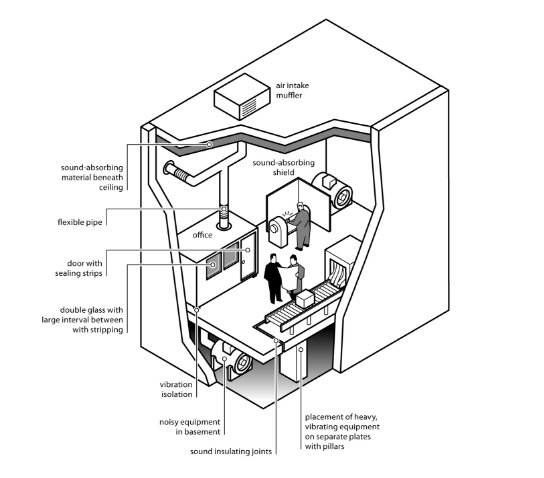

5.4 Isolating the source of noise 17

5.5 Using administrative controls 18

5.6 Using personal hearing protectors 19

5.7 Audiometric testing 21

5.8 Information, training and instruction 22

5.9 Implementing and maintaining control measures 22

6. HOW TO REVIEW CONTROL MEASURES 24

7. ROLE OF DESIGNERS, MANUFACTURERS, SUPPLIERS AND

INSTALLERS 25

7.1 Designers 25

7.2 Manufacturers 27

7.3 Suppliers and importers 28

7.4 Installers 28

7.5 What information should be provided to potential users? 28

Appendix A – other Causes OF Hearing Loss in the workplace 30

APPENDIX B – NOISE HAZARD IDENTIFICATION CHECKLIST 35

APPENDIX C – READY RECKONER 36

Appendix D – Contents of a noise assessment report 41

Appendix E – engineering CONTROL MEASURES 42

This Code of Practice for managing noise and preventing hearing loss at work is an approved code of practice under section 274 of the Work Health and Safety Act (the WHS Act).

An approved code of practice is a practical guide to achieving the standards of health, safety and welfare required under the WHS Act and the Work Health and Safety Regulations (the WHS Regulations).

A code of practice applies to anyone who has a duty of care in the circumstances described in the code. In most cases, following an approved code of practice would achieve compliance with the health and safety duties in the WHS Act, in relation to the subject matter of the code. Like regulations, codes of practice deal with particular issues and do not cover all hazards or risks that may arise. The health and safety duties require duty holders to consider all risks associated with work, not only those for which regulations and codes of practice exist.

Codes of practice are admissible in court proceedings under the WHS Act and Regulations. Courts may regard a code of practice as evidence of what is known about a hazard, risk or control and may rely on the code in determining what is reasonably practicable in the circumstances to which the code relates.

Compliance with the WHS Act and Regulations may be achieved by following another method, such as a technical or an industry standard, if it provides an equivalent or higher standard of work health and safety than the code.

An inspector may refer to an approved code of practice when issuing an improvement or prohibition notice.

This Code of Practice has been developed by Safe Work Australia as a model code of practice under the Council of Australian Governments’ Inter-Governmental Agreement for Regulatory and Operational Reform in Occupational Health and Safety for adoption by the Commonwealth, state and territory governments.

A draft of this Code of Practice was released for public consultation on 7 December 2010 and was endorsed by the Workplace Relations Ministers’ Council on 10 August 2011.

This Code of Practice applies to all types of work and all workplaces covered by the WHS Act where there is the potential for exposure to noise that can contribute to hearing loss. It provides practical guidance to persons conducting a business or undertaking on how noise affects hearing, how to identify and assess exposure to noise and how to control health and safety risks arising from hazardous noise.

Although the WHS Regulations for noise are limited to managing the risks of hearing loss, the duties in the WHS Act extend to all health and safety risks arising from the conduct of a business or undertaking and therefore this Code also includes information about other agents that may contribute to hearing loss in Appendix A.

In providing guidance, the word ‘should’ is used in this Code to indicate a recommended course of action, while ‘may’ is used to indicate an optional course of action.

This Code also includes various references to sections of the WHS Act and Regulations which set out the legal requirements. These references are not exhaustive. The words ‘must’, ‘requires’ or ‘mandatory’ indicate that a legal requirement exists and must be complied with.

Hazardous noise can destroy the ability to hear clearly and can also make it more difficult to hear sounds necessary for working safely, such as instructions or warning signals.

Managing the risks related to noise will assist in:

- protecting workers from hearing loss and disabling tinnitus (ringing in the ears or head)

- improving the conditions for communication and hearing warning sounds

- creating a less stressful and more productive work environment.

A person conducting a business or undertaking has the primary duty under the WHS Act to ensure, so far as is reasonably practicable, that workers and other persons are not exposed to health and safety risks arising from the business or undertaking.

A person conducting a business or undertaking has more specific obligations under the WHS Regulations to manage the risks of hearing loss associated with noise at the workplace, including:

- ensuring that the noise a worker is exposed to at the workplace does not exceed the exposure standard for noise

- providing audiometric testing to a worker who is frequently required to use personal hearing protectors to protect the worker from hearing loss associated with noise that exceeds the exposure standard.

Designers, manufacturers, suppliers, importers and installers of plant or structures that could be used for work must ensure, so far as is reasonably practicable, that the plant or structure is without risks to health and safety. Designers and manufacturers of plant must ensure the plant is designed and manufactured so that its noise emission is as low as reasonably practicable.

Designers, manufacturers, suppliers and importers must also provide information about the noise emission values of the plant and any conditions necessary for minimising the risk of hearing loss and other harm (see Chapter 7 of this Code).

Officers, such as company directors, have a duty to exercise due diligence to ensure that the business or undertaking complies with the WHS Act and Regulations. This includes taking reasonable steps to ensure that the business or undertaking has and uses appropriate resources and processes to eliminate or minimise risks that arise from noise.

Workers have a duty to take reasonable care for their own health and safety and that they do not adversely affect the health and safety of other persons. Workers must comply with any reasonable instruction and cooperate with any reasonable policy or procedure relating to health and safety at the workplace. For example, if personal hearing protectors are provided by the person conducting the business or undertaking, the worker must use them in accordance with the information, instruction and training provided on their use.

Decibel (dB) is the unit for measuring sound levels.

Exposure standard for noise is defined in the WHS Regulations as an LAeq,8h of 85 dB(A) or an LC,peak of 140 dB(C). There are two parts to the exposure standard for noise because noise can either cause gradual hearing loss over a period of time or be so loud that it causes immediate hearing loss.

LAeq,8h means the eight hour equivalent continuous A-weighted sound pressure level in decibels, referenced to 20 micropascals, determined in accordance with AS/NZS 1269.1. This is related to the total amount of noise energy a person is exposed to in the course of their working day. It takes account of both the noise level and the length of time the person is exposed to it. An unacceptable risk of hearing loss occurs at LAeq,8h values above 85 dB(A).

LC,peak means the C-weighted peak sound pressure level in decibels, referenced to 20 micropascals, determined in accordance with AS/NZS 1269.1. It usually relates to loud, sudden noises such as a gunshot or hammering. LC,peak values above 140 dB(C) can cause immediate damage to hearing.

Hazardous noise in relation to hearing loss means noise that exceeds the exposure standard for noise in the workplace.

Risk control means taking action to first eliminate health and safety risks so far as is reasonably practicable, and if that is not possible, minimising the risks so far as is reasonably practicable. Eliminating a hazard will also eliminate any risks associated with that hazard.

Regulation 34-38: In order to manage risk under the WHS Regulations, a duty holder must:

a) identify reasonably foreseeable hazards that could give rise to the risk

b) eliminate the risk so far as is reasonably practicable

c) if it is not reasonably practicable to eliminate the risk – minimise the risk so far as is reasonably practicable by implementing control measures in accordance with the hierarchy of control

d) maintain the implemented control measure so that it remains effective

d) review, and if necessary revise, risk control measures so as to maintain, so far as is reasonably practicable, a work environment that is without risks to health and safety.

This Code provides guidance on how to manage the risks of hearing loss associated with noise by following a systematic process that involves:

- identifying sources of noise that may cause or contribute to hearing loss,

- if necessary, assessing the risks associated with these hazards,

- implementing risk control measures

- reviewing risk control measures.

Guidance on the general risk management process is available in the Code of Practice: How to Manage Work Health and Safety Risks.

Consultation involves sharing of information, giving workers a reasonable opportunity to express views and taking those views into account before making decisions on health and safety matters.

Section 47: The WHS Act requires that you consult, so far as is reasonably practicable, with workers who carry out work for you who are (or are likely to be) directly affected by a work health and safety matter.

Section 48: If the workers are represented by a health and safety representative, the consultation must involve that representative.

Consultation with workers and their health and safety representatives is required at each step of the risk management process. By drawing on the experience, knowledge and ideas of your workers you are more likely to identify all hazards and choose effective control measures.

You must also consult your workers when proposing to make any changes that may affect their health and safety, for example when planning to buy new machinery or equipment.

Health and safety representatives must have access to relevant information such as noise exposure data and potential control options. If you have a health and safety committee, you should engage the committee in the process as well.

Section 46: The WHS Act requires that you consult, co-operate and co-ordinate activities with all other persons who have a work health or safety duty in relation to the same matter, so far as is reasonably practicable.

Sometimes you may share responsibility for a health and safety matter with other business operators who are involved in the same activities or who share the same workplace. In these situations, you should exchange information to find out who is doing what and work together in a co-operative and co-ordinated way so that all risks are eliminated or minimised as far as reasonably practicable.

For example, if you own or manage an on-hire business and your workers work at other workplaces then you must consult the host business so far as is reasonably practicable to determine if your workers could be exposed to hazardous noise and agree on what you each will do to control any associated risks.

Further guidance is available in the Code of Practice: Work Health and Safety Consultation, Co-operation and Co-ordination.

Hazardous noise affects the functioning of the inner ear, which may cause temporary hearing loss. After a period of time away from noise, hearing may be restored. With further exposure to hazardous noise, the ear will gradually lose its ability to recover and the hearing loss will become permanent.

Permanent hearing loss can also occur suddenly if a person is exposed to very loud impact or explosive sounds. This type of damage is known as acoustic trauma.

Permanent hearing loss results from the destruction of hair cells in the inner ear. These cells cannot be replaced or repaired by any presently known medical treatments or technology.

Usually, hazardous noise first affects the ability to hear high-frequency (high-pitched) sounds. This means that even though a person can still hear some sounds, conversation will start to sound ‘muffled’ and a person may find it difficult to understand what is being said.

Communication difficulties occur especially when there are competing background noises. Modern hearing aids may improve the ability to hear speech but they are unable to completely restore the clarity of the full hearing function.

Workers exposed to hazardous noise may also experience tinnitus, which could become permanent. When severe, it may disrupt sleep, reduce concentration, make people extremely irritable and lead to depression.

The degree of hearing loss that occurs is dependent on how loud the noise is, how long someone is exposed to it and, to some extent, individual susceptibility. The frequency or pitch can also have some effect on hearing loss, since high-pitched sounds are more damaging than low-pitched ones.

Exposure to a number of common industrial chemicals and some medications can also cause hearing loss or exacerbate the effects of noise on hearing. These substances are called ototoxic substances.

Ototoxic substances absorbed into the bloodstream may damage the cochlea in the inner ear and/or the auditory pathways to the brain, leading to hearing loss and tinnitus. Hearing loss is more likely if exposure is to a combination of substances or a combination of the substance and noise.

There is also some evidence that exposure to hand transmitted vibrations can exacerbate the effects of noise on hearing.

Further information on these other causes of hearing loss is provided in Appendix A.

Whether the exposure standard of 85 dB(A) averaged over eight hours is exceeded depends on the level of noise involved and how long workers are exposed to it.

Peak noise levels greater than 140 dB(C) usually occur with impact or explosive noise such as sledge-hammering or a gun shot. Any exposure above this peak can create almost instant damage to hearing.

Decibels are not like normal numbers. They can’t be added or subtracted in the normal way. The decibel scale is logarithmic. On this scale, an increase of 3 dB therefore represents a doubling or twice as much sound energy. This means that the length of time a worker could be exposed to the noise is reduced by half for every 3 dB increase in noise level if the same noise energy is to be received.

Table 1 below demonstrates the length of time a person without hearing protectors can be exposed before the standard is exceeded.

Table 1 Equivalent noise exposures

LAeq,8h = 85 dB(A) |

Noise Level dB(A) | Exposure Time |

80 | 16 hours |

82 | 12hours |

85 | 8 hours |

88 | 4 hours |

91 | 2 hours |

94 | 1 hour |

97 | 30 minutes |

100 | 15 minutes |

103 | 7.5 minutes |

106 | 3.8 minutes |

109 | 1.9 minutes |

112 | 57 seconds |

115 | 28.8 seconds |

118 | 14.4 seconds |

121 | 7.2 seconds |

124 | 3.6 seconds |

127 | 1.8 seconds |

130 | 0.9 seconds |

Essentially, a worker who is exposed to 85 dB(A) for 8 hours receives the same noise energy as someone exposed to 88 dB(A) for 4 hours, with the balance of the day in a very quiet environment. In both cases the exposure standard is not being exceeded. However, being exposed to 88 dB(A) for more than 4 hours would mean that the standard is exceeded. Similarly, if a worker is using a machine that generates 121 dB(A) then the exposure standard would be exceeded after only 7.2 seconds.

There is a big range in different people’s susceptibility to hearing loss from noise. Research shows that 8-hour average daily noise exposure levels below 75 dB(A) or instantaneous peak noise levels below 130 dB(C) are unlikely to cause hearing loss. With progressively increasing levels, the risk becomes greater.

The WHS Regulations set the exposure standard for noise at an LAeq,8h of 85 dB(A) and a peak noise level at 140 dB(C), which protects most but not all people. Therefore, workplace noise should be kept lower than the exposure standard for noise if reasonably practicable.

Noise at levels that do not damage hearing can have other adverse health effects. This can arise when noise chronically interferes with concentration and communication. Persistent noise stress can increase the risk of fatigue and cardiovascular disorders including high blood pressure and heart disease.

Although safe levels to guard against these effects have not yet been fully determined, as a guide, the risk of adverse health effects can be minimised by keeping noise levels below:

- 50 dB(A) where work is being carried out that requires high concentration or effortless conversation

- 70 dB(A) where more routine work is being carried out that requires speed or attentiveness or where it is important to carry on conversations.

These levels include the noise from other work being carried out within the workplace.

To work safely, workers must be able to hear warning signals above any other noise (ambient noise) at the workplace. For reversing alarms on mobile plant, the guidance in ISO:9533: 2010 Earth-moving machinery – Machine-mounted audible travel alarms and forward horns – Test methods and performance criteria should be followed. This requires the noise level of the alarm at potential reception points to be at least as high as the noise from the engine under high idle.

For other situations, the levels needed are higher – at least 65 dB(A) and more than 15 dB(A) greater than the ambient noise level at any position in the signal reception area. More detailed guidance on assessing the audibility of warning signals can be found in ISO 7731:2003 Ergonomics – Danger signals for public and work areas – Auditory danger signals.

The potential for noise to be hazardous is not always obvious. Hazard identification is a way of finding out which work activities have the potential to contribute to hearing loss or other harm caused by noise.

Exposure to noise is cumulative and a worker may perform a number of noisy work activities over time which, in combination, may expose the worker to hazardous noise.

You may not need specialist skills to identify sources of hazardous noise, but you must undertake the process in consultation with your workers and their health and safety representatives. As a guide, if you need to raise your voice to communicate with someone about one metre away, the noise is likely to be hazardous to hearing.

A checklist is provided in Appendix B to help you further with this process.

Regularly walking around the workplace, talking to workers and observing how things are done can help you identify noise hazards. Find out where noise is coming from and which tasks or processes produce noise. Take immediate action to control noise where this is possible, for example fix loose panels that are vibrating and rattling during machine operation.

Information regarding noise levels from the manufacturers or suppliers of plant and equipment used at the workplace should be obtained.

Information and advice about hazards and risks relevant to particular industries and work activities is also available from regulators, industry associations, unions, technical specialists and safety consultants.

You should check whether any workers’ compensation claims have been made for hearing loss and if any hearing loss or tinnitus has been found during repeat audiometric testing. If a worker’s hearing has been affected and has been attributed to a particular task, then a hazard may exist that could affect other workers.

Table 2 below lists common noise sources and their typical sound levels which can be used to compare whether noise in the workplace sounds as loud as or louder than 85 dB(A).

Table 2 Common noise sources and their typical sound levels

Typical sound level in dB | Sound source |

140 | Jet engine at 30m |

130 | Rivet hammer (pain can be felt at this threshold) |

120 | Rock drill |

110 | Chain saw |

100 | Sheet-metal workshop |

90 | Lawn-mower |

85 | Front-end loader |

80 | Kerbside Heavy traffic |

Lathe |

70 | Loud conversation |

60 | Normal conversation |

40 | Quiet radio music |

30 | Whispering |

0 | Hearing threshold |

In consultation with your workers and health and safety representatives, make a list of all noisy activities that may pose a risk to the health and safety of persons at the workplace. If you have answered ‘yes’ to any of the questions in Appendix B, it is likely that your workers are being exposed to hazardous noise. If you are unsure about the level of exposure or how to eliminate or minimise the risks effectively, you should take the next step to assess the risks of hearing loss.

If you have identified any noisy activities that may expose your workers or other people at your workplace to hazardous noise then, unless you can reduce the exposures to below the standard immediately, you should assess the risks by carrying out a noise assessment.

A noise assessment will help you:

- identify which workers are at risk of hearing loss

- determine what noise sources and processes are causing that risk

- identify if and what kind of noise control measures could be implemented

- check the effectiveness of existing control measures.

A noise assessment may not always need measurement. For example, if only one activity at the workplace – the use of a single machine – involves noise above 85 dB(A) and the manufacturer has provided information about the machine’s noise levels when it is operated in particular ways, then a sufficient assessment can be made without measurement. More complex situations may require measurement to accurately determine a worker’s exposure to noise, such as workplaces with variable noise levels over a shift and jobs where workers move in and out of noisy areas.

A noise assessment should be done by a competent person in accordance with the procedures in AS/NZS 1269.1 Measurement and assessment of noise immission and exposure. The more complex the situation, the more knowledgeable and experienced the person needs to be.

A competent person is one who has accurately calibrated noise measuring instruments and, through training and experience:

- understands what is required by the WHS Regulations for noise

- knows how to check the performance of the instruments

- knows how to take the measurements properly

- can interpret the results of the noise measurements.

The way a noise assessment is done will depend upon:

- the type of workplace

- the number of persons potentially at risk from exposure to hazardous noise

- the information already available on noise at the workplace.

A noise assessment should be done during a typical working shift and should determine:

- the noise levels produced during various tasks carried out during the shift

- how long your workers are exposed to noise during each of these tasks.

An assessment should take into account:

- plant, equipment and other sources of noise in operation at the workplace

- how work activities are carried out

- the length of the shift

- environmental factors (e.g. types of walls, surfaces, layout of work stations).

This means that adequate information about the tasks and their frequency is needed, so consultation with workers and their supervisors is essential.

Noise measurements should be taken at 0.1 to 0.2 metres from the worker’s ear canal entrance over a period of time that is representative of the noise produced during the tasks.

In most situations the use of a hand-held integrating sound level meter will produce the most useful information for choosing appropriate noise control measures. In situations where workers are highly mobile or access for the person taking the measurement is difficult or unsafe, it may be more appropriate to use personal sound exposure meters (dose meters).

Noise measurements should include the combined noise levels of all the tools, machines and processes present as well as the background noise from ventilation systems, cooling compressors, circulation pumps, etc. To identify which noise sources contribute most to workers’ exposures, the noise from each source or work activity should also be measured separately.

The Ready Reckoner in Appendix C may be used to work out the total LAeq,8h for combinations of noise levels and exposure duration for each work activity and the relative importance of each.

If a group of workers is exposed to identical sources of noise and their exposure is likely to be the same, then you do not need a separate assessment for each worker. A representative assessment can be done for one or more of the workers.

Shift durations of 10 hours or longer involve a degree of risk greater than that indicated by the 8 hour measurement LAeq,8h. This increase in risk arises because of the additional damaging effect of continuous exposure to noise after 10 hours. The risk may be further increased if there is reduced recovery time between successive shifts.

If workers work shifts of 10 hours or more, the adjustment factor for extended shifts as set out in AS/NZS 1269.1 (see Table 3) should be added to the measured LAeq,8h before comparing it with the 85 dB(A) exposure standard for noise.

Table 3 Adjustments to LAeq,8h for extended work shifts

Shift length | Adjustment added to measured

LAeq,8h dB(A) |

10 hrs or more to less than 14 hrs | + 1 |

14 hrs or more to less than 20 hrs | + 2 |

20 hrs or more | + 3 |

For example, if a worker works 12-hour shifts and the typical LAeq,8h has been determined to be 93 dB(A), an additional one decibel is added to give an adjusted LAeq,8h of 94 dB(A). Hence the worker‘s LAeq,8h exceeds the exposure standard for noise by 9 dB(A). For a fully worked example see Appendix C.

If workers work more than five days per week, the weekly averaging procedure of AS/NZS 1269.1 should be used.

Noise assessment reports should show that the assessment was done properly and that all factors were taken into account. An assessment report should contain all the information shown in Appendix D. Noise assessment reports should be used to select appropriate control measures. The main findings should be included in training for all workers. The reports should be made available to managers, health and safety representatives and regulators.

The most important step in the risk management process involves eliminating the risks, or if that is not reasonably practicable, minimising the risks so far as is reasonably practicable.

The WHS Regulations require duty holders to work through a hierarchy of control to choose the control measure that most effectively eliminates or minimises the risk in the circumstances. The hierarchy ranks the ways of controlling the risk of hearing loss from noise from the highest level of protection and reliability to the lowest so that the most effective controls are considered first.

Effective risk control may involve a single control measure or a combination of two or more different controls.

The most effective control measure is to eliminate the source of noise completely, for example by ceasing to use a noisy machine, changing the way work is carried out so hazardous noise is not produced or by not introducing the hazard into the workplace.

If it is not reasonably practicable to eliminate the source of noise, you must minimise the risk associated with hearing loss so far as is reasonably practicable. This includes ensuring that the noise does not exceed the exposure standard by choosing one or more of the following measures:

- substitute the hazard with plant or processes that are quieter

- modify plant and processes to reduce the noise using engineering controls

- isolate the source of noise from people by using distance, barriers, enclosures and sound-absorbing surfaces.

If there is a remaining risk, it must be minimised so far as is reasonably practicable by implementing administrative controls, and if a risk still remains, then suitable personal protective equipment must be provided and used. These two types of control measures, when used on their own, tend to be least effective in minimising risks because they rely on human behaviour and supervision.

One of the most cost-effective and long-term ways of reducing noise at work is to introduce a purchasing and hiring policy to choose the quietest plant for the job. This can be done by obtaining information on noise emission (for example, data on sound power level or sound pressure level at the operator position) from the manufacturer, importer or supplier of plant and comparing it to determine the quietest plant.

Ask the suppliers about the likely noise emission under the particular conditions in which you will operate the machinery, as well as under standard test conditions. If you ask the same question to all suppliers you can compare information. Sound power level data will only ever be a guide as many factors affect the actual noise levels experienced by your workers, but it will help you buy quieter machines.

You should purchase or hire only from suppliers who can demonstrate a low noise design, with noise control as a standard part of the machine, not as an optional extra.

A different way of doing the job may provide the same result with a lot less noise. For example, bending metal in a vice or a press is quieter than hammering it into shape, welding is generally quieter than riveting, gluing is quieter than hammering in nails, clipping is quieter than stapling, and lowering materials in a controlled manner is quieter than dropping them on hard surfaces.

A good understanding of the operation of the plant or process is necessary when considering ways of minimising noise at its source.

Examples of engineering control measures include:

- eliminating impacts between hard objects or surfaces

- minimising the drop height of objects or the angle that they fall onto hard surfaces

- using absorbent lining on surfaces to cushion the fall or impact of objects

- fitting exhaust mufflers on internal combustion engines

- fitting silencers to compressed air exhausts and blowing nozzles

- isolating a vibrating noise source to separate it from the surface on which it is mounted using rubber mounts and flexible connections

- ensuring gears mesh together better

- fixing damping materials (such as rubber) or stiffening to panels to reduce vibration

- fitting sound-absorbing materials to hard reflective surfaces

- turning down volume controls

- changing fan speeds or the speeds of particular components

- changing the material the equipment or its parts are made of (change metal components to plastic components).

Further information on using engineering controls is at Appendix E.

Examples of isolating the source of noise from workers include:

- building enclosures or sound proof covers around noise sources

- using barriers or screens to block the direct path of sound

- locating noise sources further away from workers (see Figure 1)

- using remote controls to operate noisy plant from a distance.

Figure 1 Sound spreading in an open space away from reflecting surfaces and measured at a certain distance from the source is reduced by about 6 dB for each doubling of that distance. Sound is reduced less when spreading inside an enclosed space.

If a small sound source produces a sound level of 90 dB(A) at a distance of 1 metre, the sound level at 2 metres distance is 84 dB(A), and at 4 metres is 78 dB(A), etc.

Regular maintenance of plant and equipment is essential as it will deteriorate with age and can become noisier. Check for changes in noise levels – badly worn bearings and gears, poor lubrication, blunt blades, loose parts, unbalanced rotating parts and steam or air leaks all create noise that can be reduced with good maintenance. Engineering controls such as vibration mountings, impact absorbers, gaskets, seals, silencers, barriers and other equipment should be regularly inspected and maintained.

Administrative noise control measures reduce the amount of noise to which a person is exposed by reducing the time they are exposed to it. Examples include:

- organising schedules so that noisy work is done when only a few workers are present

- notifying workers and others in advance of noisy work so they can limit their exposure to it

- keeping workers out of noisy areas if their work does not require them to be there

- sign-posting noisy areas and restricting access

- providing quiet areas for rest breaks for workers exposed to noisy work

- limiting the time workers spend in noisy areas by moving them to quiet work before their daily noise exposure levels exceed the exposure standard.

If you rely on administrative controls, you should conduct regular checks to ensure that they are being complied with.

Regulation 44: If personal protective equipment (PPE) is to be used at the workplace, the person conducting the business or undertaking must ensure that the equipment is:

- selected to minimise risk to health and safety

- suitable for the nature of the work and any hazard associated with the work

- a suitable size and fit and reasonably comfortable for the person wearing it

- maintained, repaired or replaced so it continues to minimise the risk

- used or worn by the worker, so far as is reasonably practicable.

Regulation 46: A worker must, so far as reasonably able, wear the PPE in accordance with any information, training or reasonable instruction.

Personal hearing protectors, such as ear-muffs or ear-plugs, should be used in the following circumstances:

- when the risks arising from exposure to noise cannot be eliminated or minimised by other more effective control measures,

- as an interim measure until other control measures are implemented

- where extra protection is needed above what has been achieved using other noise control measures.

If the use of personal hearing protectors is necessary, it is important that the hearing protectors are worn throughout the period of exposure to noise. Removing personal hearing protectors for even short periods significantly reduces the effective attenuation (noise reduction) and might provide inadequate protection. For example, a worker wearing a hearing protector for a full 8-hour day will receive the 30 dB maximum protection level. However, one hour without wearing the hearing protector causes the maximum protection level to fall to 9 dB.

Areas where people may be exposed to hazardous noise should be sign-posted as hearing protector areas and the boundaries of these areas should be clearly defined. Workers and other persons, including managers and visitors, should not enter these areas without wearing appropriate personal hearing protectors, regardless of how short the time they stay in the hearing protector area.

Where sign-posting is not practicable, you should make other arrangements to ensure that workers and others know when personal hearing protectors are required. For example:

- attach prominent warning notices to tools and equipment indicating that personal hearing protectors should be worn when operating them

- provide written and verbal instructions on how to recognise circumstances in which personal hearing protectors are needed

- ensure effective supervision of identified hazardous tasks.

Personal hearing protectors should be selected and maintained in accordance with AS/NZS 1269.3 Occupational noise management – hearing protector program. Involve your workers in the selection process and offer a reasonable choice from a range of types.

Suppliers of hearing protectors should provide the full information on the attenuation likely to be provided including the SLC80 ratings, class and octave band attenuation values. The attenuation values should be derived from attenuation measurements made in accordance with AS/NZS 1270 Acoustics – hearing protectors.

When selecting personal hearing protectors you should consider:

- the degree of attenuation required in the worker’s environment (see Table 4). Do not provide protectors that overprotect by cutting out too much sound – this can cause difficulties hearing verbal instructions and other sounds needed to work safely

- the suitability for the type of working environment and the work tasks. For example, ear-plugs are difficult to use hygienically for work that requires them to be inserted with dirty hands and in these circumstances, ear-muffs are more appropriate, but ear-muffs can be uncomfortable to wear in hot environments and can make it difficult for the wearer to enter a confined space or to wear a helmet

- the comfort, weight and clamping force of the personal hearing protector.

Table 4 Recommended class of hearing protector

Measured exposure

LAeq,8h dB(A) | Class |

Less than 90 | 1 |

90 to less than 95 | 2 |

95 to less than 100 | 3 |

100 to less than 105 | 4 |

105 to less than 110 | 5 |

Individual fit of personal hearing protectors is critical for optimum protection. Several devices are available to assist with this. Wearing work equipment—such as hard hats, dust masks and eye protection—may affect the performance of the protector. The fit of hearing protectors should be checked while the user is wearing regular work equipment. Workers wearing spectacles should be fitted with hearing protectors while wearing the spectacles.

Personal hearing protectors must be regularly inspected and maintained to ensure they remain in good, clean condition. The inspections should check that:

- ear-muff seals are undamaged

- the tension of headbands is not reduced

- there are no unofficial modifications

- compressible ear-plugs are soft, pliable and clean.

If disposable ear-plugs are used, they should only be worn once.

You must provide your workers with training, information and instruction in the proper use, fit, care and maintenance of personal hearing protectors. You should also:

- include the need to wear hearing protectors in your safety procedures

- place someone in charge of issuing and making sure replacements are readily available

- carry out spot checks to ensure that workers are wearing their hearing protectors when required and are using them correctly

- ensure all managers and supervisors set a good example and wear personal hearing protectors at all times when in hearing protector areas.

Regulation 58: A person conducting a business or undertaking must provide audiometric testing for a worker who is carrying out work for the business or undertaking if the worker is required to frequently use personal hearing protectors as a control measure for noise that exceeds the exposure standard.

Audiometric testing must be provided within three months of the worker commencing work. Starting the audiometric testing before people are exposed to hazardous noise (such as new starters or those changing jobs) provides a baseline as a reference for future audiometric test results. Regular follow-up tests must be carried out at least every two years. These should be undertaken well into the work shift so that any temporary hearing loss can be picked up.

More frequent audiometric testing (e.g. every six months) may be needed if exposures are at a high LAeq,8h, which is equal or greater than 100 dB(A).

Before introducing an audiometric testing program, you must consult with your workers and their health and safety representatives. It is important that your workers understand that the aim of the testing is to evaluate the effectiveness of control measures to protect their hearing.

Audiometric testing and assessment of audiograms should be carried out by competent persons in accordance with the procedures in AS/NZS 1269.4:2005 - Occupational noise management - Auditory assessment.

Workers should be given the results of audiometric testing accompanied by a written explanation of the meaning and implications. Only with the consent of the worker should you provide their results to other parties. Unidentifiable individual results and group data should be made available to health and safety representatives of the worker’s work group.

The reasons for any changes in hearing levels over time should be thoroughly investigated.

When temporary or permanent threshold shifts are revealed through audiometric assessments or a worker reports a recent diagnosis of tinnitus, you must review your control measures to determine whether more effective control measures can be implemented so that your workers do not have to rely on personal hearing protectors.

If the worker is to continue using personal hearing protectors, you should:

- verify that the nominal performance of the worker’s personal hearing protector is adequate for the level of exposure to noise

- examine the protector carefully and ensure it is not damaged

- check the protector fits the worker closely with no leakage paths for noise

- ask the worker if they have any difficulty using the protector

- check the worker uses the protector correctly and consistently whilst performing their work.

If workers are found to have sufficient hearing loss to interfere with the safe performance of their work, all reasonably practicable steps should be taken to modify the work environment. This may include providing:

- volume control on equipment such as telephones

- acoustically treated meeting areas with low noise and low sound reflections

- supplementary visual warning signals

- alternative work for the worker if other measures do not remedy the situation.

Monitoring hearing with regular audiometric testing is recommended in situations where workers are exposed to:

- any of the ototoxic substances listed in Appendix A where the airborne exposure (without regard to respiratory protection worn) is greater than 50 per cent of the national exposure standard for the substance, regardless of the noise level

- ototoxic substances at any level and noise with LAeq,8h greater than 80 dB(A) or LC,peak greater than 135 dB(C)

- hand-arm vibration at any level and noise with LAeq,8h greater than 80 dB(A) or LC,peak greater than 135 dB(C).

Section 19: A person conducting a business or undertaking must ensure, so far as is reasonably practicable, that information, training and instruction is provided to workers and others at the workplace to protect them from health and safety risks.

Regulation 39: The information, training and instruction must, so far as is reasonably practicable, be provided in a way that can be easily understood by any person to whom it is provided.

Training should be provided to:

- those workers who may be exposed to hazardous noise or other agents that may contribute to hearing loss

- their managers and supervisors

- workplace health and safety committees and health and safety representatives

- those responsible for the purchase of plant, noise control equipment, personal hearing protectors and for the design, scheduling, organisation and layout of work.

The contents of the training program should include:

- the health and safety responsibilities of each party at the workplace

- how hearing can be affected by exposure to noise

- the detrimental effects hearing loss and tinnitus have on the quality of life, both at work and socially

- the tasks at the workplace that have the potential to give rise to hearing loss and the likely noise exposure level

- how to use noise control measures

- how to select, fit, wear, maintain and store personal hearing protectors

- how to report defects in hearing protectors and noise control equipment or raise any concerns regarding hazardous noise

- the purpose and nature of audiometric testing.

A noise management plan may help implement the chosen noise control measures effectively. It should identify what action needs to be taken, who will be responsible for taking the action and by when.

After an acoustic incident, the worker should:

- remove the headset immediately

- in some circumstances, move to the ‘break out’ area

- report the incident and any symptoms to the supervisor

- discuss with the supervisor their ability to continue work and, where appropriate, relocate to another workstation.

After an acoustic incident, you should:

- ensure the event is recorded and logged

- discuss the incident and ability to continue work with the worker

- where symptoms are persistent or severe, refer the worker to a general practitioner and/or an audiologist for assessment and treatment of possible injury

- enquire into the cause of the noise, including whether it is from an internal or external source

- ensure the headset and other equipment is checked for clarity of sound and possible damage and faults

- remove damaged or faulty equipment from service

- review the adequacy of the noise control measures and general working environment.

Description of work location:_____________________________________________________

Activities at workstation:________________________________________________________

Assessed by:_________________________________________________________________

Date:_______________________________________________________________________

‘Yes’ to any of the following indicates the need to carry out a noise assessment if exposure to the noise cannot be immediately controlled.

Hazard identification questions | Yes | No |

- Is a raised voice needed to communicate with someone about one metre away?

| o | o |

2. Do your workers notice a reduction in hearing over the course of the day? (This may only become noticeable after work, for example, needing to turn up the radio on the way home) | o | o |

3. Are your workers using noisy powered tools or machinery? | o | o |

4. Are there noises due to impacts (such as hammering, pneumatic impact tools) or explosive sources (such as explosive powered tools, detonators)? | o | o |

5. Are personal hearing protectors used for some work? | o | o |

6. Do your workers complain that there is too much noise or that they can’t clearly hear instructions or warning signals? | o | o |

7. Do your workers experience ringing in the ears or a noise sounding different in each ear? | o | o |

8. Do any long-term workers appear to be hard of hearing? | o | o |

9. Have there been any workers’ compensation claims for noise-induced hearing loss? | o | o |

10. Does any equipment have manufacturer’s information (including labels) indicating noise levels equal or greater than any of the following: | | |

(a) 80 dB(A) LAeq,T (T= time period over which noise is measured)? | o | o |

(b) 130 dB(C) peak noise level? | o | o |

(c) 88 dB(A) sound power level? | o | o |

11. Do the results of audiometry tests indicate that past or present workers have hearing loss? | o | o |

13. Are any workers exposed to noise and ototoxins in the workplace? | o | o |

14. Are any workers exposed to noise and hand-arm vibration? | o | o |

Tables C1 to C3 provide a simple way of working out a worker’s LAeq,8h (eight-hour equivalent continuous sound pressure level) if you know the noise level and duration of each of the noisy tasks carried out by the worker during the work shift.

From Tables C1 or C2 you read off the number of “noise exposure points” that correspond to a particular task’s noise level and exposure duration. Table C1 is for noise levels between 75 and 105 dB(A) and Table C2 is for higher noise levels between 95 and 125 dB(A).

For example, a task producing a noise level at the worker’s ear of 93 dB(A) that is done for two lots of 30 minutes in a shift (i.e. one hour total) produces 80 noise exposure points. Another task with a noise level of 120 dB(A) for one minute during the shift produces 670 points.

These points can be added (in the normal arithmetic way) to give the total exposure points for the shift. Table C3 is then used to convert the total points to the LAeq,8h.

In the example above, if these were the only noisy tasks carried out by the worker, the points total is 750 and (from Table C3, rounding to the nearest whole decibel) the LAeq,8h for the worker is 94 dB(A).

This calculated LAeq,8h value can be compared with the exposure standard for noise i.e. LAeq,8h = 85 dB(A). Additionally, noise exposure points can be used to prioritise the noise control program by showing which tasks make the greatest contribution to the total noise exposure.

In the example above the worker’s LAeq,8h is greater than the standard, so noise control action is needed. Although it only lasts for one minute, the 120 dB(A) task contributes more than eight times as much as the other task to the total exposure and so should be the first one tackled.

In this scheme the exposure standard for noise – LAeq,8h = 85 dB(A) – is 100 points.

Table C1 Exposure points for 75-105 dB(A)/15minutes – 12 hours

Sound Level LAeq,T dB(A) | Duration of exposure per shift |

15 min | 30 min | 1 h | 2 h | 4 h | 8 h | 10 h* | 12 h* |

105 | 320 | 640 | 1270 | 2530 | 5060 | 10120 | 12650 | 15180 |

104 | 250 | 500 | 1000 | 2010 | 4020 | 8040 | 10050 | 12060 |

103 | 200 | 400 | 800 | 1600 | 3200 | 6400 | 8000 | 9600 |

102 | 160 | 320 | 640 | 1270 | 2540 | 5070 | 6340 | 7600 |

101 | 130 | 250 | 500 | 1010 | 2010 | 4030 | 5040 | 6040 |

100 | 100 | 200 | 400 | 800 | 1600 | 3200 | 4000 | 4800 |

99 | 80 | 160 | 320 | 640 | 1270 | 2540 | 3180 | 3810 |

98 | 63 | 130 | 250 | 500 | 1010 | 2020 | 2520 | 3030 |

97 | 50 | 100 | 200 | 400 | 800 | 1600 | 2000 | 2410 |

96 | 40 | 80 | 160 | 320 | 640 | 1270 | 1590 | 1910 |

95 | 32 | 63 | 130 | 250 | 510 | 1010 | 1260 | 1520 |

94 | 25 | 50 | 100 | 200 | 400 | 800 | 1000 | 1210 |

93 | 20 | 40 | 80 | 160 | 320 | 640 | 800 | 960 |

92 | 16 | 32 | 63 | 130 | 250 | 510 | 630 | 760 |

91 | 13 | 25 | 50 | 100 | 200 | 400 | 500 | 600 |

90 | 10 | 20 | 40 | 80 | 160 | 320 | 400 | 480 |

89 | 7.9 | 16 | 32 | 64 | 130 | 250 | 320 | 380 |

88 | 6.3 | 13 | 25 | 50 | 100 | 200 | 250 | 300 |

87 | 5.0 | 10 | 20 | 40 | 80 | 160 | 200 | 240 |

86 | 4.0 | 8.0 | 16 | 32 | 64 | 130 | 160 | 190 |

85 | 3.2 | 6.3 | 13 | 25 | 50 | 100 | 130 | 150 |

84 | 2.5 | 5.0 | 10 | 20 | 40 | 80 | 100 | 120 |

83 | 2.0 | 4.0 | 8.0 | 16 | 32 | 64 | 80 | 96 |

82 | 1.6 | 3.2 | 6.3 | 13 | 25 | 51 | 63 | 76 |

81 | 1.3 | 2.5 | 5.0 | 10 | 20 | 40 | 50 | 60 |

80 | 1.0 | 2.0 | 4.0 | 8.0 | 16 | 32 | 40 | 48 |

79 | 0.8 | 1.6 | 3.2 | 6.4 | 13 | 25 | 32 | 38 |

78 | 0.6 | 1.3 | 2.5 | 5.0 | 10 | 20 | 25 | 30 |

77 | 0.5 | 1.0 | 2.0 | 4.0 | 8.0 | 16 | 20 | 24 |

76 | 0.4 | 0.8 | 1.6 | 3.2 | 6.4 | 13 | 16 | 19 |

75 | 0.3 | 0.6 | 1.3 | 2.5 | 5.1 | 10 | 13 | 15 |

Table C2 Exposure points for 95-125 dB(A)/5 seconds – 10 minutes

Sound Level LAeq,T dB(A) | Duration of exposure per shift |

5 sec | 10 sec | 15 sec | 30 sec | 1 min | 2 min | 5 min | 10 min |

125 | 180 | 360 | 530 | 1050 | 2110 | 4220 | 10540 | 21080 |

124 | 140 | 280 | 420 | 840 | 1680 | 3350 | 8370 | 16750 |

123 | 110 | 220 | 330 | 670 | 1330 | 2660 | 6650 | 13300 |

122 | 90 | 180 | 260 | 530 | 1060 | 2110 | 5280 | 10570 |

121 | 70 | 140 | 210 | 420 | 840 | 1680 | 4200 | 8390 |

120 | 56 | 110 | 170 | 330 | 670 | 1330 | 3330 | 6670 |

119 | 44 | 88 | 130 | 270 | 530 | 1060 | 2650 | 5300 |

118 | 35 | 70 | 110 | 210 | 420 | 840 | 2100 | 4210 |

117 | 28 | 56 | 84 | 170 | 330 | 670 | 1670 | 3340 |

116 | 22 | 44 | 66 | 130 | 270 | 530 | 1330 | 2650 |

115 | 18 | 35 | 53 | 110 | 210 | 420 | 1050 | 2110 |

114 | 14 | 28 | 42 | 84 | 170 | 330 | 840 | 1680 |

113 | 11 | 22 | 33 | 67 | 130 | 270 | 670 | 1330 |

112 | 8.8 | 18 | 26 | 53 | 110 | 210 | 530 | 1060 |

111 | 7.0 | 14 | 21 | 42 | 84 | 170 | 420 | 840 |

110 | 5.6 | 11 | 17 | 33 | 67 | 130 | 330 | 670 |

109 | 4.4 | 8.8 | 13 | 26 | 53 | 110 | 270 | 530 |

108 | 3.5 | 7.0 | 11 | 21 | 42 | 84 | 210 | 420 |

107 | 2.8 | 5.6 | 8.4 | 17 | 33 | 67 | 170 | 330 |

106 | 2.2 | 4.4 | 6.6 | 13 | 27 | 53 | 130 | 270 |

105 | 1.8 | 3.5 | 5.3 | 11 | 21 | 42 | 110 | 210 |

104 | 1.4 | 2.8 | 4.2 | 8.4 | 17 | 33 | 84 | 170 |

103 | 1.1 | 2.2 | 3.3 | 6.7 | 13 | 27 | 67 | 130 |

102 | 0.9 | 1.8 | 2.6 | 5.3 | 11 | 21 | 53 | 110 |

101 | 0.7 | 1.4 | 2.1 | 4.2 | 8.4 | 17 | 42 | 84 |

100 | 0.6 | 1.1 | 1.7 | 3.3 | 6.7 | 13 | 33 | 67 |

99 | 0.5 | 0.9 | 1.3 | 2.7 | 5.3 | 11 | 27 | 53 |

98 | 0.4 | 0.7 | 1.1 | 2.1 | 4.2 | 8.4 | 21 | 42 |

97 | 0.3 | 0.6 | 0.8 | 1.7 | 3.3 | 6.7 | 17 | 33 |

96 | 0.2 | 0.5 | 0.7 | 1.3 | 2.7 | 5.3 | 13 | 27 |

95 | 0.2 | 0.4 | 0.5 | 1.1 | 2.1 | 4.2 | 11 | 21 |

Table C3 Conversion |

Total exposure points | LAeq,8h dB(A) |

32000 | 110 |

25420 | 109 |

20190 | 108 |

16040 | 107 |

12740 | 106 |

10120 | 105 |

8040 | 104 |

6400 | 103 |

5070 | 102 |

4030 | 101 |

3200 | 100 |

2540 | 99 |

2020 | 98 |

1600 | 97 |

1270 | 96 |

1010 | 95 |

800 | 94 |

640 | 93 |

510 | 92 |

400 | 91 |

320 | 90 |

250 | 89 |

200 | 88 |

160 | 87 |

130 | 86 |

100 | 85 |

80 | 84 |

64 | 83 |

51 | 82 |

40 | 81 |

32 | 80 |

25 | 79 |

20 | 78 |

16 | 77 |

13 | 76 |

10 | 75 |

Notes:

- If there is only one source of noise exposure, a quick glance at the background colour of the table cell corresponding to the sound level and duration of exposure will tell you if the worker is:

(a) above the LAeq,8h 85 dB(A) exposure standard - Red

(b) well below the LAeq,8h 85 dB(A) standard - Green

(c) marginal (between LAeq,8h 80 and 85 dB(A)) – Yellow

2. For durations of exposure not listed in the table, add together the points from two durations that together give the same duration. For example, for five hours at 95 dB(A), add together the points for four hours at 95 dB(A) and one hour at 95 dB(A), i.e. 510 + 130, giving a total of 640 points.

3. The tables can be extended to include both higher and lower sound levels. A change of 10 dB(A) results in a tenfold change in the points. For example, one hour exposure at 108 dB(A) will give 10 times the points for one hour at 98 dB(A), that is, 2500 points.

4. For shift lengths of 10 hours or more (*), the adjustments listed in Table 3 should be added to the LAeq,8h before comparing the result with the exposure standard for noise.

Example: Carpenter working a 10.5-hour shift using tools and machines listed below.

Machine/Process | Measured Sound LevelLAeq,T dB(A) | Duration per shift |

Circular Saw – cutting hardwood | 94 | 2 h |

Planer – planing hardwood | 100 | 3 h |

Power Drill – drilling hardwood | 87 | 4 h |

Hammering nails into wood | 98 | 10 min |

Background | 70 | 1 h 20 min |

If you want to just quickly see if the carpenter is exposed above the LAeq,8h = 85 dB(A) noise standard, look up points for 94 dB(A) and 2 h in Table C1. You will see that the cell is red, so you know without going any further that the carpenter is exposed to noise above the standard.

If you want to actually work out the carpenter’s 8h-equivalent continuous noise level, LAeq,8h, then use Tables C1, C2 and C3 as below:

Machine/Process | Sound LevelLAeq,T dB(A) | Duration per shift | Points |

Circular Saw – cutting hardwood | 94 | 2 h | |

Planer – planing hardwood | 100 | 3 h | |

Power Drill – drilling hardwood | 87 | 4 h | 80 |

Hammering nails into wood | 98 | 10 min | 42 |

Background | 70 | 1 h 20 min | 1 h 0.4 20 m 0.1 |

| | | Total 1522.5 |

From Table C3: LAeq,8h = 97 dB(A), but as the shift is 10.5 hours, an adjustment of +1 dB(A) is needed, hence the adjusted LAeq,8h = 98 dB(A).

Checklist: What should be included in a noise assessment report? | If present |

When | |

Date of Assessment | o |

Who | |

Name of Assessor | o |

Information (background/qualifications) of assessor | o |

Equipment used | |

Type of equipment used to take measurements | o |

Calibration details for equipment | o |

How the noise measurements were taken | |

Where measurements were taken (general area or operator ear position) | o |

Period of time over which the measurements were taken | o |

What was assessed | |

The area, plant, process, activity and workers that were assessed | o |

Source of noise | |

The sources (plant/process/jobs) of the noise | o |

Whether all the noise sources that may be operating at the time were taken into account | o |

Whether there were any significant noise sources that were not operating during the assessment | o |

Systems of work | |

Brief description of the work activity (how it’s done; plant/process/activity/operating conditions/duration of process etc) | o |

Hours of workshift (eg 8-hour or 12-hour shift) | o |

Whether assessment is for a normal/typical day or for a worst case scenario | o |

Results | |

The results of measurements in terms of levels and durations | o |

Interpretation of the results, (i.e. compared to exposure standards; what do the results mean etc.; ranking of noise sources) | o |

Action Required | |

Any obvious noise controls that could be implemented, or the need for more detailed noise control study | o |

Other relevant factors | |

Information on and adequacy of any control measures already in place and hearing protectors used during the assessment | o |

Where relevant, information about the environment (types of walls, surfaces, buildings, operational state of machinery, etc.) | o |

The following are 10 simple noise control techniques that have wide application across industry.

In many cases they will produce substantial noise reductions quickly and cheaply, with little or no effect on normal operation or use of plant.

Typical applications - Chutes, hoppers, machine guards, panels, conveyors, tanks

Technique

There are 2 basic techniques:-

- unconstrained layer damping where a layer of bitumastic (or similar) high damping material is stuck to the surface

- constrained layer damping where a laminate is constructed

Constrained layer damping is more rugged and generally more effective. Either re-manufacture guards, panels or other components from commercially available sound deadened steel or buy self-adhesive steel sheet. The latter can simply be stuck on to existing components (inside or outside) covering about 80% of the flat surface area to give a 5 - 25 dB reduction in the noise radiated (use a thickness that is 40 per cent to 100 per cent of the thickness of the panel to be treated).

Limitations: the efficiency falls off for thicker sheets. Above about 3mm sheet thickness it becomes increasingly difficult to achieve a substantial noise reduction.

Typical applications - Axial flow or centrifugal fans.

Technique

Maximum fan efficiency coincides with minimum noise. Any fan installation feature that tends to reduce fan efficiency is therefore likely to increase noise. Two of the most common examples are bends close to the fan (intake side in particular) and dampers close to the fan intake or exhaust.

Ideally, for maximum fan efficiency and minimum noise, make sure there is at least 2 - 3 duct diameters of straight duct between any feature that may disturb the flow and the fan itself.

Noise reductions of 3 -12 dB are often possible.

3. DUCTWORK

Typical applications - Extraction, ventilation, cooling, openings in walls and enclosures.

Technique

Instead of fitting silencers, it is often possible to achieve a 10 - 20 dB reduction in airborne noise from a duct or opening by lining the last bend in the ductwork with acoustic absorbent (foam or rockwool / fibreglass). Alternatively, construct a simple absorbent lined right-angled bend to fit on the opening. Ideally, either side of the bend should be lined along a length equivalent to twice the duct diameter. Where flow velocities are high (> 3m/s), consider using cloth faced absorbent. Duct vibration can usually be treated by damping (as above).

4. FAN SPEED

Typical applications - Axial or centrifugal flow fans.

Technique

Fan noise is roughly proportional to the 5th power of fan speed. So in many cases it is possible to achieve a large noise reduction from a small drop in fan speed by changing control systems or pulley sizes and re-setting dampers. The following table provides a guide to the trade-off that can be expected.

FAN SPEED REDUCTION | NOISE REDUCTION |

10% | 2 dB |

20% | 5 dB |

30% | 8 dB |

40% | 11 dB |

50% | 15 dB |

5. PNEUMATIC EXHAUSTS

Technique

Almost invariably it is possible to reduce pneumatic exhaust noise permanently by 10 - 30 dB by fitting effective silencers. The following are the practical points that can make the difference between success and failure:-

— back pressure : fit a larger coupling and silencer

— clogging : fit a straight-through silencer that cannot clog (and has no back pressure)

— multiple exhausts : manifold them into a single, larger diameter pipe fitted with the rear silencer from virtually any make of car (from your local tyre and exhaust fitter). Typically 25 dB reduction.

Note : a well designed silencer will not increase system back pressure.

6. PNEUMATIC NOZZLES

Typical applications - Cooling, drying, blowing

Technique

In most cases, it is possible to replace existing nozzles (usually simple copper pipe outlets) for quiet, high efficiency units. These not only reduce noise levels by up to 10 dB, but also use less compressed air. The types of nozzle to look out for are entraining units (schematic at right) from various manufacturers and in a variety of sizes.

7. VIBRATION ISOLATION PADS

Typical applications - Machine feet, pumps, mezzanine installations

Technique

Mounting motors, pumps, gearboxes and other items of plant on rubber bonded cork (or similar) pads can be a very effective way of reducing transmission of vibration and therefore noise radiated by the rest of the structure. This is particularly the case where vibrating units are bolted to steel supports or floors. However, a common error with the use of these pads is for the bolt to ”short-circuit” the pad, resulting in no isolation. Additional pads should be fitted under the bolt heads as shown.

There are many types of off-the-shelf anti-vibration mounts available, for instance rubber/neoprene or spring types. The type of isolator that is most appropriate will depend on, among other factors, the mass of the plant and the frequency of vibration to be isolated. Any supplier of anti-vibration mounts will be able to advise you on this.

8. EXISTING MACHINE GUARDS

Technique

The existing guards on many machines can often be improved to provide a significant noise reduction. The two principles involved, which must be used in combination, are:-

(i) Minimise gaps

Reducing by half the “gap” open area in a set of guards can reduce the noise by 3 dB. If you can reduce the openings (flexible seals, additional close fitting panels etc) by 90 per cent, then a 10 dB noise reduction is possible.

(ii) Acoustic absorbent

Lining a significant proportion of the inside of the guards with acoustic absorbent (foam, rockwool / fibreglass) will reduce the noise “trapped” by the guards.

Consequently, less noise will escape through any gaps. Failure to line the inside of the guards could result in an increase in noise at the operator’s position if the gaps have been minimised as in (i) above.

In most cases, both sets of modifications can be tested in mock-up form using cardboard (and wide tape) to extend the guarding and temporarily fitting areas of acoustic foam inside. Not only does this process help with the practical aspects (access, visibility etc), but it usually also provides a very good indication of the noise reduction that can be expected. Guard vibration radiated as noise can also be treated via damping (as above).

9. CHAIN & TIMING BELT DRIVES

Technique

Noisy chain drives can often be replaced directly with quieter timing belts. Within the range of timing belts available, there are also quiet designs that use different tooth profiles to minimise noise. There is also a new design of belt for applications where noise is critical which uses a chevron tooth pattern to provide very quiet running. Noise reductions in the range of 6 - 20 dB are often possible using this approach.

10. ELECTRIC MOTORS

Technique

Most companies have large numbers of electric motors used on anything from fans to pumps to machine tools. However, it is not very common knowledge that general duty motors are available (at little or no cost premium) that are up to 10 dB(A) or more quieter than typical units as direct replacements. The best approach is to feed these motors into the system over a period of time so that all replacement motors are quiet motors.

![]()