This Methodology Determination is the Carbon Credits (Carbon Farming Initiative) (Avoided Emissions from Diverting Legacy Waste from Landfill for Process Engineered Fuel Manufacture) Methodology Determination 2012.

This Methodology Determination is taken to commence on 1 July 2010.

This Methodology Determination applies to transitioning Greenhouse FriendlyTM projects that divert construction and demolition waste and commercial and industrial waste to a waste diversion facility, for the purpose of manufacturing process engineered fuel.

Act means the Carbon Credits (Carbon Farming Initiative) Act 2011 as in force from time to time.

biobased waste materials means waste containing degradable organic carbon.

CO2-e means the carbon dioxide equivalence.

commercial and industrial waste means legacy waste generated from fixed point sources related to manufacturing, wholesale, retail, professional services and administration sectors.

construction and demolition waste means legacy waste generated from construction and demolition activities both on a large scale and small scale.

degradable organic carbon content has the meaning given in the NGER (Measurement) Determination.

Greenhouse Friendly TM initiative means the program known by that name and administered by the Commonwealth Government.

legacy waste means waste physically accepted onto the premises of a waste diversion facility before 1 July 2012 that would otherwise have entered landfill.

NATA means the National Association of Testing Authorities, Australia (ACN 004 379 748).

National Measurement Act means the National Measurement Act 1960 as in force from time to time.

NGER (Measurement) Determination means the National Greenhouse and Energy Reporting (Measurement) Determination 2008 as in force from time to time.

NGER Regulations means the National Greenhouse and Energy Reporting Regulations 2008 as in force from time to time.

process engineered fuel means a fuel that is manufactured from waste to end‑user specifications and involves a number of process stages to convert waste into a quality assured and fit‐for‐use product.

project period means the period of time from 1 July 2010 to 1 July 2012 in which the diversion of legacy waste was undertaken.

residual waste means the material that remains at the end of processing by the waste diversion facility that is not a recycled product.

restricted waste type means waste that is the subject of a restriction in accordance with a licence or other authorisation relating to the waste diversion facility.

Survey of Motor Vehicle Use means the ‘Survey of Motor Vehicle Use, Australia, 12 months ended 31 October 2010’ published by the Australian Bureau of Statistics, which is available at http://www.abs.gov.au/ausstats/abs@.nsf/mf/9208.0

thermal oxidation means the process of combusting the process engineered fuel by the end user.

transitioning Greenhouse FriendlyTM project means a project that was previously approved as an abatement provider under the Greenhouse FriendlyTM initiative.

unrestricted waste type means waste that is not a restricted waste type.

waste diversion facility means a purpose built facility that is used to process commercial and industrial waste and construction and demolition waste that would otherwise have entered a landfill into a variety of products, including process engineered fuel.

Note: Several other words and expressions used in this Methodology Determination have the meaning given by section 5 of the Act, for example:

baseline;

carbon dioxide equivalence;

eligible offsets project;

emission;

greenhouse gas;

offsets project;

offsets report;

project proponent; and

reporting period.

(1) For paragraph 106 (1) (b) of the Act, this section sets out requirements that must be met for an offsets project to which this Methodology Determination applies to be an eligible offsets project.

(2) The offsets project must consist of diverting legacy waste to a waste diversion facility in circumstances where:

(a) the waste would otherwise have entered a landfill facility; and

(b) the waste is one or both of the following:

(i) commercial and industrial waste;

(ii) construction and demolition waste; and

(c) the waste mentioned in paragraph 2.1 (2) (b) is processed to produce process engineered fuel; and

(d) the process engineered fuel will undergo thermal oxidation for energy recovery purposes.

(3) The offsets project must relate to the diversion of legacy waste only.

(4) The waste diversion facility must have previously been approved as an abatement provider under the Greenhouse Friendly TM initiative.

Division 3.1 Preliminary

(1) In this Part:

(a) all calculations are in respect of activities that have been undertaken during the project period;

(b) a reference to a schedule means a reference to a schedule to this Methodology Determination;

(c) unless otherwise specified, a reference to a project is a reference to an offsets project to which this Methodology Determination applies;

(d) a reference to process engineered fuel means a reference to the process engineered fuel manufactured by the waste diversion facility, as a result of the offsets project; and

(e) a reference to an equation means a reference to an equation in this Methodology Determination.

(2) The data used in the calculations set out in Division 3.2 must comply with the data collection requirements set out in Division 3.3 of this Methodology Determination.

(3) If a calculation in Division 3.2 refers to a factor or parameter that is not otherwise specified in Schedules 1 to 5 of this Methodology Determination, the person carrying out the calculations must apply the factor or parameter prescribed in the NGER (Measurement) Determination or the NGER Regulations in force at the time that the offsets report was required to be submitted.

3.2 Greenhouse gas assessment boundary

(1) The following greenhouse gases from the following activities must be taken into account when making calculations under this Part in respect of each of the following kinds of activities within the project. No other gases may be taken into account.

Table of gases accounted for in the abatement calculations

| Project activity | Greenhouse gas |

| Estimated decomposition of legacy waste at a landfill site | Methane (CH4) |

|

|

| On-site fossil fuel consumption other than for electricity generation for process engineered fuel manufacture | Carbon dioxide (CO2) |

| Methane (CH4) |

| Nitrous oxide (N2O) |

| Emissions from transport of process engineered fuel Note: These emissions are included subject to subsection 3.2 (2) of this Methodology Determination. | Carbon dioxide (CO2) |

| Methane (CH4) |

| Nitrous oxide (N2O) |

| Emissions from transport of residual waste to landfill Note: These emissions are included subject to subsection 3.2 (2) of this Methodology Determination. | Carbon dioxide (CO2) |

| Methane (CH4) |

| Nitrous oxide (N2O) |

Emissions from transport

(2) Emissions from the transport of process engineered fuel and residual waste must only be included in calculations under this Part if the destination is outside a radius of 10 kilometres from the waste diversion facility.

Note: This is calculated using Equation 8.

3.3 Calculating the baseline for the offsets project

For paragraph 106 (4) (f) of the Act, the baseline for a project is the methane that would have been emitted if the waste specified in paragraph 2.1 (2) (b) of this Methodology Determination had entered landfill. The baseline is calculated in accordance with Division 3.2 of this Methodology Determination.

Division 3.2 Calculations

3.4 Calculating baseline emissions (Eb)

(1) For the purposes of paragraph 106 (4) (f) of the Act, the baseline for the project is calculated as follows:

| Equation 1 |

Where:

Eb = baseline emissions, measured in tonnes of CO2-e.

Lo = methane generation potential of the degradable organic carbon content in the process engineered fuel, measured in tonnes of CH4 and calculated in accordance with Equation 2.

OF = oxidation factor for near surface methane in landfill as prescribed in Schedule 3.

GWPCH4 = global warming potential conversion factor for tonnes of CH4 into tonnes CO2-e, as prescribed in Schedule 3.

R = percentage of landfill gas that would have been captured and thermally oxidised, as prescribed in Schedule 4.

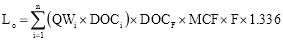

(2) Lo is calculated as follows:

| Equation 2 |

Where:

Lo = methane generation potential of the degradable organic carbon content in the process engineered fuel, measured in tonnes of CH4.

QWi = quantity of waste mix type i present in the process engineered fuel, measured in tonnes, and calculated in accordance with Equation 3.

DOCi = degradable organic carbon value of waste mix type i, as prescribed in Schedule 1.

DOCF = fraction of degradable organic carbon dissimilated, as prescribed in Schedule 1.

MCF = 1, the methane correction factor for aerobic decomposition.

F = 0.5, the fraction by volume of methane in landfill gas.

Note: Waste mix types (i), degradable organic carbon value (DOCi) and degradable organic carbon (DOCF) values are set out in Schedule 1.

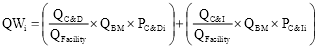

(3) QWi is calculated as follows:

| Equation 3 |

Where:

QWi= quantity of waste mix type i present in the process engineered fuel, measured in tonnes.

QC&D = quantity of legacy waste from construction and demolition sources received by the waste diversion facility, measured in tonnes.

QC&I = quantity of legacy waste from commercial and industrial sources received by the waste diversion facility, measured in tonnes.

QFacility = quantity of legacy waste received by the waste diversion facility, measured in tonnes.

QBM = quantity of biobased legacy waste material containing degradable organic carbon present in the process engineered fuel, measured in tonnes and calculated in accordance with Equation 5.

PC&Di = percentage of waste mix type i in the biobased legacy waste material from construction and demolition sources, based on the proportions of waste mix type for construction and demolition waste, calculated in accordance with Schedule 2.

PC&Ii = percentage of waste mix type i in the biobased legacy waste material from commercial and industrial sources, based on the proportions of waste mix type for commercial and industrial waste, calculated in accordance with Schedule 2.

Note 1: Prescribed waste material types (i) are set out in Schedule 1. The percentage of waste mix type values for construction and demolition and commercial and industrial waste types are set out in Schedule 2.

Note 2: Equation 4 is set out in Schedule 2.

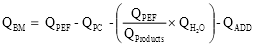

3.5 Calculating the quantity of biobased legacy waste material containing degradable organic carbon (QBM)

(1) For the purpose of this section:

(a) QPEF must include process engineered fuel inventory at the start of the project period and at the end of the project period, and material accepted onto the facility for process engineered fuel manufacture during the project period, that is yet to be processed.

(b) QH2O must be adjusted for evaporation and losses on a mass balance reconciliation of input tonnes, stock inventory and output tonnes for the project facility over the project period with evaporation and losses as the balancing item in accordance with Schedule 5.

(2) QBM is calculated as follows:

| Equation 5 |

Where:

QBM = quantity of biobased legacy waste material containing degradable organic carbon present in the process engineered fuel, measured in tonnes.

QPEF = quantity of process engineered fuel, measured in tonnes.

QPC = the quantity of plastic within the process engineered fuel, measured in tonnes, calculated using the PEF protocol as set out in Section 3.12 of this Methodology Determination and multiplying the estimated proportion by QPEF.

QProducts = quantity of all product types produced in the manufacture of process engineered fuel for the project period, and measured in tonnes.

QH2O = the quantity of water retained in product types, calculated in accordance with Schedule 5.

QADD = the quantity of additives within the process engineered fuel, that are additional to the biobased legacy waste material types diverted from landfill, measured in tonnes.

Subdivision 3.2.2 Calculating project emissions

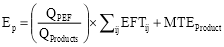

3.6 Project emissions (Ep)

(1) EP is calculated as follows:

| Equation 6 |

Where:

Ep = emissions from the project, measured in tonnes of CO2-e.

QPEF = quantity of process engineered fuel, measured in tonnes.

QProducts = quantity of all product types produced in the manufacture of process engineered fuel, measured in tonnes.

EFTij = emissions of gas type j, being carbon dioxide, methane or nitrous oxide, released from the combustion of fuel type i from the operation of the facility to manufacture processed engineered fuel, measured in tonnes of CO2-e and calculated in accordance with Equation 7.

MTEProduct = material transport emissions associated with all product types, measured in tonnes of CO2-e and calculated in accordance with Equation 8.

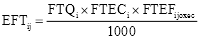

(2) EFTij is calculated as follows:

| Equation 7 |

Where:

EFTij = emissions of gas type j, being carbon dioxide, methane or nitrous oxide, released from the combustion of fuel type i from the operation of the facility to manufacture process engineered fuel, measured in tonnes of CO2-e.

FTQi = quantity of fuel type i measured in tonnes, cubic metres or kilolitres (for solid, gas and liquid fuels respectively), used in the operation of the facility to manufacture process engineered fuel.

FTECi = energy content factor of fuel type i as prescribed in the NGER (Measurement) Determination, and measured in gigajoules per tonne, cubic metre or kilolitre.

FTEFijoxec = emission factor for each gas type j released from the combustion of fuel type i, measured in kilograms of CO2-e per gigajoule of fuel type i, calculated using the relevant emission factor prescribed in Schedule 1 of the NGER (Measurement) Determination.

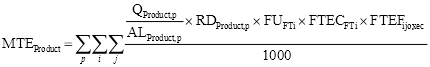

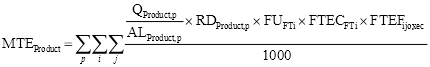

3.7 Calculating emissions from transport (MTEProduct)

(1) Where the transport destination for the process engineered fuel and residual waste is outside a radius of 10 kilometres in distance from the waste diversion facility, then (MTEProduct) must be calculated as follows:

| Equation 8 |

Where:

MTEProduct = material transport emissions associated with all product types, measured in tonnes of CO2-e.

QProduct,p = quantity of product type p, measured in tonnes.

ALProduct,p = average load weight for each load of product type p that is transported from the waste diversion facility, measured in tonnes.

RDProduct,p = return distance trip from the waste diversion facility, measured using a publicly available internet mapping tool, and rounded to the nearest kilometre.

FUFTi = 5.62 10-4, fuel usage factor for fuel type i- n, measured in kilolitres per kilometre.

10-4, fuel usage factor for fuel type i- n, measured in kilolitres per kilometre.

FTECFTi = energy content factor of fuel type i as prescribed in Schedule 1 of the NGER (Measurement) Determination, measured in gigajoules per cubic metre for gas or per kilolitre for liquid fuels.

FTEFijoxec = the emission factor for each gas type j released from the combustion of fuel type i, measured in kilograms of CO2-e per gigajoule of fuel type i, as prescribed in Schedule 1 of the NGER (Measurement) Determination.

Subdivision 3.2.3 Calculating carbon dioxide equivalent net abatement amount

3.8 Calculating carbon dioxide equivalent net greenhouse gas abatement for the project (A)

(1) The carbon dioxide equivalent net abatement amount for an offsets project to which this Methodology Determination applies must be calculated as follows:

Where:

A = carbon dioxide equivalent net greenhouse gas abatement, measured in tonnes of CO2-e.

Eb = baseline emissions, measured in tonnes of CO2-e, calculated in accordance with Equation 1.

EP = project emissions measured in tonnes of CO2-e, calculated in accordance with Equation 6.

(2) For paragraph 106 (1) (c) of the Act, the carbon dioxide equivalent net abatement amount for an offsets project in relation to the reporting period must be calculated as follows:

Where:

Areport = net carbon dioxide equivalent greenhouse gas abatement for the reporting period, measured in tonnes of CO2-e.

A = carbon dioxide equivalent net greenhouse gas abatement, measured in tonnes of CO2-e, calculated in accordance with Equation 9.

Y = number of years in reporting period.

Note: The sum of the number of years in each reporting period for all reports submitted must not be greater than 7.

Division 3.3 Data Collection

The project proponent of an offsets project to which this Methodology Determination applies must comply with the data collection requirements contained in this Division.

3.10 Data collection procedures and measurement frequency

A project proponent must measure the matters specified in the following table, in the manner and frequency specified, for the purposes of calculating baseline emissions and project emissions.

Parameter | Description | Unit | Measurement Procedure | Measurement Frequency |

QFacility | Quantity of legacy waste accepted into project facility. | Tonnes (t) | Weighbridge protocol Note: See section 3.11 | Per load and then summed for project period. |

QPEF | Quantity of process engineered fuel delivered to end users. | Tonnes (t) | Weighbridge protocol Note: See section 3.11 | Per load and then summed for project period. |

QProducts | Quantity of all product types produced in the manufacture of process engineered fuel (including process engineered fuel). | Tonnes (t) | Weighbridge protocol Note: See section 3.11 | Per load and then summed for project period. |

PEF product quality | | Mass percentage (%) | Quality sampling protocol Note: See section 3.12 | Weekly or as required for representative sample. |

Water | Water usage in project facility. | Kilolitres (kL) | Invoice and internal records for non mains water supply. | Six monthly (or as invoiced). |

QC&D | Quantity of legacy waste received by the facility from construction and demolition sources. | Tonnes (t) | Weighbridge protocol. Note: See section 3.11 | Per load and then summed for project period. |

QC&I | Quantity of legacy waste received by the facility from commercial and industrial sources. | Tonnes (t) | Weighbridge protocol. Note: See section 3.11 | Per load and then summed for project period. |

QPC | Quantity of plastic within the process engineered fuel. | Tonnes (t) | Representative sampling to get the proportion of plastic in the process engineered fuel and multiplying by total PEF. Note: See section 3.12 | Project period. |

QH2O | Quantity of water retained in product types manufactured by the project facility. | Kilolitres (kL) | Measured using direct records and the PEF Protocol at Section 4.3 and in accordance with Schedule 5. | Project period. |

QADD | Quantity of additives within the process engineered fuel that are additional to the biobased legacy waste material types diverted from landfill, that exclude additional water. | Tonnes (t) | Measured using direct records such as invoices, or calculated using the PEF Protocol at Section 4.3 and multiplying the estimated proportion by QPEF. | Project period. |

FTQi | Quantity of fuel type (i), (whether solid, gas or liquid) used in the operation of the facility to manufacture process engineered fuel and other recovered resource by-products. | Measured in tonnes (t), cubic metres (m3) or kilolitres (kL) - for solid, gas and liquid fuels respectively | Invoiced amount of fuel usage, or as measured onsite use (for example, diesel from an onsite bowser). | Monthly, or as per invoice cycle, and summed for the project period. |

QProduct,p | Quantity of product type (p) produced by the facility. | Tonnes (t) | Weighbridge protocol. Note: See section 3.11 | Per load and then summed for project period. |

RDProduct,p | Return distance trip from the waste diversion facility. | Kilometres (km) | Measured in accordance with Equation 10. | Project period. |

ALProduct, p | Average load weight of a given product type (p). | Tonnes (t) | Weighbridge protocol, and summing the weight of all loads of product type (p) and then dividing by the number of loads of product type (p). Note: See section 3.11 | Project period. |

3.11 Using the weighbridge protocol

(1) A weighbridge must be used to collect and record the total tonnes of each of the following:

(a) incoming legacy waste materials;

(b) process engineered fuel sent to end user;

(c) other resources recovered;

(d) outgoing residual waste to landfill; and

(e) any loads rejected by the end user.

(2) Weighbridge records must be created and maintained for the following information for each load of legacy waste materials:

(a) vehicle registration;

(b) date and time received;

(c) weight of vehicle; and

(d) source of the material.

(3) The project proponent must collect data relating to calibration and testing of the weighbridge used in the project in accordance with section 4.4 of this Methodology Determination.

3.12 Using the quality sampling PEF protocol

Process engineered fuel must be sampled in accordance with the method set out in section 4.3 of this Methodology Determination.

Part 4 Monitoring, record-keeping and reporting requirements

Division 4.1 General

For the purposes of subsection 106 (3) of the Act, a project proponent of an offsets project to which this Methodology Determination applies must comply with the monitoring, record-keeping and reporting requirements contained in this Part.

(1) The project proponent must develop a project monitoring plan that includes the following information:

(a) information about the project including:

(i) a project description; and

(ii) where the proponent is an organisation, an organisational description;

(b) operational information about the project, including:

(i) variables in baseline emissions;

(ii) project parameters;

(iii) operations and activities requiring control to ensure abatement;

(iv) check of incoming loads;

(v) processing to recover value and meet product specifications;

(vi) identification of risks to abatement; and

(vii) control of risks to abatement;

(c) information that details the following:

(i) personnel training and required qualifications; and

(ii) personnel responsibilities for monitoring and measuring;

(d) information detailing preventative and corrective action including the following:

(i) procedures for corrective action; and

(ii) personnel responsible for investigating corrective action;

(e) information detailing the equipment used, the purpose of the equipment and calibration procedures;

(f) information with respect to project monitoring including the following:

(i) procedures for measuring and monitoring;

(ii) sampling practices;

(iii) quality control practices; and

(iv) statistical error;

(g) information detailing the project records required, the availability of those records and responsibility for maintaining records;

(h) information relating to project verification including :

(i) timing of verification;

(ii) the process of verification; and

(i) any other information relevant to the project.

4.3 Sampling of process engineered fuel

(1) Process engineered fuel must be sampled in accordance with the following procedure:

(a) Enough samples must be taken to produce a representative sample;

(b) The samples must be combined into a composite sample at least once per week; and

(c) The composite sample must be separated into two representative parts that are between 350g and 450g; and

(d) One part of the composite sample must be used to determine the plastic composition on a mass basis; and

(e) The other part of the composite sample must be used to determine the additive content in accordance with relevant Australian Standards or equivalent.

(2) Samples must be tested by a NATA accredited laboratory.

Note: An example of enough occasions would include a minimum of 30 tests during a project period.

Division 4.3 Quality assurance and quality control

Weighbridge scales must be calibrated and checked in accordance with the methods prescribed in the National Measurement Act.

(1) The project proponent must keep records of the following:

Project monitoring plan

(a) the project monitoring plan developed in accordance with section 4.2 of this Methodology Determination;

General information

(b) process flow description of the facility;

(c) changes in process configuration;

(d) inventory of mobile plant and equipment such as front end loaders and excavators;

(e) internal reports on process engineered fuel quality;

(f) records of delivery of consignments of process engineered fuel to end users;

(g) independent audit records and results;

(h) maintenance records relevant to the operation of the weighbridge;

(i) details of any quality assurance accreditation;

Monitoring Devices

(j) information about weighbridge calibration and testing;

Data – direct and indirect measurement

(k) all values and calculations used to calculate the carbon dioxide equivalent net greenhouse gas abatement amount;

(l) weighbridge records on incoming and outgoing materials;

(m) evidence of fuel use;

(n) evidence of other input use;

Water used to manufacture process engineered fuel

(o) records of mains water used at the project facility in kilolitres; and

(p) records of any other water use including bore water, according to measurement availability.

Division 4.5 Offsets report requirements

4.6 Report requirements

(1) The following information is required to be included in all offsets reports:

(a) carbon dioxide equivalent net abatement amount and number of years in the reporting period;

(b) number of years in any previous reporting periods (as applicable);

(c) independent audit report;

(d) total tonnes of legacy waste accepted into the facility;

(e) quantity of process engineered fuel manufactured from legacy waste delivered to end users;

(f) quantity of process engineered fuel thermally oxidised by end users;

(g) quantity of all product types produced in the manufacture of process engineered fuel (including process engineered fuel);

(h) all values and calculations used to calculate net greenhouse gas abatement;

(i) water usage in project facility;

(j) quantity in tonnes of biobased legacy waste material containing degradable organic carbon within the process engineered fuel;

(k) proportion of each waste material types containing degradable organic carbon within the process engineered fuel;

(l) quantity of waste type i present in the process engineered fuel manufactured from legacy waste materials diverted from landfill;

(m) quantity of fuel type i used in the operation of the facility to manufacture process engineered fuel and other recovered resource by-products;

(n) baseline emissions; and

(o) project emissions.

Schedule 1

Table 1:Waste mix types, degradable organic carbon content and DOCF values.

| For the period 1 July 2011 -1 July 2012 | For the period 1 July 2010 - 1 July 2011 |

Item | Waste mix type | Degradable Organic Carbon value (DOCi) | DOCF value | Degradable Organic Carbon value (DOCi) | DOCF value |

1 | Food | 0.15 | 0.84 | 0.15 | 0.5 |

2 | Paper and cardboard | 0.40 | 0.49 | 0.40 | 0.5 |

3 | Garden and green | 0.20 | 0.47 | 0.20 | 0.5 |

4 | Wood | 0.43 | 0.23 | 0.43 | 0.5 |

5 | Textiles | 0.24 | 0.50 | 0.24 | 0.5 |

6 | Sludge | 0.05 | 0.50 | 0.05 | 0.5 |

7 | Nappies | 0.24 | 0.50 | 0.24 | 0.5 |

8 | Rubber and Leather | 0.39 | 0.50 | 0.39 | 0.5 |

9 | Concrete, metal, plastic and glass | 0.00 | 0.00 | 0.00 | 0.5 |

Schedule 2

(1) For subsection 3.4 (3) of this Methodology Determination:

(a) inert waste, which includes concrete, metal, plastic and glass, must be treated as a restricted waste type; and

(b) the percentage of the total waste tonnage for each waste mix type i mentioned in column 2 of Table 2 of this Schedule must be estimated by using the default waste stream percentages in columns 3 and 4 for the item for each waste mix type.

Table 2: Percentage of waste mix type

Item | Waste Mix Type | Commercial and Industrial Waste Default (%) | Construction and Demolition Waste Default (%) |

1 | Food | 21.5% | 0.0% |

2 | Paper and paper board | 15.5% | 3.0% |

3 | Garden and park | 4.0% | 2.0% |

4 | Wood and wood waste | 12.5% | 6.0% |

5 | Textiles | 4.0% | 0.0% |

6 | Sludge | 1.5% | 0.0% |

7 | Nappies | 0.0% | 0.0% |

8 | Rubber and leather | 3.5% | 0.0% |

9 | Inert waste (including concrete, metal, plastic and glass) | 37.5% | 89.0% |

Note: Sourced from section 5.11 of the NGER (Measurement) Determination

(2) If the waste diversion facility receives a restricted waste mix type, the percentage of the total waste volume for each waste mix type mentioned in column 2 of Table 2 of this Schedule must be estimated:

(a) for a restricted waste mix type — by using the maximum permitted tonnage of the restricted waste mix type received at the waste diversion facility, as a percentage of the total waste received at the waste diversion facility; and

(b) for each waste mix type that is an unrestricted waste mix type — by adjusting the default percentages in columns 3 and 4 of Table 2 of this Schedule for each unrestricted waste mix type, in accordance with subsection (3) of this Schedule.

(3) The following calculation must be used to adjust the default percentages for each unrestricted waste mix type i:

| Equation 4 |

Where:

Wmtuadj = the adjusted percentage for each unrestricted waste mix type.

Wmtu = the default percentage for each unrestricted waste mix type in columns 3 and 4 of Table 2 in this Schedule .

Wmtr = the default percentage for each restricted waste mix type in columns 3 and 4 of Table 2 in this Schedule .

Wmtrmax = the maximum percentage for each restricted waste mix type.

Schedule 3

Table 3: Specified Factors or Parameters

Factor or Parameter | Description | Value |

| The oxidation factor for near surface methane in a landfill | 0.1 |

| The global warming potential of methane | 21 |

Schedule 4

Table 4: Average state or territory based landfill gas capture rates

State or Territory | Percentage capture rate value for R (Equation 1) |

ACT | 52% |

NSW | 26% |

NT | 27% |

QLD | 18% |

SA | 31% |

TAS | 37% |

VIC | 36% |

WA | 30% |

Schedule 5

The quantity of water retained in total outgoing products must be calculated as follows:

(1) Water retention in products from additional water usage at the project facility must be adjusted for evaporation and losses on the basis of a mass balance reconciliation of total water usage, waste inputs and stock, and material outputs;

(2) Total water usage must be measured using invoiced amount of water usage for mains water, and/or tanker volume multiplied by number of loads for bore water usage;

(3) Total incoming waste is calculated as the opening stock at the start of project period, plus incoming waste materials, less closing stock at the end of project period;

(4) The quantity of retained water must be calculated as the total outgoing products in tonnes, less the total incoming waste measured in tonnes; and

(5) The quantity of evaporation and losses is taken to equal the total water usage at the facility less the quantity of retained water.

Note 1: For total water usage, data must be collected on a monthly or invoice cycle time period.

Note 2: For the purposes of this calculation, units are in kilolitres, and 1 kilolitre weighs 1 tonne.