Chapter 1—General

Part 1.1—Preliminary

1.1 Name of Determination

This Determination is the National Greenhouse and Energy Reporting (Measurement) Determination 2008.

Division 1.1.1—Overview

1.3 Overview—general

(1) This determination is made under section 10 of the National Greenhouse and Energy Reporting Act 2007. It provides for the measurement of the following:

(a) greenhouse gas emissions arising from the operation of facilities;

(b) the production of energy arising from the operation of facilities;

(c) the consumption of energy arising from the operation of facilities.

Note: Facility has the meaning given by section 9 of the Act.

(2) This determination deals with scope 1 emissions and scope 2 emissions.

Note: Scope 1 emission and scope 2 emission have the meaning given by section 10 of the Act (also see, respectively, regulations 2.23 and 2.24 of the Regulations).

(3) There are 4 categories of scope 1 emissions dealt with in this Determination.

Note: This Determination does not deal with emissions released directly from land management.

(4) The categories of scope 1 emissions are:

(a) fuel combustion, which deals with emissions released from fuel combustion (see Chapter 2); and

(b) fugitive emissions from fuels, which deals with emissions mainly released from the extraction, production, processing and distribution of fossil fuels (see Chapter 3); and

(c) industrial processes emissions, which deals with emissions released from the consumption of carbonates and the use of fuels as feedstock or as carbon reductants, and the emission of synthetic gases in particular cases (see Chapter 4); and

(d) waste emissions, which deals with emissions mainly released from the decomposition of organic material in landfill or other facilities, or wastewater handling facilities (see Chapter 5).

(5) Each of the categories has various subcategories.

1.4 Overview—methods for measurement

(1) This Determination provides methods and criteria for the measurement of the matters mentioned in subsection 1.3(1).

(2) For scope 1 emissions or scope 2 emissions:

(a) method 1 (known as the default method) is derived from the National Greenhouse Accounts methods and is based on national average estimates; and

(b) method 2 is generally a facility specific method using industry practices for sampling and Australian or equivalent standards for analysis; and

(c) method 3 is generally the same as method 2 but is based on Australian or equivalent standards for both sampling and analysis; and

(d) method 4 provides for facility specific measurement of emissions by continuous or periodic emissions monitoring.

Note: Method 4, that applies as indicated by provisions of this Determination, is as set out in Part 1.3.

(3) Data points relevant to the implementation of particular methods are set out in column 3 of the tables in Schedule 4 as ‘matters to be identified’.

Note: Regulations 4.07(2), 4.10, 4.11, 4.13, 4.14, 4.15, 4.17 and 4.17B of the Regulations require these matters to be identified to be included in reports under the Act.

1.5 Overview—energy

Chapter 6 deals with the estimation of the production and consumption of energy.

1.6 Overview—scope 2 emissions

Chapter 7 deals with scope 2 emissions.

1.7 Overview—assessment of uncertainty

Chapter 8 deals with the assessment of uncertainty.

Division 1.1.2—Definitions and interpretation

1.8 Definitions

In this Determination:

2006 IPCC Guidelines means the 2006 IPCC Guidelines for National Greenhouse Gas Inventories published by the IPCC.

2021 API Compendium means the document entitled Compendium of Greenhouse Gas Emissions Methodologies for the Oil and Natural Gas Industry, published in November 2021 by the American Petroleum Institute.

Note: The 2021 API Compendium is available at www.api.org.

ACARP Guidelines means the document entitled Guidelines for the Implementation of NGER Method 2 or 3 for Open Cut Coal Mine Fugitive GHG Emissions Reporting (C20005), published by the Australian Coal Association Research Program in December 2011.

accredited laboratory means a laboratory accredited by the National Association of Testing Authorities or an equivalent member of the International Laboratory Accreditation Cooperation in accordance with AS ISO/IEC 17025:2005, and for the production of calibration gases, accredited to ISO Guide 34:2000.

Act means the National Greenhouse and Energy Reporting Act 2007.

active gas collection means a system of wells and pipes that collect landfill gas through the use of vacuums or pumps.

alternative waste treatment activity means an activity that:

(a) accepts and processes mixed waste using:

(i) mechanical processing; and

(ii) biological or thermal processing; and

(b) extracts recyclable materials from the mixed waste.

alternative waste treatment residue means the material that remains after waste has been processed and organic rich material has been removed by physical screening or sorting by an alternative waste treatment activity that produces compost, soil conditioners or mulch in accordance with:

(a) State or Territory legislation; or

(b) Australian Standard AS 4454:2012.

ANZSIC industry classification and code means an industry classification and code for that classification published in the Australian and New Zealand Standard Industrial Classification (ANZSIC), 2006.

APHA followed by a number means a method of that number issued by the American Public Health Association and, if a date is included, of that date.

API Compendium means the document entitled Compendium of Greenhouse Gas Emissions Methodologies for the Oil and Natural Gas Industry, published in August 2009 by the American Petroleum Institute.

Note: The API Compendium is available at www.api.org.

applicable State or Territory legislation, for an underground mine, means a law of a State or Territory in which the mine is located that relates to coal mining health and safety, including such a law that prescribes performance‑based objectives, as in force on 1 July 2008.

Note: Applicable State or Territory legislation includes:

Coal Mine Health and Safety Act 2002 (NSW) and the Coal Mine Health and Safety Regulation 2006 (NSW)

Coal Mining Safety and Health Act 1999 (Qld) and the Coal Mining Safety and Health Regulation 2001 (Qld).

appropriate standard, for a matter or circumstance, means an Australian standard or an equivalent international standard that is appropriate for the matter or circumstance.

appropriate unit of measurement, in relation to a fuel type, means:

(a) for solid fuels—tonnes; and

(b) for gaseous fuels—metres cubed or gigajoules, except for liquefied natural gas which is kilolitres; and

(c) for liquid fuels other than those mentioned in paragraph (d)—kilolitres; and

(d) for liquid fuels of one of the following kinds—tonnes:

(i) crude oil, plant condensate other natural gas liquids;

(ii) petroleum coke;

(iii) refinery gas and liquids;

(iv) refinery coke;

(v) bitumen:

(vi) waxes;

(vii) carbon black if used as petrochemical feedstock;

(viii) ethylene if used as a petrochemical feedstock;

(ix) petrochemical feedstock mentioned in item 57 of Schedule 1 to the Regulations.

AS or Australian standard followed by a number (for example, AS 4323.1—1995) means a standard of that number issued by Standards Australia Limited and, if a date is included, of that date.

ASTM followed by a number (for example, ASTM D6347/D6347M‑99) means a standard of that number issued by ASTM International and, if a date is included, of that date.

Australian legal unit of measurement has the meaning given by the National Measurement Act 1960.

base of the low gas zone means the part of the low gas zone worked out in accordance with section 3.25A.

basin means a geological basin named in the Australian Geological Provinces Database.

Note: The Australian Geological Provinces Database is available at www.ga.gov.au.

biodiesel has the meaning given by the Regulations.

biogenic carbon fuel means energy that is:

(a) derived from plant and animal material, such as wood from forests, residues from agriculture and forestry processes and industrial, human or animal wastes; and

(b) not embedded in the earth for example, like coal oil or natural gas.

biological treatment of solid waste:

(a) means an alternative waste treatment activity consisting of a composting or anaerobic digestion process in which organic matter in solid waste is broken down by microorganisms; but

(b) does not include solid waste disposal in a landfill.

Note: Chapter 5 (waste) deals with solid waste disposal in a landfill as well as the biological treatment of solid waste (whether at a landfill or at a facility elsewhere).

biomethane has the meaning given by the Regulations.

blended fuel means fuel that is a blend of fossil and biogenic carbon fuels.

briquette means an agglomerate formed by compacting a particulate material in a briquette press, with or without added binder material.

calibrated to a measurement requirement, for measuring equipment, means calibrated to a specific characteristic, for example a unit of weight, with the characteristic being traceable to:

(a) a measurement requirement provided for under the National Measurement Act 1960 or any instrument under that Act for that equipment; or

(b) a measurement requirement under an equivalent standard for that characteristic.

captured for enhanced oil recovery: a greenhouse gas is captured for enhanced oil recovery if it is captured and transferred to the holder of an enhanced oil recovery authority for injection into a geological formation, such as a natural reservoir, to further oil or gas production activities and is not captured for permanent storage.

captured for permanent storage, in relation to a greenhouse gas, has the meaning given by section 1.19A.

CEM or continuous emissions monitoring means continuous monitoring of emissions in accordance with Part 1.3.

CEN/TS followed by a number (for example, CEN/TS 15403) means a technical specification (TS) of that number issued by the European Committee for Standardization and, if a date is included, of that date.

city gate means a distribution hub where gas is reduced in pressure before it enters the lower pressure, smaller diameter, distribution pipeline network.

CO2‑e means carbon dioxide equivalence.

CO2 stimulation means using carbon dioxide as a fluid in well stimulation treatment which enhances oil and gas production or recovery by increasing the permeability of the formation.

coal seam methane has the same meaning as in the Regulations.

COD or chemical oxygen demand means the total material available for chemical oxidation (both biodegradable and non‑biodegradable) measured in tonnes.

compressed natural gas has the meaning given by the Regulations.

core sample means a cylindrical sample of the whole or part of a strata layer, or series of strata layers, obtained from drilling using a coring barrel with a diameter of between 50 mm and 2 000 mm.

crude oil has the meaning given by the Regulations.

crude oil transport means the transportation of marketable crude oil to heavy oil upgraders and refineries by means that include the following:

(a) pipelines;

(b) marine tankers;

(c) tank trucks;

(d) rail cars.

decommissioned underground mine has the meaning given by the Regulations.

detection agent has the same meaning as in the Offshore Petroleum and Greenhouse Gas Storage Act 2006.

documentary standard means a published standard that sets out specifications and procedures designed to ensure that a material or other thing is fit for purpose and consistently performs in the way it was intended by the manufacturer of the material or thing.

domain, of an open cut mine, means an area, volume or coal seam in which the variability of gas content and the variability of gas composition in the open cut mine have a consistent relationship with other geological, geophysical or spatial parameters located in the area, volume or coal seam.

dry wood has the meaning given by the Regulations.

efficiency method has the meaning given by subsection 2.70(2).

EN followed by a number (for example, EN 15403) means a standard of that number issued by the European Committee for Standardization and, if a date is included, of that date.

enclosed composting activity means a semi‑enclosed or enclosed alternative waste or composting technology where the composting process occurs within a reactor that:

(a) has hard walls or doors on all 4 sides; and

(b) sits on a floor; and

(c) has a permanent positive or negative aeration system.

energy content factor, for a fuel, means gigajoules of energy per unit of the fuel measured as gross calorific value.

enhanced oil recovery authority means a licence, lease or approval by or under a law of the Commonwealth, State or Territory which authorises the injection of one or more greenhouse gases into one or more geological formations, such as a natural reservoirs, to further oil or gas production activities.

equivalent leak detection standard, means a standard or documented approach that:

(a) has equivalent or higher integrity than the method outlined in USEPA Method 21—Determination of organic volatile compound leaks, as set out in Appendix A‑7 of Title 40, Part 60 of the Code of Federal Regulations, United States of America or optical gas imaging in accordance with paragraph 98.234(a)(1) of Title 40, Part 98 of the Code of Federal Regulations, United States of America; and

(b) has equivalent or higher sensitivity for detecting leaks than:

(i) 60 grams per hour in accordance with paragraph 98.234(a)(1) of Title 40, Part 98 of the Code of Federal Regulations, United States of America; or

(ii) 10,000 parts per million or greater in accordance with the method outlined in USEPA Method 21—Determination of organic volatile compound leaks, as set out in Appendix A‑7 of Title 40, Part 60 of the Code of Federal Regulations, United States of America.

estimator, of fugitive emissions from an open cut mine using method 2 under section 3.21 or method 3 under section 3.26, means:

(a) an individual who has the minimum qualifications of an estimator set out in the ACARP Guidelines; or

(b) individuals who jointly have those minimum qualifications.

extraction area, in relation to an open cut mine, is the area of the mine from which coal is extracted.

feedstock has the meaning given by the Regulations.

ferroalloy has the meaning given by subsection 4.69(2).

flaring means the combustion of fuel for a purpose other than producing energy.

Example: The combustion of methane for the purpose of complying with health, safety and environmental requirements.

fuel means a substance mentioned in column 2 of an item in Schedule 1 to the Regulations other than a substance mentioned in items 58 to 66.

fuel oil has the meaning given by the Regulations.

fugitive emissions means greenhouse gas emissions that are:

(a) released in connection with, or as a consequence of, the extraction, processing, storage or delivery of fossil fuel; and

(b) not released from the combustion of fuel for the production of useable heat or electricity.

gas bearing strata is coal and carbonaceous rock strata:

(a) located in an open cut mine; and

(b) that has a relative density of less than 1.95 g/cm3.

gaseous fuel means a fuel mentioned in column 2 of items 17 to 30 of Schedule 1 to the Regulations.

gas stream means the flow of gas subject to monitoring under Part 1.3.

gassy mine means an underground mine that has at least 0.1% methane in the mine’s return ventilation.

Global Warming Potential means, in relation to a greenhouse gas mentioned in column 2 of an item in the table in regulation 2.02 of the Regulations, the value mentioned in column 4 for that item.

GPA followed by a number means a standard of that number issued by the Gas Processors Association and, if a date is included, of that date.

green and air dried wood has the meaning given by the Regulations.

greenhouse gas stream means a stream consisting of a mixture of any or all of the following substances captured for injection into, and captured for permanent storage in, a geological formation:

(a) carbon dioxide, whether in a gaseous or liquid state;

(b) a greenhouse gas other than carbon dioxide, whether in a gaseous or liquid state;

(c) one or more incidental greenhouse gas‑related substances, whether in a gaseous or liquid state, that relate to either or both of the greenhouse gases mentioned in paragraph (a) and (b);

(d) a detection agent, whether in a gaseous or liquid state;

so long as:

(e) the mixture consists overwhelmingly of either or both of the greenhouse gases mentioned in paragraphs (a) and (b); and

(f) if the mixture includes a detection agent—the concentration of the detection agent in the mixture is not more than the concentration prescribed in relation to the detection agent for the purposes of subparagraph (vi) of paragraph (c) of the definition of greenhouse gas substance in section 7 of the Offshore Petroleum and Greenhouse Gas Storage Act 2006.

Note: A greenhouse gas is captured for permanent storage in a geological formation if the gas is captured by, or transferred to, the holder of a licence, lease or approval mentioned in section 1.19A, under a law mentioned in that section, for the purpose of being injected into a geological formation (however described) under the licence, lease or approval.

gross vehicle mass means the tare weight of the vehicle plus its maximum carrying capacity, excluding trailers.

GST group has the same meaning as in the Fuel Tax Act 2006.

GST joint venture has the same meaning as in the Fuel Tax Act 2006.

GWPmethane means the Global Warming Potential of methane.

heavy duty vehicle means a vehicle with a gross vehicle mass of more than 4.5 tonnes.

higher method has the meaning given by subsection 1.18(5).

hydrofluorocarbons has the meaning given by section 4.99.

ideal gas law means the state of a hypothetical ideal gas in which the amount of gas is determined by its pressure, volume and temperature.

IEC followed by a number (for example, IEC 17025:2005) means a standard of that number issued by the International Electrotechnical Commission and, if a date is included, of that date.

incidental, for an emission, has the meaning given by subregulation 4.27(5) of the Regulations.

incidental greenhouse gas‑related substance, in relation to a greenhouse gas that is captured from a particular source material, means:

(a) any substance that is incidentally derived from the source material; or

(b) any substance that is incidentally derived from the capture; or

(c) if the captured greenhouse gas, whether in a pure form or in a mixture with other substances, is transported—any substance that is incidentally derived from the transportation; or

(d) if the captured greenhouse gas, whether in a pure form or in a mixture with other substances, is injected into a part of a geological formation—any substance that is incidentally derived from the injection; or

(e) if the captured greenhouse gas, whether in a pure form or in a mixture with other substances, is stored in a part of a geological formation—any substance that is incidentally derived from the storage.

independent expert, in relation to an operator of a landfill, means a person who:

(a) is independent of the operator of the landfill; and

(b) has relevant expertise in estimating or monitoring landfill surface gas.

inert waste means waste materials that contain no more than a negligible volume of degradable organic carbon and includes the following waste:

(a) concrete;

(b) metal;

(c) plastic;

(d) glass;

(e) asbestos concrete;

(f) soil.

integrated metalworks has the meaning given by subsection 4.64(2).

invoice includes delivery record.

IPCC is short for Intergovernmental Panel on Climate Change established by the World Meteorological Organization and the United Nations Environment Programme.

ISO followed by a number (for example, ISO 10396:2007) means a standard of that number issued by the International Organization of Standardization and, if a date is included, of that date.

Leak Detection and Repair Program or LDAR program means a system of procedures used at a facility to monitor, locate and repair leaking components in order to minimize emissions.

leaker, in relation to a component subject to an LDAR program, means:

(a) if optical gas imaging is used, a leaker is detected at a sensitivity of 60 grams per hour in accordance with paragraph 98.234(a)(1) of Title 40, Part 98 of the Code of Federal Regulations, United States of America; and

(b) if the method outlined in USEPA Method 21—Determination of organic volatile compound leaks, as set out in Appendix A‑7 of Title 40, Part 60 of the Code of Federal Regulations, United States of America is used, a leaker is detected if 10,000 parts per million or greater is measured consistent with that method; and

(c) if an equivalent leak detection standard is used, a leaker is detected at the sensitivity set for that standard.

Note: Under the definition of equivalent leak detection standard, the sensitivity must be equivalent or higher than the approaches in paragraph (a) or (b).

legacy emissions has the same meaning as in the National Greenhouse and Energy Reporting (Safeguard Mechanism) Rule 2015.

legacy waste means waste deposited at a landfill before 1 July 2016.

light duty vehicle means a vehicle other than a heavy duty vehicle.

liquefied natural gas has the same meaning as in the Regulations.

liquefied natural gas station means the plant and equipment used in the natural gas liquefaction, storage and transfer of liquefied natural gas, and includes:

(a) all onshore or offshore equipment that receives natural gas, liquefies and stores liquefied natural gas, and transfers the liquefied natural gas to a transportation system; and

(b) equipment that receives imported or transported liquefied natural gas, stores liquefied natural gas, re‑gasifies liquefied natural gas, and delivers re‑gasified natural gas to a natural gas transmission or distribution system.

liquefied petroleum gas has the same meaning as in the Regulations.

liquid fuel means a fuel mentioned in column 2 of items 31 to 54 of Schedule 1 to the Regulations.

lower method has the meaning given by subsection 1.18(6).

low gas zone means the part of the gas bearing strata of an open cut mine:

(a) that is located immediately below the original surface of the mine and above the base of the low gas zone; and

(b) the area of which is worked out by working out the base of the low gas zone.

main electricity grid has the meaning given by subsection 7.2(4).

marketable crude oil includes:

(a) conventional crude oil; and

(b) heavy crude oil; and

(c) synthetic crude oil; and

(d) bitumen.

method means a method specified in this determination for estimating emissions released from the operation of a facility in relation to a source.

municipal materials has the meaning given by the Regulations.

municipal solid waste class I means waste from domestic premises, council collections and other municipal sources where:

(a) the collection of organic waste on a regular basis in a dedicated bin is not provided to residents of the municipality as a standard practice; or

(b) the collection of organic waste on a regular basis in a dedicated bin provided to residents of the municipality cannot be confirmed as standard practice.

municipal solid waste class II means waste from domestic premises, council collections and other municipal sources where a bin dedicated for garden waste is:

(a) provided to residents of the municipality as a standard practice; and

(b) collected on a regular basis.

N/A means not available.

National Greenhouse Accounts means the set of national greenhouse gas inventories, including the National Inventory Report 2005, submitted by the Australian government to meet its reporting commitments under the United Nations Framework Convention on Climate Change and the 1997 Kyoto Protocol to that Convention.

natural gas has the meaning given by the Regulations.

natural gas distribution means the transport of pipeline natural gas over a combination of natural gas distribution pipelines from a city gate to customer delivery points.

natural gas distribution pipelines mean pipelines for the conveyance of pipeline natural gas that:

(a) are identified as a distribution pipeline in an access arrangement applicable to the pipeline; or

(b) meet both of the following:

(i) have a maximum design pressure of 1,050 kPa or less; and

(ii) are not natural gas gathering and boosting pipelines.

natural gas gathering and boosting means the activity to collect unprocessed natural gas or coal seam methane from gas wellheads and to compress, dehydrate, sweeten, or transport the gas through natural gas gathering and boosting pipelines to a natural gas processing station, a natural gas transmission pipeline or a natural gas distribution pipeline.

natural gas gathering and boosting pipeline means a pipeline for the conveyance of gas that:

(a) contains unprocessed natural gas or coal seam methane; and

(b) pertains to the activity of natural gas gathering and boosting.

Note: Such pipelines can operates at high or low pressures

natural gas gathering and boosting station means one or more pieces of plant and equipment used in natural gas gathering and boosting at a single location that operates as a unit in the natural gas gathering and boosting activity. The plant and equipment may include any of the following:

(a) compressors;

(b) generators;

(c) dehydrators;

(d) storage vessels;

(e) acid gas removal units;

(f) engines;

(g) boilers;

(h) heaters;

(i) flares;

(j) separation and processing equipment;

(k) associated storage or measurement vessels;

(l) equipment on, or associated with, an enhanced oil recovery well pad using CO2 or gas injection.

Note: The single location that operates as a unit will generally be known as a facility, station or node for operational purposes. It is not expected that stations will be defined differently for operational purposes and emissions accounting purposes.

natural gas liquefaction, storage and transfer means the activity to collect and liquefy natural gas and to store and transfer liquefied natural gas to a transportation system.

natural gas liquids has the meaning given by the Regulations.

natural gas processing station means the plant and equipment used in the natural gas processing in a single location, and includes:

(a) liquids recovery plant and equipment where the separation of natural gas liquids or non‑methane gases from unprocessed natural gas or coal seam methane occurs; and

(b) liquids recovery plant and equipment where the separation of natural gas liquids into one or more component mixtures occur; and

(c) gas separation trains where the removal of acidic gases from unprocessed natural gas or coal seam methane occurs;

Note: The separation includes one or more of the following: forced extraction of natural gas liquids, sulphur and carbon dioxide removal, fractionation of natural gas liquids, or the capture of CO2 separated from unprocessed natural gas and coal seam methane streams.

natural gas processing means one or both of the following activities:

(a) the separation of natural gas liquids or non‑methane gases from unprocessed natural gas or coal seam methane;

(b) the separation of natural gas liquids into one or more component mixtures.

Note: The separation includes one or more of the following: forced extraction of natural gas liquids, sulphur and carbon dioxide removal, fractionation of natural gas liquids, or the capture of CO2 separated from natural gas streams.

natural gas production includes offshore natural gas production and onshore natural gas production.

natural gas storage means the activity to store unprocessed natural gas, coal seam methane or natural gas that has been transferred from its original location for the primary purpose of load balancing (the process of equalizing the receipt and delivery of natural gas).

natural gas storage station means the plant and equipment used in natural gas storage, and includes:

(a) subsurface storage, such as depleted gas or oil reservoirs that store gas; and

(b) the equipment to undertake natural gas underground storage processes and operations (including compression, dehydration and flow measurement, but excluding natural gas transmission pipelines); and

(c) all the wellheads connected to the compression units located at the station that inject and recover natural gas into and from the underground reservoirs.

natural gas transmission means transmission of natural gas or plant condensate through one or more natural gas transmission pipelines from a natural gas processing station or a natural gas gathering and boosting network to any of the following:

(a) a natural gas distribution network;

(b) another natural gas processing station;

(c) a liquefied natural gas station;

(d) a large industrial facility, such as a power station.

natural gas transmission pipeline means a pipeline for the conveyance of pipeline natural gas or plant condensate that:

(a) is licensed as a transmission pipeline under a Commonwealth, State or Territory law; and

(b) has a maximum design pressure exceeding 1,050 kPa; and

(c) is not a natural gas distribution pipeline or a natural gas gathering and boosting pipeline.

non‑gassy mine means an underground mine that has less than 0.1% methane in the mine’s return ventilation.

non‑legacy waste means waste deposited at a landfill on or after 1 July 2016.

offshore natural gas production means the activity to produce, extract, recover, lift, stabilise, separate or treat unprocessed natural gas, condensate or coal seam methane on offshore submerged lands, including well workovers.

offshore platform includes:

(a) any platform structure, affixed temporarily or permanently to offshore submerged lands, that houses plant and equipment to do either or both of the following:

(i) extract unprocessed natural gas and condensate from the ocean or lake floor;

(ii) transfers such unprocessed natural gas and condensate to storage, transport vessels, or onshore; and

(b) secondary platform structures connected to the platform structure via walkways, and

(c) storage tanks associated with the platform structure; and

(d) floating production and storage offloading equipment; and

(e) submerged wellhead production structures.

offshore platform (shallow water) means an offshore platform standing in less than 200 metres of water.

offshore platform (deep water) means an offshore platform standing in at least 200 metres of water.

oil or gas exploration and development means the activity to explore for oil and gas resources and test, appraise, drill, develop and complete wells for oil and gas resources and includes the following actions:

(a) oil well drilling;

(b) gas well drilling;

(c) drill stem testing;

(e) well appraisals;

(f) development drilling;

(g) well completions;

(h) well workovers associated with the actions in the paragraphs above.

onshore natural gas production means the activity to produce, extract, recover, lift, stabilise, separate or treat unprocessed natural gas, condensate or coal seam methane on land, including well workovers.

onshore natural gas wellhead means the gas wellhead.

open cut mine:

(a) means a mine in which the overburden is removed from coal seams to allow coal extraction by mining that is not underground mining; and

(b) for method 2 in section 3.21 or method 3 in section 3.26—includes a mine of the kind mentioned in paragraph (a):

(i) for which an area has been established but coal production has not commenced; or

(ii) in which coal production has commenced.

PEM or periodic emissions monitoring means periodic monitoring of emissions in accordance with Part 1.3.

Perfluorocarbon protocol means the Protocol for Measurement of Tetrafluoromethane (CF4) and Hexafluoroethane (C2F6) Emissions from Primary Aluminium Production published by the United States Environmental Protection Agency and the International Aluminium Institute.

petroleum based greases has the meaning given by regulation 1.03 of the Regulations.

petroleum based oils has the meaning given by the Regulations.

petroleum coke has the meaning given by the Regulations.

phytocap means an evapotranspiration landfill capping system that makes use of soil and vegetation to store and release surface water.

pipeline natural gas means natural gas that is suitable for market consumption.

plant condensate has the meaning given by the Regulations.

post‑mining activities, in relation to a mine, is the handling, stockpiling, processing and transportation of coal extracted from the mine.

primary wastewater treatment plant:

(a) means a treatment facility at which wastewater undergoes physical screening, degritting and sedimentation; and

(b) does not include a treatment facility at which any kind of nitrification or denitrification treatment process occurs.

principal activity, in relation to a facility, means the activity that:

(a) results in the production of a product or service that is produced for sale on the market; and

(b) produces the most value for the facility out of any of the activities forming part of the facility.

produced water means the water that is either:

(a) pumped from coal seams or unprocessed gas reservoirs during natural gas production or natural gas gathering and boosting; or

(b) pumped from wells during crude oil production or oil and gas exploration and development.

pyrolysis of coal means the decomposition of coal by heat.

raw sugar has the meaning given by Chapter 17 of Section IV of Schedule 3 to the Customs Tariff Act 1995.

reductant:

(a) means a reducing agent or substance:

(i) that causes another substance to undergo reduction; and

(ii) that is oxidised while causing the substance to undergo reduction; and

(b) does not include fuels that are combusted only to produce energy.

refinery gases and liquids has the meaning given by the Regulations.

Regulations means the National Greenhouse and Energy Reporting Regulations 2008.

relevant person means a person mentioned in paragraph 1.19A(a), (b), (c), (d), (e) or (f).

renewable aviation kerosene has the meaning given by the Regulations.

renewable diesel has the meaning given by the Regulations.

run‑of‑mine coal means coal that is produced by mining operations before screening, crushing or preparation of the coal has occurred.

scope 1 emissions has the same meaning as in the Regulations.

scope 2 emissions has the same meaning as in the Regulations.

separate instance of a source has the meaning given by section 1.9A.

separate occurrence of a source has the meaning given by section 1.9B.

shale gas means a substance that:

(a) consists of:

(i) naturally occurring hydrocarbons; or

(ii) a naturally occurring mixture of hydrocarbons and non‑hydrocarbons; and

(b) consists mainly of methane; and

(c) is drained from shale formations.

shared infrastructure means fuel supply infrastructure from which fuel may be drawn by multiple facilities.

Note: for example, a Joint User Hydrant Installation.

shredder flock means the residual waste generated from the process of scrap metal processing that ends up in landfill.

sludge biogas has the meaning given by the Regulations.

sludge lagoon means a component of a wastewater treatment system that:

(a) is used to stabilise and dry excess or wasted sludge from the liquid or solid phase treatment train of a wastewater treatment plant; and

(b) involves biodegradation of COD in the form of sludge and the use of ambient climatic factors to reduce the moisture content of the sludge.

solid fuel means a fuel mentioned in column 2 of items 1 to 16 of Schedule 1 to the Regulations.

source has the meaning given by section 1.10.

specified taxable fuel has the meaning given by regulation 3.30 of the Clean Energy Regulations 2011.

standard includes a protocol, technical specification or USEPA method.

standard conditions has the meaning given by subsection 2.32(7).

sulphite lyes has the meaning given by the Regulations.

supply means supply by way of sale, exchange or gift.

synthetic gas generating activities has the meaning given by subsections 4.100(1) and (2).

tight gas means a substance that:

(a) consists of:

(i) naturally occurring hydrocarbons; or

(ii) a naturally occurring mixture of hydrocarbons and non‑hydrocarbons; and

(b) consists mainly of methane; and

(c) is drained from low permeability sandstone and limestone reservoirs.

uncertainty protocol means the publication known as the GHG protocol guidance on uncertainty assessment in GHG inventories and calculating statistical parameter uncertainty (September 2003) v1.0 issued by the World Resources Institute and the World Business Council for Sustainable Development.

underground mine means a coal mine that allows extraction of coal by mining at depth, after entry by shaft, adit or drift, without the removal of overburden.

USEPA followed by a reference to a method (for example, Method 3C) means a standard of that description issued by the United States Environmental Protection Agency.

waxes has the meaning given by the Regulations.

well completion means the period that:

(a) begins on the initial gas flow in the well; and

(b) ends on whichever of the following occurs first:

(i) well shut in; or

(ii) continuous gas flow from the well to a flow line or a storage vessel for collection.

well workover means activities performed to restore or increase production which can include any or all of the following processes:

(a) well venting;

(b) tubing maintenance;

(c) air clean out;

(d) hydraulic fracturing and recovery;

(e) well unloading.

wet weight, in relation to waste, is the weight of material that has not been treated to remove moisture.

year means a financial year.

Note: The following expressions in this Determination are defined in the Act:

carbon dioxide equivalence

consumption of energy (see also regulation 2.26 of the Regulations)

energy

facility

greenhouse gas

group

industry sector

operational control

potential greenhouse gas emissions

production of energy (see also regulation 2.25 of the Regulations)

registered corporation

scope 1 emission (see also regulation 2.23 of the Regulations)

scope 2 emission (see also regulation 2.24 of the Regulations).

1.9 Interpretation

(1) In this Determination, a reference to emissions is a reference to emissions of greenhouse gases.

(2) In this Determination, a reference to a gas type (j) is a reference to a greenhouse gas.

(3) In this Determination, a reference to a facility that is constituted by an activity is a reference to the facility being constituted in whole or in part by the activity.

Note: Section 9 of the Act defines a facility as an activity or series of activities.

(4) In this Determination, a reference to a standard, instrument or other writing (other than a Commonwealth Act or Regulations) however described, is a reference to that standard, instrument or other writing as in force on 1 January 2020.

1.9A Meaning of separate instance of a source

If 2 or more different activities of a facility have the same source of emissions, each activity is taken to be a separate instance of the source if the activity is performed by a class of equipment different from that used by another activity.

Example: The combustion of liquefied petroleum gas in the engines of distribution vehicles of the facility operator and the combustion of liquid petroleum fuel in lawn mowers at the facility, although the activities have the same source of emissions, are taken to be a separate instance of the source as the activities are different and the class of equipment used to perform the activities are different.

1.9B Meaning of separate occurrence of a source

(1) If 2 or more things at a facility have the same source of emissions, each thing may be treated as a separate occurrence of the source.

Example: The combustion of unprocessed natural gas in 2 or more gas flares at a facility may be treated as a separate occurrence of the source (natural gas production or processing—flaring).

(2) If a thing at a facility uses 2 or more energy types, each energy type may be treated as a separate occurrence of the source.

Example: The combustion of diesel and petrol in a vehicle at a facility may be treated as a separate occurrence of the source (fuel combustion).

1.10 Meaning of source

(1) A thing mentioned in the column headed ‘Source of emissions’ of the following table is a source.

Item | Category of source | Source of emissions |

1 | Fuel combustion | |

1A | | Fuel combustion |

2 | Fugitive emissions | |

2A | | Underground mines |

2B | | Open cut mines |

2C | | Decommissioned underground mines |

2D | | Oil or gas exploration and development—flaring |

2E | | Oil or gas exploration and development (other than flaring) |

2F | | Crude oil production |

2G | | Crude oil transport |

2H | | Crude oil refining |

2I | | Onshore natural gas production (other than emissions that are vented or flared) |

2J | | Offshore natural gas production (other than emissions that are vented or flared) |

2K | | Natural gas gathering and boosting (other than emissions that are vented or flared) |

2L | | Produced water from oil and gas exploration and development, crude oil production, natural gas production or natural gas gathering and boosting (other than emissions that are vented or flared) |

2M | | Natural gas processing (other than emissions that are vented or flared) |

2N | | Natural gas transmission (other than flaring) |

2O | | Natural gas storage (other than emissions that are vented or flared) |

2P | | Natural gas liquefaction, storage and transfer (other than emissions that are vented or flared) |

2Q | | Natural gas distribution (other than flaring) |

2R | | Onshore natural gas production—venting |

2S | | Offshore natural gas production—venting |

2T | | Onshore natural gas production—flaring |

2U | | Offshore natural gas production—flaring |

2V | | Natural gas gathering and boosting—venting |

2W | | Natural gas gathering and boosting—flaring |

2X | | Natural gas processing—venting |

2Y | | Natural gas processing—flaring |

2Z | | Natural gas transmission—flaring |

2ZA | | Natural gas storage—venting |

2ZB | | Natural gas storage—flaring |

2ZC | | Natural gas liquefaction, storage and transfer—venting |

2ZE | | Natural gas liquefaction, storage and transfer—flaring |

2ZF | | Natural gas distribution—flaring |

2ZG | | Carbon capture and storage |

2ZH | | Enhanced oil recovery |

3 | Industrial processes | |

3A | | Cement clinker production |

3B | | Lime production |

3C | | Use of carbonates for the production of a product other than cement clinker, lime or soda ash |

3D | | Soda ash use |

3E | | Soda ash production |

3F | | Ammonia production |

3G | | Nitric acid production |

3H | | Adipic acid production |

3I | | Carbide production |

3J | | Chemical or mineral production, other than carbide production, using a carbon reductant or carbon anode |

3JA | | Sodium cyanide production |

3JB | | Hydrogen production |

3K | | Iron, steel or other metal production using an integrated metalworks |

3L | | Ferroalloys production |

3M | | Aluminium production |

3N | | Other metals production |

3O | | Emissions of hydrofluorocarbons and sulphur hexafluoride gases |

4 | Waste | |

4A | | Solid waste disposal on land |

4AA | | Biological treatment of solid waste |

4B | | Wastewater handling (industrial) |

4C | | Wastewater handling (domestic or commercial) |

4D | | Waste incineration |

(2) The extent of the source is as provided for in this Determination.

Part 1.2—General

1.11 Purpose of Part

This Part provides for general matters as follows:

(a) Division 1.2.1 provides for the measurement of emissions and energy and also deals with standards;

(b) Division 1.2.2 provides for methods for measuring emissions;

(c) Division 1.2.3 provides requirements in relation to carbon capture and storage.

Division 1.2.1—Measurement and standards

1.12 Measurement of emissions and energy

(1) The measurement of emissions released from the operation of a facility is to be done by estimating the emissions in accordance with this Determination.

(2) The measurement of the production and consumption of energy from the operation of a facility is to be done by estimating the production and consumption of energy in accordance with this Determination.

1.13 General principles for measuring emissions and energy

Estimates for this Determination must be prepared in accordance with the following principles:

(a) transparency—emission and energy estimates must be documented and verifiable;

(b) comparability—emission and energy estimates using a particular method and produced by a registered corporation or registered person in an industry sector must be comparable with emission and energy estimates produced by similar corporations or persons in that industry sector using the same method and consistent with the emission and energy estimates published by the Department in the National Greenhouse Accounts;

(c) accuracy—having regard to the availability of reasonable resources by a registered corporation or registered person and the requirements of this Determination, uncertainties in emission and energy estimates must be minimised and any estimates must neither be over nor under estimates of the true values at a 95% confidence level;

(d) completeness—all identifiable emission sources mentioned in section 1.10 must be accounted for and production and consumption of all identifiable fuels and energy commodities listed in Schedule 1 of the Regulations must be accounted for, subject to any applicable reporting thresholds.

1.14 Assessment of uncertainty

The estimate of emissions released from the operation of a facility must include assessment of uncertainty in accordance with Chapter 8.

1.15 Units of measurement

(1) For this Determination, measurements of fuel must be converted as follows:

(a) for solid fuel, to tonnes; and

(b) for liquid fuels, to kilolitres unless otherwise specified; and

(c) for gaseous fuels, to cubic metres, corrected to standard conditions, unless otherwise specified.

(2) For this Determination, emissions of greenhouses gases must be estimated in CO2‑e tonnes.

(3) Measurements of energy content must be converted to gigajoules.

(4) The National Measurement Act 1960, and any instrument made under that Act, must be used for conversions required under this section.

1.16 Rounding of amounts

(1) If:

(a) an amount is worked out under this Determination; and

(b) the number is not a whole number;

then:

(c) the number is to be rounded up to the next whole number if the number at the first decimal place equals or exceeds 5; and

(d) rounded down to the next whole number if the number at the first decimal place is less than 5.

(2) Subsection (1) applies to amounts that are measures of emissions or energy.

1.17 Status of standards

If there is an inconsistency between this Determination and a documentary standard, this Determination prevails to the extent of the inconsistency.

Division 1.2.2—Methods

1.18 Method to be used for a separate occurrence of a source

(1) This section deals with the number of methods that may be used to estimate emissions of a particular greenhouse gas released, in relation to a separate occurrence of a source, from the operation of a facility.

(1A) Subsections (2) and (3) do not apply to a facility if:

(a) the principal activity of the facility is electricity generation (ANZSIC industry classification and code 2611) and the generating unit used to perform the principal activity:

(i) does not have the capacity to generate, in a reporting year, the amount of electricity mentioned in subparagraph 2.3(3)(b)(i); and

(ii) generates, in a reporting year, less than or equal to the amount of electricity mentioned in subparagraph 2.3(3)(b)(ii); or

(b) the principal activity of the facility is electricity generation (ANZSIC industry classification and code 2611) and the generating unit used to perform the principal activity:

(i) does not have the capacity to generate, in a reporting year, the amount of electricity mentioned in subparagraph 2.19(3)(b)(i); and

(ii) generates, in a reporting year, less than or equal to the amount of electricity mentioned in subparagraph 2.19(3)(b)(ii).

(2) Subject to subsection (3) and (3A), one method for the separate occurrence of a source must be used for 4 reporting years unless another higher method is used.

(3) If:

(a) at a particular time, a method is being used to estimate emissions in relation to the separate occurrence of a source; and

(b) either:

(i) in the preceding 4 reporting years before that time, only that method has been used to estimate the emissions from the separate occurrence of the source; or

(ii) a registered corporation or registered person certifies in writing that the method used was found to be non‑compliant during an external audit of the separate occurrence of the source;

then a lower method may be used to estimate emissions in relation to the separate occurrence of the source from that time.

(3A) If section 22AA of the Act applies to a person, a lower method may be used to estimate emissions in relation to the source for the purposes of reporting under section 22AA.

(4) In this section, reporting year, in relation to a source from the operation of a facility under the operational control of a registered corporation and entities that are members of the corporation’s group, means a year that the registered corporation is required to provide a report under section 19 of the Act in relation to the facility

(5) Higher method, is:

(a) a prescribed alternative method; or

(b) in relation to a method (the original method) being used to estimate emissions in relation to a separate occurrence of a source, a method for the source with a higher number than the number of the original method.

(6) Lower method, is:

(a) a default method; or

(b) in relation to a method (the original method) being used to estimate emissions in relation to a separate occurrence of a source, a method for the source with a lower number than the number of the original method.

1.18A Conditions—persons preparing report must use same method

(1) This section applies if a person is required, under section 19, 22A, 22AA, 22E, 22G or 22X of the Act (a reporting provision), to provide a report to the Regulator for a reporting year or part of a reporting year (the reporting period).

(2) For paragraph 10(3)(c) of the Act:

(a) the person must, before 31 August in the year immediately following the reporting year, notify any other person required, under a reporting provision, to provide a report to the Regulator for the same facility of the method the person will use in the report; and

(b) each person required to provide a report to the Regulator for the same facility and for the same reporting period must, before 31 October in the year immediately following the reporting year, take all reasonable steps to agree on a method to be used for each report provided to the Regulator for the facility and for the reporting period.

(3) If the persons mentioned in paragraph (2)(b) do not agree on a method before 31 October in the year immediately following the reporting year, each report provided to the Regulator for the facility and for the reporting period must use the method:

(a) that was used in a report provided to the Regulator for the facility for the previous reporting year (if any); and

(b) that will, of all the methods used in a report provided to the Regulator for the facility for the previous reporting year, result in a measurement of the largest amount of emissions for the facility for the reporting year.

(4) In this section, a reference to a method is a reference to a method or available alternative method, including the options (if any) included in the method or available alternative method.

Note 1: Reporting year has the meaning given by the Regulations.

Note 2: An example of available alternative methods is method 2 in section 2.5 and method 2 in section 2.6.

Note 3: An example of options included within a method is paragraphs 3.36(a) and (b), which provide 2 options of ways to measure the size of mine void volume.

Note 4: An example of options included within an available alternative method is the options for identifying the value of the oxidation factor (OFs) in subsection 2.5(3).

1.19 Temporary unavailability of method

(1) The procedure set out in this section applies if, during a reporting year, a method for a separate occurrence of a source cannot be used because of a mechanical or technical failure of equipment or a failure of measurement systems during a period (the down time).

(2) For each day or part of a day during the down time, the estimation of emissions from the separate occurrence of a source must be consistent with the principles in section 1.13.

(3) Subsection (2) only applies for a maximum of 6 weeks in a year. This period does not include down time taken for the calibration of the equipment.

(4) If down time is more than 6 weeks in a year, the registered corporation or registered person must inform the Regulator, in writing, of the following:

(a) the reason why down time is more than 6 weeks;

(b) how the corporation or person plans to minimise down time;

(c) how emissions have been estimated during the down time.

(5) The information mentioned in subsection (4) must be given to the Regulator within 6 weeks after the day when down time exceeds 6 weeks in a year.

(6) The Regulator may require a registered corporation or registered person to use method 1 to estimate emissions during the down time if:

(a) method 2, 3 or 4 has been used to estimate emissions for the separate occurrence of a source; and

(b) down time is more than 6 weeks in a year.

Division 1.2.3—Requirements in relation to carbon capture and storage

1.19A Meaning of captured for permanent storage

For this Determination, a greenhouse gas is captured for permanent storage only if it is captured by, or transferred to:

(a) the registered holder of a greenhouse gas injection licence under the Offshore Petroleum and Greenhouse Gas Storage Act 2006 for the purpose of being injected into an identified greenhouse gas storage formation under the licence in accordance with that Act; or

(b) the holder of an injection and monitoring licence under the Greenhouse Gas Geological Sequestration Act 2008 (Vic) for the purpose of being injected into an underground geological formation under the licence in accordance with that Act; or

(c) the registered holder of a greenhouse gas injection licence under the Offshore Petroleum and Greenhouse Gas Storage Act 2010 (Vic) for the purpose of being injected into an identified greenhouse gas storage formation under the licence in accordance with that Act; or

(d) the holder of a GHG injection and storage lease under the Greenhouse Gas Storage Act 2009 (Qld) for the purpose of being injected into a GHG stream storage site under the lease in accordance with that Act; or

(e) the holder of an approval under the Barrow Island Act 2003 (WA) for the purpose of being injected into an underground reservoir or other subsurface formation in accordance with that Act; or

(f) the holder of a gas storage licence under the Petroleum and Geothermal Energy Act 2000 (SA) for the purpose of being injected into a natural reservoir under the licence in accordance with that Act.

1.19B Deducting greenhouse gas that is captured for permanent storage

(1) If a provision of this Determination provides that an amount of a greenhouse gas that is captured for permanent storage may be deducted in the estimation of emissions under the provision, then the amount of the greenhouse gas may be deducted only if:

(a) the greenhouse gas that is captured for permanent storage is captured by, or transferred to, a relevant person; and

(b) the amount of the greenhouse gas that is captured for permanent storage is estimated in accordance with section 1.19E; and

(c) the relevant person issues a written certificate that complies with subsection (2).

(2) The certificate must specify:

(a) if the greenhouse gas is captured by the relevant person and is neither transferred to the relevant person nor transferred by the relevant person to another person—the following information:

(i) the amount of the greenhouse gas, measured in CO2‑e tonnes, captured by the relevant person;

(ii) the volume of the greenhouse gas stream containing the captured greenhouse gas;

(iii) the concentration of the greenhouse gas in the stream; or

(b) if the greenhouse gas is transferred to the relevant person—the following information:

(i) the amount of the greenhouse gas, measured in CO2‑e tonnes, that was transferred to the relevant person;

(ii) the volume of the greenhouse gas stream containing the transferred greenhouse gas;

(iii) the concentration of the greenhouse gas in the stream.

(3) The amount of the greenhouse gas that may be deducted is the amount specified in the certificate under paragraph (1)(c).

1.19C Capture from facility with multiple sources jointly generated

If, during the operation of a facility, more than 1 source generates a greenhouse gas, the total amount of the greenhouse gas that may be deducted in relation to the facility is to be attributed:

(a) if it is possible to determine the amount of the greenhouse gas that is captured for permanent storage from each source—to each source from which the greenhouse gas is captured according to the amount captured from the source; or

(b) if it is not possible to determine the amount of the greenhouse gas captured for permanent storage from each source—to the main source that generated the greenhouse gas that is captured during the operation of the facility.

1.19D Capture from a source where multiple fuels consumed

If more than 1 fuel is consumed for a source that generates a greenhouse gas that is captured for permanent storage, the total amount of the greenhouse gas that may be deducted in relation to the source is to be attributed to each fuel consumed in proportion to the carbon content of the fuel relative to the total carbon content of all fuel consumed for that source.

1.19E Measure of quantity of captured greenhouse gas

(1) For paragraph 1.19B(1)(b), the amount of a greenhouse gas that is captured must be estimated in accordance with this section.

(2) The volume of the greenhouse gas stream containing the captured greenhouse gas must be estimated:

(a) if the greenhouse gas stream is transferred to a relevant person—using:

(i) criterion A in section 1.19F; or

(ii) criterion AAA in section 1.19G; or

(b) if the greenhouse gas stream is captured by the relevant person and is neither transferred to the relevant person nor transferred by the relevant person to another person—using:

(i) criterion AAA in section 1.19G; or

(ii) criterion BBB in section 1.19GA.

(3) The greenhouse gas stream must be sampled in accordance with ISO 10715:1997, or an equivalent standard.

(4) The concentration of the greenhouse gas in the greenhouse gas stream must be analysed in accordance with the following parts of ISO 6974 or an equivalent standard:

(a) Part 1 (2000);

(b) Part 2 (2001);

(c) Part 3 (2000);

(d) Part 4 (2000);

(e) Part 5 (2000);

(f) Part 6 (2002).

(5) The volume of the greenhouse gas stream must be expressed in cubic metres.

(6) The greenhouse gas stream must be analysed for the concentration of the greenhouse gas on at least a monthly basis.

1.19F Volume of greenhouse gas stream—criterion A

(1) For subparagraph 1.19E(2)(a)(i), criterion A is the volume of the greenhouse gas stream that is:

(a) transferred to the relevant person during the year; and

(b) specified in a certificate issued by the relevant person under paragraph 1.19B(1)(c).

(2) The volume specified in the certificate must be accurate and must be evidenced by invoices issued by the relevant person.

1.19G Volume of greenhouse gas stream—criterion AAA

(1) For subparagraphs 1.19E(2)(a)(ii) and (b)(i), criterion AAA is the measurement during the year of the captured greenhouse gas stream from the operation of a facility at the point of capture.

(2) In measuring the quantity of the greenhouse gas stream at the point of capture, the quantity of the greenhouse gas stream must be measured:

(a) using volumetric measurement in accordance with:

(i) for a compressed greenhouse gas stream—section 1.19H; and

(ii) for a super‑compressed greenhouse gas stream—section 1.19I; and

(b) using gas measuring equipment that complies with section 1.19J.

(3) The measurement must be carried out using measuring equipment that:

(a) is in a category specified in column 2 of an item in the table in subsection (4) according to the maximum daily quantity of the greenhouse gas stream captured specified in column 3 for that item from the operation of the facility; and

(b) complies with the transmitter and accuracy requirements for that equipment specified in column 4 for that item, if the requirements are applicable to the measuring equipment being used.

(4) For subsection (3), the table is as follows.

Item | Gas measuring equipment category | Maximum daily quantity of greenhouse gas stream

(cubic metres/day) | Transmitter and accuracy requirements (% of range) |

1 | 1 | 0–50 000 | Pressure <±0.25% Diff. pressure <±0.25% Temperature <±0.50% |

2 | 2 | 50 001–100 000 | Pressure <±0.25% Diff. pressure <±0.25% Temperature <±0.50% |

3 | 3 | 100 001–500 000 | Smart transmitters: Pressure <±0.10% Diff. pressure <±0.10% Temperature <±0.25% |

4 | 4 | 500 001 or more | Smart transmitters: Pressure <±0.10% Diff. pressure <±0.10% Temperature <±0.25% |

1.19GA Volume of greenhouse gas stream—criterion BBB

For subparagraph 1.19E(2)(b)(ii), criterion BBB is the estimation of the volume of the captured greenhouse gas stream from the operation of the facility during a year measured in accordance with industry practice, if the equipment used to measure the volume of the captured greenhouse gas stream does not meet the requirements of criterion AAA.

Note: An estimate obtained using industry practice must be considered with the principles in section 1.13.

1.19H Volumetric measurement—compressed greenhouse gas stream

(1) For subparagraph 1.19G(2)(a)(i), volumetric measurement of a compressed greenhouse gas stream must be in cubic metres at standard conditions.

(1A) For this section and subparagraph 1.19G(2)(a)(i), a compressed greenhouse gas stream does not include either of the following:

(a) a super‑compressed greenhouse gas stream;

(b) a greenhouse gas stream that is compressed to a super‑critical state.

(2) The volumetric measurement is to be calculated using a flow computer that measures and analyses flow signals and relative density:

(a) if the greenhouse gas stream is captured by the relevant person and is neither transferred to the relevant person nor transferred by the relevant person to another person—at the point of capture of the greenhouse gas stream; or

(b) if the greenhouse gas stream is transferred to a relevant person—at the point of transfer of the greenhouse gas stream.

(3) The volumetric flow rate must be continuously recorded and integrated using an integration device that is isolated from the flow computer in such a way that if the computer fails, the integration device will retain the last reading, or the previously stored information, that was on the computer immediately before the failure.

(4) Subject to subsection (5), all measurements, calculations and procedures used in determining volume (except for any correction for deviation from the ideal gas law) must be made in accordance with the instructions contained in the following:

(a) for orifice plate measuring systems:

(i) the publication entitled AGA Report No. 3, Orifice Metering of Natural Gas and Other Related Hydrocarbon Fluids Part 3: Natural Gas Applications, published by the American Gas Association in August 1992; or

(ii) Parts 1 to 4 of the publication entitled ANSI/API MPMS Chapter 14.3 Part 2 (R2011) Natural Gas Fluids Measurement: Concentric, Square‑Edged Orifice Meters ‑ Part 2: Specification and Installation Requirements, 4th edition, published by the American Petroleum Institute on 30 April 2000;

(b) for turbine measuring systems—the publication entitled AGA Report No. 7, Measurement of Natural Gas by Turbine Meter (2006), published by the American Gas Association on 1 January 2006;

(c) for positive displacement measuring systems—the publication entitled ANSI B109.3—2000, Rotary Type Gas Displacement Meters, published by the American Gas Association on 13 April 2000.

(5) Measurements, calculations and procedures used in determining volume may also be made in accordance with an equivalent internationally recognised documentary standard or code.

(6) Measurements must comply with Australian legal units of measurement.

1.19I Volumetric measurement—super‑compressed greenhouse gas stream

(1) For subparagraph 1.19G(2)(a)(ii), volumetric measurement of a super‑compressed greenhouse gas stream must be in accordance with this section.

(2) If, in determining volume in relation to the super‑compressed greenhouse gas stream, it is necessary to correct for deviation from the ideal gas law, the correction must be determined using the relevant method contained in the publication entitled AGA Report No. 8, Compressibility Factor of Natural Gas and Related Hydrocarbon Gases (1994), published by the American Gas Association on 1 January 1994.

(3) The measuring equipment used must calculate super‑compressibility by:

(a) if the measuring equipment is category 3 or 4 equipment in accordance with column 2 the table in subsection 1.19G(4)—using composition data; or

(b) if the measuring equipment is category 1 or 2 equipment in accordance with column 2 of the table in subsection 1.19G(4)—using an alternative method set out in the publication entitled AGA Report No. 8, Compressibility Factor of Natural Gas and Related Hydrocarbon Gases (1994), published by the American Gas Association on 1 January 1994.

1.19J Gas measuring equipment—requirements

For paragraph 1.19G(2)(b), gas measuring equipment that is category 3 or 4 equipment in accordance with column 2 of the table in subsection 1.19G(4) must comply with the following requirements:

(a) if the equipment uses flow devices—the requirements relating to flow devices set out in section 1.19K;

(b) if the equipment uses flow computers—the requirement relating to flow computers set out in section 1.19L;

(c) if the equipment uses gas chromatographs—the requirements relating to gas chromatographs set out in section 1.19M.

1.19K Flow devices—requirements

(1) If the measuring equipment has flow devices that use orifice measuring systems, the flow devices must be constructed in a manner that ensures that the maximum uncertainty of the discharge coefficient is not greater than ±1.5%.

Note: The publication entitled AGA Report No. 3, Orifice Metering of Natural Gas and Other Related Hydrocarbon Fluids Part 3: Natural Gas Applications, published by the American Gas Association in August 1992, sets out a manner that ensures that the maximum uncertainty of the discharge coefficient is not greater than ±1.5%.

(2) If the measuring equipment has flow devices that use turbine measuring systems, the flow devices must be installed in a manner that ensures that the maximum uncertainty of the flow measurement is not greater than ±1.5%.

Note: The publication entitled AGA Report No. 8, Compressibility Factor of Natural Gas and Related Hydrocarbon Gases (1994), published by the American Gas Association on 1 January 1994, sets out a manner that ensures that the maximum uncertainty of the flow measurement is not greater than ±1.5%.

(3) If the measuring equipment has flow devices that use positive displacement measuring systems, the flow devices must be installed in a manner that ensures that the maximum uncertainty of flow is ±1.5%.

Note: The publication entitled ANSI B109.3—2000, Rotary Type Gas Displacement Meters, published by the American Gas Association on 13 April 2000, sets out a manner for installation that ensures that the maximum uncertainty of flow is ±1.5%.

(4) If the measuring equipment uses any other type of flow device, the maximum uncertainty of flow measurement must not be greater than ±1.5%.

(5) All flow devices that are used by measuring equipment of a category specified in column 2 of the table in subsection 1.19G(4) must, wherever possible, be calibrated for pressure, differential pressure and temperature in accordance with the requirements specified in column 4 for the category of equipment specified in column 2 for that item. The calibrations must take into account the effects of static pressure and ambient temperature.

1.19L Flow computers—requirements

For paragraph 1.19J(b), the requirement is that the flow computer that is used by the equipment for measuring purposes must record the instantaneous values for all primary measurement inputs and must also record the following outputs:

(a) instantaneous corrected volumetric flow;

(b) cumulative corrected volumetric flow;

(c) for turbine and positive displacement metering systems—instantaneous uncorrected volumetric flow;

(d) for turbine and positive displacement metering systems—cumulative uncorrected volumetric flow;

(e) super‑compressibility factor.

1.19M Gas chromatographs

For paragraph 1.19J(c), the requirements are that gas chromatographs used by the measuring equipment must:

(a) be factory tested and calibrated using a measurement standard produced by gravimetric methods and traceable to Australian legal units of measurement; and

(b) perform gas composition analysis with an accuracy of ±0.25% for calculation of relative density; and

(c) include a mechanism for re‑calibration against a certified reference gas.

Part 1.3—Method 4—Direct measurement of emissions

Division 1.3.1—Preliminary

1.20 Overview

(1) This Chapter provides for method 4 for a source.

Note: Method 4 as provided for in this Part applies to a source as indicated in the Chapter, Part, Division or Subdivision dealing with the source.

(2) Method 4 requires the direct measurement of emissions released from the source from the operation of a facility during a year by monitoring the gas stream at a site within part of the area (for example, a duct or stack) occupied for the operation of the facility.

(3) Method 4 consists of the following:

(a) method 4 (CEM) as specified in section 1.21 that requires the measurement of emissions using continuous emissions monitoring (CEM);

(b) method 4 (PEM) as specified in section 1.27 that requires the measurement of emissions using periodic emissions monitoring (PEM).

Division 1.3.2—Operation of method 4 (CEM)

Subdivision 1.3.2.1—Method 4 (CEM)

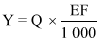

1.21 Method 4 (CEM)—estimation of emissions

(1) To obtain an estimate of the mass of emissions of a gas type (j), being methane, carbon dioxide or nitrous oxide, released at the time of measurement at a monitoring site within the area occupied for the operation of a facility, the following formula must be applied:

where:

Mjct is the mass of emissions in tonnes of gas type (j) released per second.

MMj is the molecular mass of gas type (j) measured in tonnes per kilomole which:

(a) for methane is 16.04 10‑3; or

10‑3; or

(b) for carbon dioxide is 44.01 10‑3; or

10‑3; or

(c) for nitrous oxide is 44.01 10‑3.

10‑3.

Pct is the pressure of the gas stream in kilopascals at the time of measurement.

FRct is the flow rate of the gas stream in cubic metres per second at the time of measurement.

Cjct is the proportion of gas type (j) in the volume of the gas stream at the time of measurement.

Tct is the temperature, in degrees kelvin, of the gas at the time of measurement.

(2) The mass of emissions estimated under subsection (1) must be converted into CO2‑e tonnes.

(3) Data on estimates of the mass emissions rates obtained under subsection (1) during an hour must be converted into a representative and unbiased estimate of mass emissions for that hour.

(4) The estimate of emissions of gas type (j) during a year is the sum of the estimates for each hour of the year worked out under subsection (3).

(5) If method 1 is available for the source, the total mass of emissions for a gas from the source for the year calculated under this section must be reconciled against an estimate for that gas from the facility for the same period calculated using method 1 for that source.

1.21A Emissions from a source where multiple fuels consumed

If more than one fuel is consumed for a source that generates carbon dioxide that is directly measured using method 4 (CEM), the total amount of carbon dioxide is to be attributed to each fuel consumed in proportion to the carbon content of the fuel relative to the total carbon content of all fuel consumed for that source.

Subdivision 1.3.2.2—Method 4 (CEM)—use of equipment

1.22 Overview

The following apply to the use of equipment for CEM:

(a) the requirements in section 1.23 about location of the sampling positions for the CEM equipment;

(b) the requirements in section 1.24 about measurement of volumetric flow rates in the gas stream;

(c) the requirements in section 1.25 about measurement of the concentrations of greenhouse gas in the gas stream;

(d) the requirements in section 1.26 about frequency of measurement.

1.23 Selection of sampling positions for CEM equipment

For paragraph 1.22(a), the location of sampling positions for the CEM equipment in relation to the gas stream must be selected in accordance with an appropriate standard.

Note: Appropriate standards include:

- AS 4323.1—1995 Stationary source emissions ‑ Selection of sampling positions.

- AS 4323[1].1—1995 Amdt 1‑1995 Stationary source emissions ‑ Selection of sampling positions.

- ISO 10396:2007 Stationary source emissions ‑ Sampling for the automated determination of gas emission concentrations for permanently‑installed monitoring systems.

- ISO 10012:2003 Measurement management systems ‑ Requirements for measurement processes and measuring equipment.

- USEPA – Method 1 – Sample and Velocity Traverses for Stationary Sources (2000).

1.24 Measurement of flow rates by CEM

For paragraph 1.22(b), the measurement of the volumetric flow rates by CEM of the gas stream must be undertaken in accordance with an appropriate standard.

Note: Appropriate standards include:

- ISO 10780:1994 Stationary source emissions—Measurement of velocity and volume flowrate of gas streams in ducts.

- ISO 14164:1999 Stationary source emissions—Determination of the volume flowrate of gas streams in ducts ‑ Automated method.

- USEPA Method 2 Determination of Stack Gas Velocity and Volumetric flowrate (Type S Pitot tube) (2000).

- USEPA Method 2A Direct Measurement of Gas Volume Through Pipes and Small Ducts (2000).

1.25 Measurement of gas concentrations by CEM

For paragraph 1.22(c), the measurement of the concentrations of gas in the gas stream by CEM must be undertaken in accordance with an appropriate standard.

Note: Appropriate standards include:

- USEPA Method 3A Determination of oxygen and carbon dioxide concentrations in emissions from stationary sources (instrumental analyzer procedure) (2006).

- USEPA Method 3C Determination of carbon dioxide, methane, nitrogen, and oxygen from stationary sources (1996).

- ISO 12039:2001 Stationary source emissions—Determination of carbon monoxide, carbon dioxide and oxygen—Performance characteristics and calibration of automated measuring system.

1.26 Frequency of measurement by CEM

(1) For paragraph 1.22(d), measurements by CEM must be taken frequently enough to produce data that is representative and unbiased.