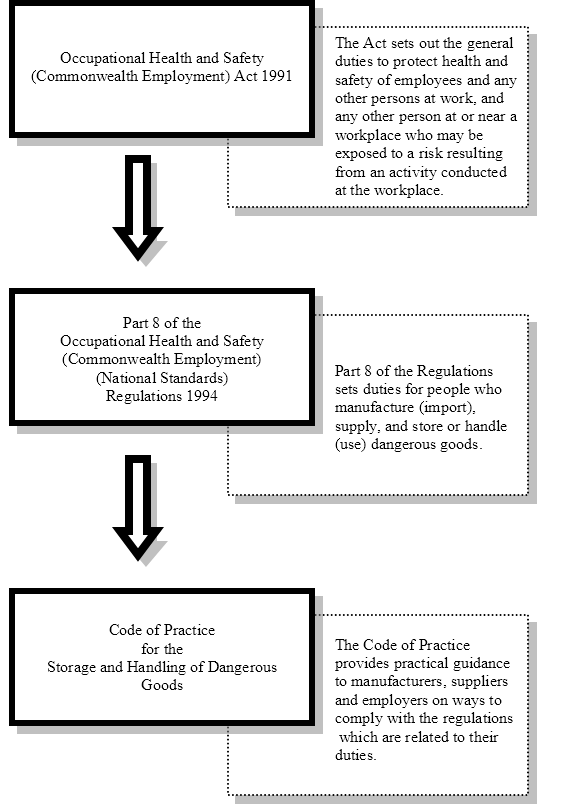

1.1 Part 8 of the Occupational Health and Safety (Commonwealth Employment) (National Standards) Regulations 1994 (the regulations) outlines the specific duties of manufacturers, suppliers, employers, and operators of pipelines in relation to the manufacture, supply, storage and handling of dangerous goods in the workplace.

1.2 The regulations are designed to ensure that workplaces, which store and handle significant amounts of dangerous goods, assess and manage all identified risks and hazards by controlling them through work practices such as training, correct labelling and implementing effective emergency plans and procedures.

1.3 This approved code of practice should be read in conjunction with the regulations.

1.4 Dangerous goods are those substances that may be hazardous to people, property or the environment, and may cause accidents with disastrous consequences. Dangerous goods may be corrosive, flammable, explosive, oxidising or reactive with water.

1.5 Regulation 8.04(3) defines dangerous goods as goods that:

(a) are named in column 2 of Appendix 2 to the ADG Code; or

(b) meet the criteria in Chapter 2 of the ADG Code; or

(c) are determined by a relevant Competent Authority to be dangerous goods; or

(d) are C1 combustible liquids; or

(e) are C2 combustible liquids, if stored and handled with fire risk dangerous

goods (within the meaning of sub regulation (4)); or

(f) are goods too dangerous to be transported.

1.6 In many cases, dangerous goods are confused with hazardous substances. Dangerous goods are classified according to their immediate physical or chemical hazards, such as fire, explosion, corrosion and toxicity that may affect life, health, property or the environment. Hazardous substances are classified only based on immediate or long-term health effects.

1.7 Dangerous goods and hazardous substances are covered by separate parts of the regulations to control the different risks involved. Part 6 of the regulations covers hazardous substances whilst Part 8 covers dangerous goods.

1.8 Many hazardous substances are also classified as dangerous goods, therefore, employers are required to comply with both sets of regulations.

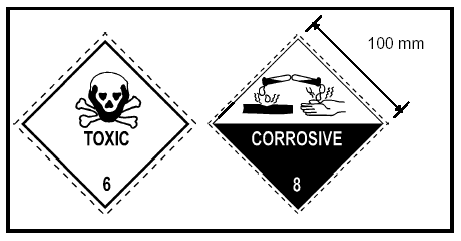

1.9 Regulation 8.05 outlines the different classes of dangerous goods. Table 1 below summarises the dangerous goods covered by the regulations and therefore, this code.

Table 1 Classes of dangerous goods

Classes of Goods | Description | Reference |

Dangerous goods: Class 2 Class 2.1 Class 2.2 Class 2.3 Class 3 Class 4 Class 4.1 Class 4.2 Class 4.3 Class 5 Class 5.1 Class 5.2 Class 6 Class 6.1 Class 8 Class 9 | Gases Flammable gas Non-flammable, non-toxic gases Toxic gases Flammable liquids Flammable solids, etc. Flammable solids, self-reactive, desensitised Substances liable to spontaneous combustion Substances in contact with water emit flammable gases Oxidizing substances; organic peroxides Oxidizing substances Organics peroxides Toxic and infectious substances Toxic substances Corrosive substances Miscellaneous substances and articles | ADG Code |

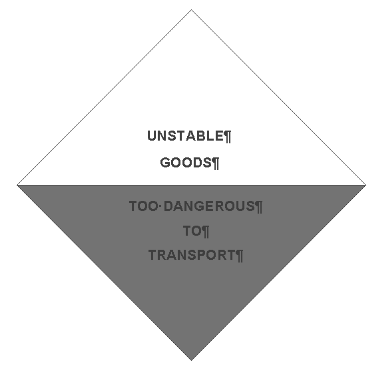

Goods too dangerous to be transported | Goods listed in Appendix 5 of the ADG Code and goods determined to be so by the Authority | ADG Code |

Combustible Liquid: C1 C2 | Any liquid other than a flammable liquid that has a flashpoint, and that has a fire point less than its boiling point. Combustible Liquid with a flashpoint > 60.5°C and ≤ 150°C Combustible Liquid with flashpoint > 150°C | AS 1940 – The storage and handling of flammable and combustible liquids |

1.10 Three classes of goods are not covered by this part of the regulations. These classes include:

- Classes 1 (explosives);

- Class 6.2 (infectious substances);

- Class 7 (radioactive substances); and

- Asbestos.

1.11 Other Commonwealth, State or Territory legislation may apply in relation to these goods.

1.12 Regulation 8.02(2) specifies other dangerous goods that are not covered by this part of the regulations and therefore, this code:

Dangerous goods in transit.

- Dangerous goods are in transit if they are supplied to a workplace in a container that is not opened or are used at the workplace and the goods will be kept for no more than five (5) consecutive days.

Dangerous goods in a fuel system or equipment or that are essential to the operation of a fuel system or equipment.

- batteries connected to and are essential for the operation of mobile plant, equipment, vehicles, boats, aircraft and appliances;

- fuel in fuel tanks and systems connected to and are essential for the operation of mobile plant, equipment, vehicles, boats, aircraft and appliances; and

- dangerous goods contained in portable firefighting or medical equipment deployed for use at the premises.

1.13 Even though these goods are not specifically covered under Part 8, the OHS (CE) Act general duty of care still applies.

1.14 It is a requirement that the amount and location of goods in transit are included on the manifest register and site plan and they are properly packaged and labelled.

2.1 Division 8.2 of the regulations outlines duties for those persons who manufacture, import or supply dangerous goods to Commonwealth workplaces.

2.2 Under the OHS(CE) Act, where a person who is not the manufacturer, imports goods, but does not have a place of business in Australia at the time the goods are imported, they are deemed to be the manufacturer.

2.3 The importer of dangerous goods is subject to complying with all manufacturers duties in the regulations.

2.4 Subdivision 8.2.1 outlines the duties of manufacturers of dangerous goods including, but not limited to:

- determining substances as dangerous goods; and

- providing safety information.

2.5 Regulation 8.09 specifies that where a manufacturer of dangerous goods is aware that employees at work will use a substance, the manufacturer be required to determine whether that substance is a dangerous good or not.

2.6 To make a determination, if the goods are specifically listed, the manufacturer should refer to chapter 2 of the ADG code. If the goods are not listed, the determination should be made according to the criteria in the ADG code.

2.7 The manufacturer is required to make this determination as soon as possible prior to the goods being manufactured. The determination of a dangerous good must be in writing and kept for the whole period the goods are manufactured.

2.8 The same process applies in relation to combustible and flammable liquids, however, AS 1940-2004 is the reference source rather than the ADG Code.

2.9 Regulation 8.10(1) Prior to, or at the time of delivery, a manufacturer must prepare and provide a material safety data sheet (MSDS) and other safety information to suppliers and employers where it is expected that employees will be using the supplied dangerous goods. This part does not apply to those manufacturers who supply C1 or C2 combustible liquids.

2.10 If requested, the manufacturer must provide any relevant and available information on the dangerous goods that is not contained in the MSDS.

Content of MSDS

2.11 An MSDS provides information to a person to assist with the safe storage and handling of dangerous goods. It also provides information to persons required to enter a workplace following an accident, with the exact properties of the dangerous goods used at that workplace.

2.12 An MSDS must include the name of every ingredient of the dangerous goods unless the identity of an ingredient is commercially confidential. Ingredients include diluents, solvents, wetting agents, stabilisers, inhibitors, and adulterants.

2.14 Regulation 8.10(7) allows a manufacturer to use the generic name of the ingredient if naming the goods would cause commercial disadvantage. This only applies if the ingredient is not a dangerous good and it does not have a known flow on effect.

2.15 Instead of naming the ingredient, the manufacturer may include a statement in the MSDS that the ingredient has been determined not to be a dangerous good. However, if there is a medical emergency involving the goods listed on the MSDS the manufacturer must disclose the name of the ingredient.

Review of MSDS

2.16 Regulation 8.10(5) says an MSDS must be accurate, kept up to date, and contain enough information to provide comprehensive advice on the dangerous goods. An MSDS should be reviewed at least every five (5) years, and it should be updated immediately when new information becomes available.

Guidance on MSDS

2.17 Regulation 8.10(2) clarifies that all MSDS must comply with the new National Code of Practice for the Preparation of Material Safety Data Sheets NOHSC: 2011 (2003) after 24 April 2006.

2.18 Other safety information may include, but is not limited to:

- summary reports produced under the Industrial Chemicals (Notification and Assessment) Act 1989 (Commonwealth); and

- where it is available, other users may have specific information relating to the conditions for safe use, compatibility and chemical stability under particular conditions.

2.19 Regulation 8.11(1) specifies that manufacturers of dangerous goods must contain, package, and label goods in accordance with the ADG Code before supplying the goods for use.

2.20 The manufacturer must ensure all information important to protect the health and safety of employees is included on the label.

2.21 Subdivision 8.2.2 outlines the duties of suppliers of dangerous goods including but not limited to:

- containing the goods;

- packaging and labelling the goods;

- filling gas cylinders; and

- providing safety information.

2.22 Regulation 8.11(2) specifies that any person, who supplies dangerous goods, must ensure the goods have been contained, packaged and labelled in accordance with the ADG Code before supplying the goods for use.

2.23 Regulation 8.11(2) does not apply in cases where retailers receive packaged dangerous goods in a container provided by the purchaser. However, retailers must ensure that the container:

- will not react with the dangerous goods;

- was constructed to contain the dangerous goods;

- is not damaged;

- is clearly marked with the name of the dangerous goods; and

- cannot be mistaken for containing foodstuffs.

2.24 Regulation 8.11(5) requires that when a person fills a cylinder, disposable container or aerosol container with Class 2 dangerous goods, such as gas, the cylinder or container must comply with paragraph 3.8.2 and Appendix 2 of the ADG Code.

2.25 The cylinder or container must be labelled and packaged in accordance with the ADG Code and provide all necessary information to protect the health and safety of persons using the cylinder or container.

Filling the cylinder

2.26 Cylinders are:

- generally designed to be used with a specific gas or group of gases;

- distinctively painted or marked to identify their contents; and

- have fittings that are only suitable for a particular gas.

2.27 Before filling the cylinder, an inspection of the valves, fittings, and protective devices such as neck rings and shrouds should be checked to ensure good working order. The use of adaptors are discouraged unless approved adaptors have been authorised by the original supplier of the gas or the manufacturer of the cylinder.

2.28 Cylinders must be marked appropriately to indicate they have been tested to withstand design pressures and display the period that the test is valid, (which can be up to 10 years). An imported gas cylinder should only be filled if it complies with AS 2030.1-1999 Cylinders for compressed gases.

2.29 A cylinder should not be filled if it:

- is not designed to be filled with gas;

- shows evidence of excessive corrosion or other damage

- shows any indication of leakage ; and

- is outside its current test date.

2.30 Regulation 8.12 requires suppliers to provide an MSDS the first time dangerous goods are supplied to a workplace. The supplier must also provide a copy of the current MSDS at any time the employer requests one.

2.31 This does not apply to a person who is a retailer and supplies packaged dangerous goods that are intended for retail display and sale.

2.32 Regulation 8.13 states that when requested, the supplier must provide any further information that is not contained in the MSDS, if it is relevant to the safe storage and handling of the goods.

2.33 Regulation 8.14 requires a person, who installs or supplies structures or plant at a workplace, which is expected to be used by employees, to ensure the plant or structure:

- is suitable for use with the dangerous goods it is intended to contain;

- conforms with the original design of the plant or structure without modifications; and

- is prevented from unintentional movement.

2.34 The supplier or installer must provide the employer with all information relating to:

- the installation, testing, commissioning, use, inspection, maintenance, dismantling and disposal of the plant or structure;

- explaining how the plant or structure should be operated and maintained; and

- stating any conditions or specifications that should be complied with to ensure the safety and health of employees when the plant or structure is in operation.

Initial design stage

2.35 The initial design of a plant or structure is an important stage to control the hazards and risks associated with storing and handling dangerous goods. If an employer engages a person to design plant for use by employees at work, the employer must ensure that the person is provided with relevant information about matters relating to the plant that may affect health and safety.

2.36 Where a structure or plant has been designed and built for use with a specific dangerous good, care should be taken if the plant is to be used with different goods. The employer should re-assess whether the plant is suitable for use with that good.

2.37 It may be necessary to put in place additional safeguards, such as barriers to guard against the plant or structure being damaged. If different risks are present, any decision to use the plant will need to take into account whether these risks can be controlled.

2.38 Part 4 of the regulations provides further guidance on the supply, installation and maintenance of plant and structures.

3.1 Division 8.3 outlines the duties of employers in relation to the storage and handling of dangerous goods.

3.2 This part of the code is designed to assist employers to meet the requirements of the regulations. Duties of employers include:

- control risks and hazards through a risk management process;

- provide safety information;

- provide induction and training sessions;

- supervise employees;

- ensuring placards are positioned within the workplace correctly;

- prepare a register of emergency procedures where there are large quantities of dangerous goods;

- provide notification as required to Comcare in relation to dangerous goods; and

- consult with employees.

3.3 The SRCC recommends risk management as the preferable method for controlling risks. Risk management may be defined as:

- a method of assessing and controlling risks associated with an activity, function or process;

- the systematic application of organisational resources to the tasks of identifying, analysing, assessing, controlling and monitoring exposures to risk and adverse effects of such risks;

- the employer’s responsibility and should be conducted in consultation with employees and/or their representatives;

- an examination of what could harm a person which allows employers and employees to assess what precautions should be taken to prevent harm at work. In making such assessments employers and employees may:

- compare its control to other similar working environments,

- consult with industry associations and/or involved unions,

- consult with specialists, and

- consult with Comcare.

- a system which allows employers flexibility to devise tailor-made solutions to control risks in their workplace;

- a process which need not be awkward or complicated ; and

- an opportunity which allows all persons in the workplace to be consulted and possibly agree on what rules should apply.

3.4 Incidents from the storage and handling of dangerous goods can be prevented and managed by observing the following principles of risk management:

- hazard identification (Subdivision 8.3.1);

- risk assessment (Subdivision 8.3.1); and

- risk control (Subdivision 8.3.2).

3.5 Regulation 8.15 requires an employer to identify any hazard associated with the storage or handling of dangerous goods foreseeable..

3.6 Hazard identification should highlight activities in the workplace that may affect persons involved with storing and handling dangerous goods.

3.7 In order to identify the hazards associated with the storage and handling of dangerous goods the employer should:

- collect information on potential hazards using sources such as MSDS, consult with employees, suppliers or other persons with expertise;

- conduct regular inspections of the workplace and the methods of storage and handling;

- examine plans of the workplace including buildings, water, gas, electricity, compressed air, steam, drains, fire services, chemical pipelines, roads, access ways and engineering specifications of relevant plant; and

- discuss risks with the employers of nearby workplaces and the emergency services authority.

3.8 Employers must keep a written record of each hazard identified.

3.9 Hazard identification for structures, plant, equipment, systems of work and activities used in the storage and handling of dangerous goods involves collecting information on:

- physical components or characteristics that have the potential to harm the safety and health of a person and/or cause damage to property and the environment, either in their own right or in conjunction with the dangerous goods;

- systems of work, including normal operating procedures and unusual operating conditions which could give rise to harm or damage; and

- activities that may pose a threat to the dangerous goods.

3.10 When identifying the hazards, the employer should be aware of:

- the chemical and physical reactions of dangerous goods;

- possible reactions between dangerous goods and any plant, structures or other substances;

- manufacturing, transfer or transport processes at the workplace involving dangerous goods;

- plant and other structures used in the storage or handling of dangerous goods

- any information about the hazardous properties;

- the kind and characteristics of incidents which may be associated with dangerous goods;

- the location of dangerous goods; and

- environmental factors that may have an effect on the goods.

3.11 A number of important sources that may assist employers to identify hazards include safety information, inherent hazards, incidents and external factors.

Safety information

3.12 Safety information such as MSDS can provide the employer with information on the chemical and physical properties for use and safe handling requirements for the dangerous goods.

3.13 The chemical and physical properties of the dangerous goods that may represent or contribute to hazards in the particular storage and handling situation include:

- physical state;

- flashpoint, fire point and explosive limits;

- viscosity;

- density;

- particle size;

- vapour pressure;

- solubility and pH;

- reactivity;

- boiling and/or freezing point or range;

- electrical and/or heat conductivity; and

- the nature and concentration of combustible products.

Inherent hazards

3.14 The secondary dangerous goods hazards such as Subsidiary Risks are equally important as the primary dangerous goods classification. The inherent hazards of dangerous goods may include:

- fire;

- explosion; and

- toxic effects such as inhalation, ingestion, absorption through the skin or eyes, or corrosive action.

Incidents

3.15 Records or historical data related to injuries and illness may prove to be valuable sources of information.

3.16 Both internal and external incidents including dangerous occurrences and near misses that have occurred can provide useful information about the hazards or risks associated with dangerous goods.

External factors

3.17 Hazards may arise from sources outside the workplace.

3.18 Other hazards surrounding the workplace which are not related to dangerous goods may have the capacity to directly impact on the goods in a hazardous way. Fire risks are increased from areas where grass has been left to over grow or combustible items such as timber or cardboard boxes have been stored or dumped.

3.19 The proximity of railway lines, pipelines, mobile phone repeater towers, and protected places such as schools and public buildings are required to be taken into consideration when assessing the hazards associated with the storage and handling of dangerous goods at a workplace.

Other sources

3.20 Other activities which are not directly related to the storage and handling of dangerous goods may generate potential hazards within the workplace. This may require the consideration of any adjacent storage areas that contain dangerous goods or the proximity of other work areas when identifying hazards.

3.21 Other sources of information which may provide the employer with information on the hazards and risks associated with dangerous goods include:

- package markings and labels;

- manufacturers or suppliers of dangerous goods or equipment;

- dangerous goods authorities;

- National Industrial Chemical Notification and Assessment Scheme (NICNAS) summary reports;

- sources listed in the National Code of Practice for the Preparation of Material Safety Data Sheets NOHSC: 2011 (2003);

- fire services;

- Office of the Australian Safety and Compensation Council (OASCC) (formerly NOHSC);

- trade union, employer and/or industry associations; and

- occupational health and safety consultants.

3.22 Having collected information about the dangerous goods and their potential hazards, the next step is to consider all processes and activities at the workplace, in relation to the storage and handling of dangerous goods.

3.23 All processes should be examined in detail. The employer should consider not only the official process but also how the procedures are actually performed and any short cuts that may occur. It is valuable to conduct a periodic walk through inspection of the workplace to observe actual practices relating to the storage and handling of dangerous goods.

3.24 A risk assessment determines whether there is a risk of injury to people or damage to the property from the storage and handling of dangerous goods. The purpose of a risk assessment is to:

- identify those risks that are required to be controlled;

- assist in making decisions regarding the priority in which risks need to be controlled; and

- develop a schedule for controlling all risks as soon as practicable.

3.25 Regulation 8.16(1) requires that every hazard is identified under Regulation 8.15; the employer must assess all risks associated with each hazard associated with dangerous goods.

3.26 The employer should decide if there is sufficient expertise within the workplace to conduct the risk assessment or whether external advice is required. This decision will depend on the skills and experience available to undertake the risk assessment. The expertise required will depend on the classes of dangerous goods involved and the complexity of processes employed in the particular workplace.

3.27 At workplaces where complex dangerous goods processes are involved, it may be more effective to use a more highly structured process such as Hazard and Operability Studies (HAZOP) or Hazard Analysis (HAZAN) to guide the hazard identification and risk assessment process. In some situations, it may be necessary to undertake a quantitative risk analysis (QRA) to assist in understanding the risks involved.

3.28 Regulation 8.16(3) requires that a review of each risk assessment should occur at least once every 5 years. A review must be carried out prior to the introduction of changes such as when:

- dangerous goods not normally kept at a workplace are introduced;

- dangerous goods are stored and handled in different areas since the last assessment was completed;

- new or improved control measures have become more practicable or safer; or

- plant or structures are modified.

3.29 Regulation 8.16(4) requires the employer to keep a written record of each risk assessment. The employer must keep the records up-to-date and those records must be made available to:

- Comcare on request;

- employees which may be affected by any risk contained in the assessment; and

- all health and safety representatives.

3.30 The amount of detail required to be recorded will vary depending on the nature and severity of the risks identified. If a risk does not need to be controlled, it may not be necessary to maintain an extensive record of the risk.

3.31 Generally, risk assessment records should include the:

- name of the workplace;

- names of assessors and their appointments;

- date the assessment was conducted;

- areas within the workplace that were assessed;

- dangerous goods for which the MSDS or other information were reviewed;

- processes or activities that were assessed;

- details of all risks identified;

- decisions about the risk and why they were made;

- practicality of reducing the risk; and

- controls in place to eliminate risks however if this is not possible, employers must control the risk.

3.32 Subdivision 8.3.2 outlines the necessity for a risk control process to be in place.

3.33 After completion of a risk assessment, consideration must be given to controlling the risks. The three main steps in risk control are:

- development and implementation of control policies and procedures, in consultation with employees;

- monitoring the effectiveness of the control strategies; and

- reviewing as necessary.

3.34 Part 4 of this code discusses risk control strategies in further detail.

3.35 A risk management program is a repeating cycle - even though one hazard may be eliminated or controlled, the process continues. You will require a systematic monitoring and review system to identify the potential for new hazards which may be introduced into a workplace. These hazards can be due to circumstances such as:

- new technology, equipment or substances;

- new work practices or procedures;

- changes in work environment, e.g. moving offices, staff reduction; and

- new staff with different skill/knowledge levels.

4.1 Regulation 8.17 specifies that risks can be controlled by either:

- eliminating the hazard; or

- if this is not practicable, reducing the risk as far as is practicable.

4.2 A focus should be placed upon eliminating risks, for example, not using the dangerous goods at all. However, where the risk cannot be eliminated, it is necessary to implement a strategy that will reduce the risk as far as practicable. This may be achieved by:

- using dangerous goods with a lower risk; and

- reducing the quantity of dangerous goods at the workplace.

4.3 If a risk cannot be eliminated or reduced, the employer must implement appropriate engineering controls and systems of work to assist in reducing the risk.

4.4 Effective control strategies should be introduced based on hazard identification and risk assessment process along side other activities in the workplace.

4.5 When developing risk control strategies, the action to control one risk should not create another. A particular risk control should not be applied in isolation unless the employer is satisfied that the other risk controls implemented will not be jeopardised.

4.6 Documents specifying risk controls generally apply to particular classes of dangerous goods. When using these documents, employers are to be aware that most of the risk control systems have been prepared as an integrated package, which involves engineering and administrative controls in addition to personal protection equipment. The application of risk controls is therefore likely to satisfy the risk control duty imposed by the regulations if all of the associated controls specified in the standard, having a bearing on the particular risk, are adopted.

4.7 The most effective method of risk reduction is eliminating hazards and risks at the source which may include either the dangerous goods or activities which increases the level of the risk.

Eliminate the use of dangerous goods

4.8 Dangerous goods maybe essential for the operation of the workplace and therefore, elimination is not practicable. However, there may be situations where eliminating some dangerous goods may be appropriate. Some examples are:

- An employer could use a physical process rather than a chemical process to clean an object such as using high-pressure water or steam rather than solvents or use water based paints rather than solvent based paints;

- Where appropriate, use clips, clamps, bolts or rivets rather than adhesive; and

- Chlorine may be produced by electrolysis rather than storing/handling other dangerous goods which are comprised of chlorine or its compounds at the workplace.

Eliminate the activity

4.9 Designing the layout of a workplace is an effective way of minimising risks and hazards. Considerations to workplace layout may include:

- Ensuring that storage and handling areas are not used as thoroughfares to reduce the risk of collisions at the workplace; and

- Restricting employees from carrying ignition sources or prohibiting employees from having matches, lighters, mobile phones, or spark producing tools in work areas.

4.10 Substitution is the replacement of dangerous goods or hazardous activities that present a higher degree of risk associated with other dangerous goods, substances or activities of a lower risk. Substitution of a dangerous good for a product that is not dangerous can often be cost effective. The employer may be required to consider the following examples:

- Substituting a less volatile material to control a vapour hazard may cost less than the installation and maintenance of a mechanical ventilation system;

- It may be reasonable to substitute a non-dangerous good for a dangerous good by degreasing with a detergent instead of a chlorinated or volatile solvent;

- Substitute a flammable liquid with a combustible liquid; and

- Use dangerous goods with a single hazard as indicated by a single class without a subsidiary, risk rather than mixing goods that have one or more subsidiary risks.

Safer activities

4.11 Processes should be designed for activities which have higher risks and goods involved may be substituted for those which have a lower risk. These may include:

- using diluted acids and alkalis rather than concentrates;

- use stretch wrapping rather than flame heat shrink to palletised goods;

- use a pallet cage rather than stretch wrapping in areas where static electricity generated during the wrapping process would increase hazards;

- use a solid in paste or pellet form rather than as dust/powder;

- apply paint by brush rather than spray

- transfer packages by conveyor rather than forklift

- use non-sparking tools in a hazardous atmosphere

Reducing quantities

4.12 Reducing quantities of dangerous goods at the workplace usually leads to an overall reduction in risk. Methods of inventory reduction to minimise the risks of storage of dangerous goods at the workplace include:

- just in time ordering rather than storing large quantities of dangerous goods; and

- prompt disposal of dangerous goods which are no longer required.

4.13 Where a workplace does not have the appropriate facilities to store dangerous goods safely, an alternative storage location that is appropriate should be used to store the goods when the goods are not in use.

4.14 Careful planning is required to achieve an optimum inventory level. It may not always be possible to reduce the quantities of dangerous goods that are stored and handled at a workplace, even though this will usually reduce risk.

4.15 The additional movement associated with frequent delivery of dangerous goods that are required to stabilise other dangerous goods stored and handled at the workplace may create further risk.

4.16 Isolation is the separation of dangerous goods from people and other property, including other dangerous goods. Isolation may be achieved by enclosing, separating by distance or by the use of barriers. The principles of isolation should be a high priority when establishing new workplaces for the storage and handling of large quantities of dangerous goods. Isolation methods may include:

- Distancing the dangerous goods from protected works, other dangerous goods people and other properties so interaction is not possible;

- Enclosing a hazardous activity;

- Storing incompatible dangerous goods, such as Class 5.1 oxidizing agents and flammable or combustible materials, in separate buildings which are separated by sufficient distances so that interaction is impossible and an incident in one area will not involve another; and

- Installing a screen wall such as a vapour barrier that has an appropriate fire resistance level to provide additional isolation.

4.17 Engineering controls including structures, plant, equipment and processes that are designed to reduce the hazards associated with the storage and handling of dangerous goods, such as:

- minimising the generation of dangerous goods;

- containing or suppressing dangerous goods including their vapours and dusts;

- eliminating, confining or controlling hazardous processes, plant or equipment that may pose some threat to the dangerous goods;

- protecting dangerous goods and installations from external factors such as rain or sunshine; and

- limiting the area of contamination in the event of spills or leaks.

4.18 Examples of engineering controls may include:

- Enclosing the dangerous goods or external hazard;

- Providing adequate ventilation;

- Sparging or blanketing exposed liquid surfaces with an inert atmosphere to prevent an explosive atmosphere forming;

- Developing automatic processes to eliminate human error;

- Fitting sensors and controls for liquid levels, pressure or temperature to minimise loss and formation of hazardous atmospheres and eliminate overflow and uncontrolled reactions;

- Specify the right electrical circuitry;

- Construct barriers between incompatible goods; and

- Install suitable devices to protect installations from external hazards.

4.19 Administrative controls are systems of work that can eliminate or reduce risks that consist of properly designed, implemented work practices and procedures that are often used in support of engineering controls.

4.20 The most important aspect of introducing effective administrative controls is ensuring people are properly informed and trained to implement the controls.

4.21 Administrative controls rely on agreed work practices and procedures between the employer and employee. It is important that these controls are simple and developed to match the skills and capabilities of the people who will use them.

4.22 Examples of administrative controls may include:

- document safe work procedures that describe the correct methods for performing all activities;

- implementing operating procedures that ensure the integrity of structures, plant and equipment are maintained at all times;

- conduct training and supervision to provide the necessary knowledge and skills required to ensure correct procedures are followed safely;

- introduce procedures that limit the number of people in the dangerous work area but also prevent lone occupancy;

- introduce job rotation for employees to limit the period of exposure;

- introduce procedures to ensure that work involving inspection, maintenance, repair testing and cleaning is carried out to minimise risk;

- regularly clean contamination from walls and surfaces, dust and drip removal from all work areas and ensuring lids on containers are in place when not in use or when being moved;

- monitor workplaces to ensure that safe working conditions are maintained;

- develop procedures for waste disposal and effective decontamination and inventory control;

- develop well designed and rehearsed emergency procedures; and

- enforce controls on activities that are inconsistent with the safe storage and handling of dangerous goods, such as eating, drinking, and smoking.

4.23 PPE consists of devices and clothing that provide individual employees with additional protection from hazards. When used correctly, they are used in conjunction with other control measures to further reduce risk.

4.24 As a matter of principle, PPE should not be used as the sole control measure except where no other measures are practicable. However, its use with other control measures may often reduce the risk of personal injury.

4.25 For PPE to be effective, an employer must ensure protective devices are selected that provide the required level of protection from risks associated with the particular task. Only approved clothing and equipment are to be used.

4.26 It is imperative that all employees understand the proper use of the equipment and the circumstances where it should be used. Detailed instruction for the correct use of personal protective equipment and the circumstances it is used are essential.

4.27 All equipment is to be readily available, clean and sized correctly for all employees who are required to use it. An effective system of cleaning and maintenance should be devised and implemented by trained staff in accordance with a maintenance and servicing schedule.

4.28 In some cases, it will not be possible to reduce the risks to an acceptable level without the use of PPE. An MSDS for dangerous goods will normally contain recommendations on the selection and use of personal protection equipment for that particular dangerous good. This advice should be followed unless the employer determines, following a risk management assessment and in consultation with employees, that other protection measures would be more appropriate. More guidance appropriate to particular types of PPE can be located in Australian Standards AS1940-2004 (Storage and handling of combustible material).

4.29 One of the best times to develop a risk control strategy is at the design stage. Well-considered design can reduce establishment costs and help avoid ongoing operational costs that can result from a poorly set out and complex systems of work. Considerations at the design stage may be:

- Designing the workplace layouts by ensuring the storage of incompatible substances and fire risk goods are located away from any bulk storage of combustible goods; and

- Buildings can be purpose designed and constructed of materials suitable for the types of goods to be stored and handled at the workplace.

4.30 It is not always possible to design the workplace from a blank canvas. In many cases, the storage and handling of dangerous goods must be accommodated within an existing workplace where there are constraints with the location of buildings and outside storage areas.

4.31 There is often limited scope for redesigning access to the workplace or within the workplace. However, it will still be possible to redesign systems of work and processes to reduce the risks associated with the storage and handling of dangerous goods.

Process design

4.32 Risks associated with a chemical or a physical process should be designed out by adopting the most appropriate work method or system of work.

4.33 Where there is a choice of chemical reactions that involve dangerous goods, each possible reaction pathway will have certain inherent hazards and risks associated with it.

4.34 Similarly, there may be a choice of physical processes that are available to achieve the same result. For each of the alternatives, the hazards should be identified and their relative risks assessed. The processes that result in the lowest overall risk should be selected.

Design of structures and plant

4.35 All structures and plant associated with the storage and handling of dangerous goods should be:

- designed so the risks associated with each item are eliminated as far as practicable, while ensuring the risks of the total system are minimised;

- manufactured to a high standard within the design specification, and from quality, durable materials which will not be adversely affected by the planned storage and handling of the dangerous goods;

- installed only after all hazards associated with the installation have been identified, their risks assessed and control measures implemented as required;

- commissioned only after undergoing thorough testing to ensure that any unpredicted hazards have been identified, control measures implemented and agreed procedures developed to ensure safe operation;

- operated only in accordance with the agreed procedures by authorised personnel who have received appropriate training in the correct procedures;

- maintained and repaired as required to ensure additional hazards or increased risks are prevented during normal operation or breakdown; and

- if required, decommissioned in a manner which does not introduce additional risks or, where this is not practicable, the additional risks are minimised and controlled.

4.36 It is more effective to incorporate isolation and engineering controls into structures and plant at the design stage, rather than to attempting to modify existing designs and installations. It may not be practicable to retrofit control features such as spill containment or natural ventilation once the plant or structure has been installed.

4.37 Once the employer has determined the risk control measures mechanisms should be implemented, applied and practised on a continuous basis.

4.38 Over time, there is an ever-increasing risk of familiarity when working with a hazard. This may lead to complacency and shortcuts with potentially tragic outcomes may result. Employers should consult employees and their representatives regarding ways to guard against this occurring.

4.39 Where there are a number of risks and administrative control measures to be implemented in a workplace, a further administrative control such as a Safety Management System (SMS) may be required to monitor the compliance and effectiveness of these controls.

4.46 Whether or not a SMS should be developed and the detail that it contains is dependent on the nature of activities at the workplace. Many corporate and proprietary systems exist, which have common features, such as:

- scope, policy and objectives;

- assignment of responsibilities;

- operating procedures;

- standards, codes and laws;

- management of change;

- scheduling and establishing procedures for reviews; and

- system auditing and corrective action.

4.47 Only people who have the appropriate levels of qualifications, knowledge, skills and experience should be in control of work areas. Arrangements for adequate supervision of all workers should be in place at all times where dangerous goods are stored and handled.

4.48 All risks with unacceptable consequences must be actioned immediately. It may be necessary to close down operations to eliminate the risk in the short term until effective risk control measures are in place.

4.49 If breaches of the regulations occur, action must be taken as soon as practicable to address the breach and any risk resulting from that breach must be eliminated or reduced as far as is practicable.

5.1 Regulations 8.18 to 8.27 relate to the duties employers must adopt to control risks, including:

- physical separation;

- keeping dangerous goods stable;

- impact protection of structures, plant and containers;

- maintaining the integrity of containers;

- transfer of dangerous goods;

- fire protection; and

- emergency preparedness.

5.2 Regulation 8.18 requires an employer to eliminate any risk to a person, protected place or any property at, or outside the workplace which may result from a dangerous occurrence, involving the storage or handling of dangerous goods.

5.3 If it is not reasonably practicable to eliminate the risk, the employer must reduce any risk by separating the dangerous goods from the person, protected place or other property.

5.4 Physical separation is the principal method by which risks to other occupancies are minimised. Separation fulfils a dual purpose by:

- protecting other occupancies from dangerous goods; and

- protecting dangerous goods from the other occupancies.

5.5 Separation may include:

- isolating the dangerous goods, by distance;

- using effective barriers; and

- a combination of both.

5.6 In deciding what may be effective to control a specific risk, an employer should consider the types of hazard and risks the dangerous goods stored and handled in the workplace may pose to adjacent properties. This analysis should include:

- the quantity of dangerous goods stored and handled in the work area;

- the type of installation and the processes applied to the dangerous goods in the work area and their associated hazards;

- all other activities in the work area which may increase the risks; and

- any control measures in place that will reduce the risks.

5.7 If possible, separation distances should be applied in a way that risks would not require additional control measures. However, if this is not possible, barriers may be required.

5.8 The employer should consider any risk posed to a barrier used instead of or, in conjunction with separation, when used to isolate dangerous goods. For example:

• the effect that climatic elements may have on a barrier and its effectiveness;

• the level of fire resistance provided by the barrier; and

• the structural capability which may be required to withstand weather and overpressure resulting from internal or external incidents.

5.9 Regulation 8.19 requires employers to separate dangerous goods from all other goods they are not compatible with to assist in the prevention of any dangerous interaction.

5.10 Segregation would generally apply in this instance as it involves storing and handling incompatible goods in separate areas, or using physical barriers or distances if they must be stored within the same area.

5.11 As a rule, dangerous goods should not be stored above or below other goods with which they may interact.

5.12 As far as is practicable, an employer must not allow dangerous goods to:

- interact with incompatible goods; and

- contaminate food, food packaging and personal use products, such as cosmetics, cigarettes, medication and toiletries.

5.13 Workplace systems and procedures must be developed and enforced which includes the training and supervision of personnel to ensure the segregation of incompatible substances at all times.

5.14 Regulation 8.20 requires that unless the goods are about to be used in a manufacturing process, an employer must ensure that as far as is practicable they are stored or handled to ensure they do not accidentally become unstable, decompose or change. This will assist in avoiding increased risks associated with the goods, or creating a different hazard from those already identified as many dangerous goods can be highly reactive, unstable, or self-reactive except under controlled conditions.

5.15 An employer must make sure the dangerous goods are stored in accordance with the ADG Code or the manufacturer’s specifications, if the stability of the goods depends on the employer:

- maintaining specified proportions of substances that constitute the dangerous goods;

- including a stabilising ingredient; and

- keeping the goods at or below a control temperature.

5.16 This regulation does not apply to goods if they are about to be used in a manufacturing process.

5.17 Regulation 8.21 requires that to prevent damage from the movement of the structure or plant including any attached pipe work or equipment, an employer must ensure that structures or plant used for the storage or handling of dangerous goods are appropriately located and fixed to a stable foundation if necessary.

5.18 The most likely source of impact are vehicles or other mobile plant, an employer should also consider any threats from external sources such as nearby railways, airports or construction activities.

5.19 Measures required for preventing or controlling impact normally depends on the nature of risks. Impact protection measures may be necessary for:

- structures containing dangerous goods;

- plant and equipment including storage and process vessels, associated pipe work, pumps and controls;

- storage areas (including transit storage) for packages, IBCs and associated shelves and racks; and

- exposed parts of the fire protection systems.

5.20 Installation of crash protection measures, such as bollards and guardrails may provide impact protection. The design of these measures should absorb the energy of any reasonably foreseeable impact and minimise the likelihood of injury to anyone involved in the incident.

5.21 Regulation 8.22 requires that a container and the pipe work or equipment attached must be protected from damage, which may result from activities in the workplace.

5.22 Bulk containers are usually designed focussing on the storage of the goods rather than the impact from other objects. The employer should be aware of:

- the integrity of the container;

- location of the container; and

- any underground tanks.

Integrity of container

5.23 Understanding the risks associated with leaks from bulk containers, employers should pay particular care to factors that are required to maintain the integrity of the storage container in all operating conditions. Factors to consider include:

- structural soundness to withstand stresses from the product being stored;

- stability, rigidity and suitability of foundations;

- stresses imposed by pipe work and other attachments;

- atmospheric conditions including sun, wind and rain;

- the effects of external impacts; and

- the extent to which an acceptable level of corrosion is to be allowed for over the service life of the container.

Location

5.24 Bulk containers should be located to provide the minimum separation from other occupancies.

Underground Tanks

5.25 Underground tanks should be constructed, located and protected to eliminate risks and threats to the environment from:

- failure, usually due to corrosion or stress loading which may allow the escape of dangerous goods into the water table; and

- spills from above ground pipe work and filling points.

5.26 The seepage of dangerous goods from an underground tank, or through faulty foundations of an underground tank, may go undetected for years. Leaked material can migrate through the water table and present a risk to people and property for considerable distances from the leaking tank.

5.27 Other risks involved with the seepage of underground tanks are the threat of dangerous goods building up in locations such as telecommunication pits or basements of buildings. This may endanger the people who are required to access these locations for the purpose of employment or residence.

5.28 Underground storage installations for bulk dangerous goods and combustible liquids are usually subject to additional controls from environmental authorities, and local government.

5.29 Regulation 8.23 requires that if a spill, leak or accidental release of dangerous goods occurs, appropriate actions must be taken to contain the dangerous goods within the workplace.

5.30 Leaving containers open when not in use is one of the principal sources of dangerous goods incidents. This leads to spillages, generation of ‘hazardous atmosphere’ and fire. Procedures, supervision and training should ensure containers are sealed when not in use.

5.31 The design of a spill containment system should ensure that the risks associated have been assessed and it is large enough that all spills can be held safely until cleaned up. Factors the employer should be aware of include:

- the nature of the dangerous goods (whether liquid or solid);

- the quantity of the dangerous goods;

- the size of the largest container or reasonably foreseeable largest spill;

- the potential impact if the dangerous goods escape to the environment;

- whether it is necessary to provide for the management of firewater at an incident;

- a separate spill containment is provided for incompatible goods;

- the materials used to construct the containment system, as well as any materials used for absorption, are compatible with the dangerous goods;

- other materials in the vicinity that will prevent contamination of groundwater or soil; and

- the systems integrity will be maintained in any foreseeable incident.

5.32 Transferring dangerous goods generally poses a far greater risk than those experienced in static storage areas. The goods will frequently be unconfined at some stage of the transfer process that may include pouring or pumping dangerous goods from one contained to another.

5.33 Regulation 8.24 requires employers to ensure any risks associated with the transfer of dangerous goods to, from or within the workplace are eliminated. If elimination is not possible, the employer must control the risk by avoiding spillage or overflow, reducing static electricity, vapour generation, ensuring transfer fittings are compatible, avoiding sources of ignition and ensuring that the dangerous goods remain stable.

5.34 The transfer system design and its operation should achieve the safe transfer of dangerous goods and take into account factors including:

- hazards associated with dangerous goods and the proposed method of transfer;

- required flow or transfer rates and quantities; and

- external hazards and adjacent activities.

5.35 It is essential that all components of the transfer system are compatible with, or suitably protected from, the goods being transferred. The ADG Code also includes specific requirements for the transfer of dangerous goods.

Preventing spills

5.36 Particular care is required where spillage may occur away from spill containment installations, such as the transfer by pipe work through areas without bunding.

5.37 Methods for preventing spills and overflow include:

- overflow protection equipment on receiving vessels;

- flow and pressure regulators on pipe work or pumps;

- interlocking of valves and switches; and

- systems for detecting losses from pipe work and fittings, such as static pressure loss detectors, measurement to determine losses in transfer or external sensors.

Static electricity

5.38 The prevention of static electricity generation must be controlled when transferring non-conductive flammable and combustible liquids, finely divided combustible powders and any other dangerous goods with a flammability hazard.

Vapour emissions

5.39 Vapour emissions resulting from transfer can be minimised by considering the following:

- the use of enclosed transfer systems;

- keeping lids open only for the minimum period required for transfer;

- minimising exposed surface areas;

- avoidance of splash filling;

- minimising the temperature of liquids being transferred; and

- providing extraction ventilation for all sources of vapour.

5.40 Compatibility is required for all items that may need to interconnect, including:

- hoses, couplings and associated fittings;

- earthing connections;

- vapour recovery connections; and

- telemetry where required.

5.41 Regulation 8.25 outlines the requirement to have a fire prevention and fire protection system in the workplace.

5.42 Workplaces must have fire protection and fire fighting equipment that is designed for use in relation to the types and quantities of dangerous goods, which are stored or handled at the workplace.

5.43 When assessing the appropriate fire protection methods, the employer must consider:

- the conditions under which the goods are stored and handled at the workplace;

- the fire load of the dangerous goods;

- the compatibility of the dangerous goods with other goods;

- risks from other sources; and

- proximity to other workplaces or premises.

5.44 The fire protection system must provide the capacity to quickly control and extinguish any fire that occurs involving the dangerous goods. It must also, effectively protect the dangerous goods stored within the workplace from any fire in adjacent properties.

5.45 The Building Code of Australia may not be sufficient for fire protection of different types of buildings. For the storage and handling of dangerous goods, additional fire protection from the goods and the particular hazards and associated fire loads are required.

5.46 The fire load will depend on the particular hazards of the dangerous goods and combustible liquids and on the quantities being stored and handled in the work area. Other factors that may influence the fire load and the amount and type of protection needed include:

- storage configuration, height, and density of the dangerous goods;

- location, design, type of construction and total floor area of the building or work area;

- nature of any structures, plant, and equipment including their materials of construction;

- type of operations in the building or work area, with particular attention to

whether the goods are bulk, or in open or closed packages;

- if any processing of dangerous goods occurs within the workplace.

5.47 The fire protection system should provide protection on and off the premises for:

- dangerous goods installation from other exposure

- other exposure from the dangerous goods.

5.48 Attention should be given to the types of structures present, with current and future activities.

Water supply

5.49 A reliable water supply will be required for the protection system at most premises where dangerous goods and/or combustible liquids are stored and handled. The supply must be sufficient to supply both the internal fire protection equipment and additional equipment, used by the emergency services authority controlling a fire at the premises.

5.50 Where sufficient supply is not available from the main water supply, it may be necessary to supplement this with additional water storage and/or pumps. If the local authorities permit it, water may be obtained from reliable alternative sources such as close by rivers and dams, using whatever resources are suitable.

5.51 The emergency services authority that is attending a fire at the workplace should be requested to conduct regular checks on the adequacy of the local water supply and pressure within the workplace.

Fire alarm systems

5.52 The design and installation of the fire alarm system should contain:

- automatic systems capable of being operated manually through the use of clearly identified alarm activators at convenient and safe locations, easily accessible to work areas;

- alarm signals that are distinguishable from any other signal to permit ready recognition, and is clearly audible throughout the premises;

- an effective visual system as an alternative, should be installed where there are high noise levels or the use of protective clothing may prevent the recognition of an alarm signal; and

- a system that remains operable if the main power supply fails.

5.53 Fire fighting equipment should be located so that:

- it is in a conspicuous position;

- it is readily accessible in the event of an incident, preferably being sited adjacent to exit doors or on exit routes;

- it is convenient to, and readily accessible from, the risk being protected; and

- all dangerous goods and other items being protected can be directly reached by the fire-fighting medium.

5.54 Installation, testing and maintenance of fire fighting equipment must be in accordance with the manufacturer’s specifications.

5.55 All fire fighting equipment is to be appropriately labelled. It may prove to be beneficial to the employer to confirm the labelling is correct with the relevant emergency services authority.

5.56 If at any stage the fire protection or fire fighting equipment becomes ineffective, the employer must ensure that any risk resulting from the loss of these items are assessed. If alternative resources cannot be obtained to provide the required level of protection, it may be necessary to cease operating until effective fire protection can be restored.

Hose reel systems

5.57 Hose reel systems must be located on each storey of a building where dangerous goods are stored and handled. Where the total floor area exceeds 300m², hose reels should reach every location and installations within the building. Appropriate hydrant hose systems may be substituted for fire hose reels, if there are trained persons capable of safely using the equipment.

5.58 Hose reels should be provided with a hose length of 36m, have appropriate signage, and are protected by a cabinet or other suitable means if it is in an environment where it may be damaged.

5.59 Foam hose reels should be capable of producing satisfactory foam that meets the manufacturers’ specifications, suitable for the risks being protected and are to be identified by appropriate signage.

Fire hydrants

5.60 Fire hydrants should be equipped with hose branch and nozzle except where it is not appropriate and prudent to do so, for example:

- where this equipment may be susceptible to theft; and

- there are no personnel properly trained to operate them.

5.61 External hydrants should be:

- in a convenient position, but in a safe distance from exit doors and hard standing areas;

- easily visible with appropriate identification signs; and

- capable of providing the appropriate coverage.

Monitors

5.62 Monitors are to be installed in accordance with manufacturers’ specifications and should be installed where fire control may require the direction of large quantities of firewater (or equivalent) at a fixed installation, with minimum exposure to risks for fire fighters.

5.63 Monitors should be installed in consultation with the relevant fire brigade.

Automatic sprinkler systems

5.64 Automatic sprinkler systems may comprise of:

- individual-actuation sprinklers;

- deluge sprinklers;

- foam sprinklers; and

- a combination of any of the above.

Portable fire extinguishers

5.65 Portable fire extinguishers should be clearly visible, readily available, unobstructed and convenient to the relevant risk but not adversely affected by hazardous or climatic conditions. AS (2444-2001) provides relevant information on the selection and storage of fire extinguishers.

5.66 Emergency procedures and a written emergency plan should be prepared where quantities of dangerous goods in a workplace are greater than the manifest levels set out in Schedule 7 of the regulations.

5.67 Regulation 8.26(a) requires emergency procedures be developed, implemented and maintained for all workplaces that store and handle dangerous goods. This ensures the safe handling of all assessed emergencies such as fire, spillage, vapour release, uncontrolled reaction and external threats.

5.68 The extent of emergency procedures required will depend on the size and complexity of the workplace, types and quantities of dangerous goods and the processes involved when the goods are in use.

5.69 Employers must communicate and train all employees and other relevant persons who may be affected if emergency procedures are required.

5.70 Emergency procedures should include:

- the means of raising the alarm;

- the method for the summoning the appropriate emergency services; and

- any actions to be taken by employees in an emergency to ensure the safety and health of all persons and to minimise damage to property and the environment.

5.71 An example of an effective emergency procedure is a simple one-page document; in point form, suitable for display on signs or carrying by employees or visitors as a pocket card.

5.72 Regulation 8.26(b) requires that appropriate clean-up equipment is available for use in case of an emergency.

5.73 Regulation 8.27 requires employers to ensure that an emergency plan is developed, implemented and maintained at the workplace where:

- dangerous goods with amounts larger than the manifest quantity in Schedule 7, are being stored and handled at the workplace; and

- dangerous goods of a Class mentioned in column 2 of an item of Schedule 7 are being stored and handled at the workplace.

Purpose of a plan

5.74 The purpose of an emergency plan is to minimise the effects of any dangerous occurrence or near miss at a workplace. The emergency plan should enable the employer to prioritise and focus on the most likely incidents. It should incorporate actions required for worst-case scenarios and should be adaptable in all circumstances dependent upon the severity and the type of incident.

5.75 The emergency plan should also ensure that appropriate clean-up equipment and material, such as absorbents and neutralisers are available for use in case of an emergency.

Consultation and communication

5.76 During the development of the emergency plan, employers should:

- consult with employees, employee representatives, and the relevant emergency service authority; and

- provide a copy of the plan to the emergency services who may then issue written advice to the employer about the plan. If this occurs, the employer should consider the advice.

5.77 Employers should consult with local government authorities for environment and planning to ensure compliance with any legislation and emergency planning in the jurisdiction. The employer should also consider consulting with neighbours if an emergency may affect adjoining properties.

5.78 The emergency plan should be communicated to all persons who may be affected by an emergency.

Content of emergency plan

5.79 The emergency plan should be comprehensive and should coordinate all aspects of emergency management, including:

- copies of all emergency procedures;

- responsibilities of key persons in managing emergencies;

- circumstances to activate the plan;

- systems for raising the alarm;

- estimating the extent of the emergency;

- summoning emergency services authorities in the event of an emergency is, or has the potential to become a dangerous occurrence;

- protection of all persons including detailed evacuation procedures and methods for accounting for all people at the workplace;

- isolation of the emergency area to prevent entry by non-essential personnel;

- roles of on-site emergency response teams;

- containment of any spillage;

- the requirement for fire-water retention to ensure that contaminated fire-water cannot enter waterways, drains or ground water;

- disconnection of power supplies and other energy sources except when required to maintain safety of a critical operation or to run emergency equipment such as fire booster pumps;

- prevention of dangerous goods or contaminated material of any kind from entering drains or waterways;

- provision of relevant information and assistance to the emergency services authority, both in anticipation of emergencies and when they occur;

- maintenance of site security throughout the emergency;

- provision for dealing with the public and the press; and

- site rehabilitation requirements.

Off-site considerations

5.80 Where any foreseeable incident may have effects beyond the boundary of the workplace, the emergency plan should also address managing the off-site effects. Where off-site effects are a possibility, the plan should provide for providing necessary warnings or communications to neighbouring workplaces.

5.81 Where emergency plans include agreements with the employers of neighbouring workplaces to provide mutual aid in emergencies, these arrangements should be formalised along with consultation between the emergency services and other involved parties to determine the plans effectiveness.

5.82 Where the emergency plan includes activities that involve persons who reside or work adjacent to the workplace, the relevant parts of the plan should be communicated to those persons.

Implementation

5.83 The emergency plan should be tested when first devised and after each modification. Throughout the year, at suitable intervals, practice drills and simulated emergencies should involve all employees and emergency services. These drills should be focussed on familiarising anyone who would be involved in an accident related to the storage and handling of dangerous goods with the workplace procedures.

5.84 The emergency plan should be reviewed:

- within five years of its development;

- in intervals of no more than five years;

- if there is a change of risk on or off the workplace;

- when updated information becomes available; and

- a possible deficiency is identified.

5.85 Emergency plans are to be readily available in hard copy form, at all times. The location of the emergency plan is to be easily located for supervisors, employees and should be discussed with the emergency services authority when it is updated or reviewed.

Emergency equipment

5.86 Equipment required to contain and clean up incidents will vary depending on the type and quantities of dangerous goods at the workplace.

5.87 Equipment should be located so it is readily accessible for all persons if, an emergency arises.

5.88 If safety equipment is needed to control a risk, the employer must make sure it is available and it should be regularly maintained and checked to ensure it operates effectively in accordance with the manufacturer’s specifications.

5.89 Safety equipment for use with dangerous goods must be compatible with the dangerous goods they may come in contact with.

5.90 Examples of emergency equipment

- over packs such as oversized drums for containing leaking containers;

- absorbent material suitable for the substances likely to be spilled;

- booms, plates and/or flexible sheeting for preventing spillage from entering drains and waterways;

- neutralising agents such as lime and soda ash;

- suitable pumps and hoses for removing spilled material;

- hand tools such as mops, buckets, squeegees and bins; and

- suitable protective clothing and equipment to protect the safety and health of personnel involved in the clean up.

5.91 An ignition source is any source of energy that can ignite a flammable atmosphere. Regulation 8.28 requires the elimination of ignition sources in hazardous areas of the workplace. Within a dangerous goods storage and handling environment, flammable or combustible gases, vapours, dusts and mists may be generated or evolve. These can form explosive mixtures with air in certain proportions.

5.92 Ignition sources should be identified and controlled. An employer must ensure that there are no ignition sources in a hazardous area. If it is not practicable to remove an ignition source, any risk from the ignition source must be reduced as far as practicable.

5.93 An employer should not permit the use of a flame or any other source of ignition during repairs on or adjacent to, a hazardous area unless:

- close and experienced supervision is provided during the activities;

- the area where the repair work is to be carried out has been freed of possible hazards, including toxic or flammable gases and vapours, and combustible dusts;

- personnel involved in the operation are given precise, detailed instructions on the precautions which are to be taken before and while the ignition sources are in the area; and

- additional controls are in place to ensure a dangerous situation does not arise, such as atmospheric monitoring, isolation of switches, pipe work and valves.

5.94 For work involving ignition sources in a hazardous area, a formal work permit system is recommended. This permit is usually referred to as a ‘hot work permit’.

5.95 In all hazardous areas, appropriate measures must be taken to eliminate the generation of static electricity and to safely dissipate any static electricity that does occur from any source.

5.96 Static electricity is generated by a wide variety of sources including:

- movement of dry powders and liquids that have a low electrical conductivity such as pouring, pumping, stirring, or high velocity flow;

- moving vehicles, equipment or components of plant;

- movements of personnel, especially when wearing clothing and footwear of low conductivity;

- fitting or removal of clothing, including protective clothing;

- application or removal of plastic wrap;

- particulate or aerosol spray, including spray painting or the rapid discharge of a carbon dioxide extinguisher;

- manual carrying of liquids in a non-conductive container or one with an insulating handle; and

- movement of packages by conveyor or by trolleys with non-conductive wheels.

5.97 The following examples should be considered by employers to eliminate the generation of static electricity in all hazardous areas:

- all tanks, pipe work, transfer systems and process plant should be earthed, or otherwise protected;

- liquid transfer rates and splashing should be minimised;

- the use of anti-static additives in non-conductive liquids, and to the wearing of conductive clothing, particularly footwear; and

- operating procedures should include instructions for avoiding the risks associated with static electricity.

5.98 Examples of an ignition source

- naked flames associated with blow torches, shrink wrapping equipment, stoves, gas or oil heaters, pilot lights, driers, lighters and matches;

- incandescent materials such as glowing coals or lighted cigarettes, cigars and pipes;

- arcs from electric welding or arcing contacts on electric motors and switchgear;

- static sparks;

- mechanical sparks from grinding or from objects striking together;

- friction from moving parts such as fan blades rubbing nearby surfaces;

- heat which may be generated from appliances or from chemical and biological reaction vessels;

- internal combustion engines and vehicles;

- radio transmitters and mobile phones; and

- electrical fittings and equipment (including wiring, power points, switches, lighting, appliances and battery forklift trucks) which are not rated for safe operation in the hazardous area.

5.99 Regulation 8.29 requires that safety equipment necessary for use with dangerous goods must be compatible with and suitably protected from, the dangerous goods with which it may come in contact. The equipment required to control risk should be determined through the risk assessment process.

5.100 The equipment must be available to relevant persons and maintained in accordance with manufacturers specifications.

5.101 Regulation 8.30 requires that an employer must ensure that any risk to a person’s health and safety associated with any atmospheric conditions is eliminated or if this is not practicable reduced.

5.102 Where the possibility of a hazardous atmosphere has been identified by the risk assessment process, atmospheric testing and monitoring must be carried out to ensure a safe atmosphere is maintained. A hazardous atmosphere is:

- not a safe oxygen level for breathing;

- concentrations of hazardous gases, vapours, mists, fumes and dusts are at or above relevant exposure standards; and

- concentration of flammable gases, vapours, mists, fumes and dusts is at or above five per cent of the lower explosion limit.

5.103 The control of risk arising from a hazardous atmosphere may be achieved by:

- preventing the entry of contaminants into the atmosphere using totally enclosed systems, or by blanketing an exposed surface with an inert atmosphere;

- extracting the contaminants from their sources through extraction ventilation;

- reducing the concentrations of contaminants by introducing uncontaminated air, either through general ventilation or by purging;

- limiting the introduction of processes and equipment into the area where the hazardous atmosphere may exist to those which will not constitute a risk in that atmosphere;

- ensuring appropriate personal protective clothing and equipment is worn by all personnel entering the area; and

- a combination of any of the above.

Ventilation Considerations

5.104 Local exhaust ventilation from each significant source of contamination is usually a more effective means of preventing build-up of a harmful atmosphere than an increase in general ventilation.

5.105 Where a storage area for closed containers of dangerous goods has adequate openings to the open air, natural ventilation may be sufficient. In other circumstances, a mechanical ventilation system may be required.

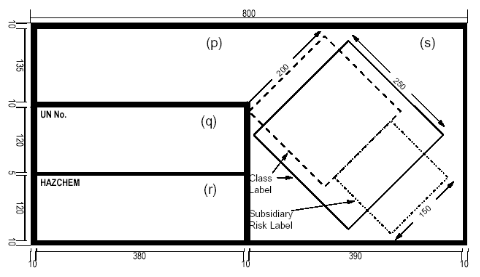

5.106 General ventilation should provide enough entry and exhaust capacity to provide airflow throughout the area, and to prevent pockets of harmful atmosphere from developing.