Schedule 1 Amendments

(regulation 3)

[1] Regulation 2.02, definition of boiler

omit

[2] Regulation 2.02, definition of National Standard

substitute

NOHSC: 1006 (2001) means the National Occupational Health and Safety Certification Standard for Users and Operators of Industrial Equipment (NOHSC: 1006 (2001)).

Note NOHSC: 1006 (2001) can be found on the Internet at www.nohsc.gov.au/PDF/Standards/NOHSC-1006-2001_STANDARD.pdf.

[3] Paragraph 2.03 (b)

omit

the National Standard.

insert

NOHSC: 1006 (2001).

[4] Regulation 2.04, note

substitute

Note The States and Territories that implement NOHSC: 1006 (2001) will issue certificates that comply with clause 5.4 of that Standard.

[5] Subregulation 2.07 (3), note 2

substitute

Note 2 Employers can use the translation tables in the Equivalence and Translation Tables to determine:

(a) the classes of occupational health and safety certificates of competency that were issued by State and Territory certifying authorities before the implementation of NOHSC: 1006 (2001); and

(b) the translation of those classes to classes in NOHSC: 1006 (2001).

[6] Paragraph 2.11 (1) (b)

omit

the National Standard;

insert

NOHSC: 1006 (2001);

[7] Regulation 4.03

omit

[8] Regulation 4.55

substitute

4.55 Definitions for Subdivision B

In this Subdivision:

licensee means the defence employing authority, as the holder of a special licence.

special licence means a licence granted under subregulation 4.58 (1) or renewed under subregulation 4.58 (2).

[9] Subregulation 6.02 (3)

substitute

(3) This Part does not apply to the following substances if the substances are used in circumstances that are not related to carrying out a work process:

(a) personal use products;

(b) food within the meaning of the Food Standards Australia New Zealand Act 1991.

[10] Regulation 6.03, definitions of ADG Code, asbestos, consumer package, ingredient, MSDS, retailer and use

omit

[11] Part 8

substitute

Part 8 Storage and handling of dangerous goods

Division 8.1 Introduction

8.01 Objects of Part 8

The object of this Part is to protect the health and safety of persons from hazards arising from the storage and handling of dangerous goods at a workplace by:

(a) ensuring that:

(i) hazards associated with the storage and handling of dangerous goods are identified; and

(ii) risks resulting from the hazards are assessed and controlled; and

(b) ensuring that the hazards are eliminated, or, if that is not reasonably practicable, the risks arising from the hazards are reduced, as far as practicable; and

(c) requiring the provision of relevant information and training; and

(d) ensuring that Comcare is notified if:

(i) dangerous goods are stored or handled in quantities that exceed the manifest quantities for the dangerous goods mentioned in Schedule 7; or

(ii) a pipeline is to be used for the transport of dangerous goods; and

(e) ensuring that emergency services and Comcare have access to relevant information concerning dangerous goods.

Note For the definition of dangerous goods, see subregulation 8.04 (3).

8.02 Application of Part 8

(1) Subject to subregulation (2), this Part applies to:

(a) the storage and handling, at a workplace, of dangerous goods; and

(b) a pipeline for the transport of dangerous goods.

(2) This Part does not apply to:

(a) goods, stored or handled at a workplace, that a relevant Competent Authority determines are not dangerous goods; or

(b) dangerous goods that are being transported in accordance with:

(i) the ADG Code; or

(ii) the Technical Instructions for the Safe Transport of Dangerous Goods by Air, published by the International Civil Aviation Organization, as in force on 1 May 2006; or

(iii) the International Maritime Dangerous Goods Code, published by the International Maritime Organisation, as in force on 1 May 2006; or

(iv) the Dangerous Goods Regulations, published by the International Air Transport Association, as in force on 1 May 2006; or

(c) dangerous goods that:

(i) are necessary for the propulsion of a vehicle, ship or other mobile plant, appliance or device; or

(ii) are in the propulsion system of the vehicle, ship or other mobile plant, appliance or device; or

(d) dangerous goods that:

(i) are part of, or are necessary for the operation of, the equipment or accessories of a vehicle, ship or other mobile plant, appliance or device; or

(ii) are in the operating system for the equipment or accessories; or

(e) dangerous goods in any of the following Classes:

(i) Class 1 (Explosives);

(ii) Subclass 6.2 (Infectious substances);

(iii) Class 7 (Radioactive material); or

(f) asbestos.

Note 1 Division 1 of Part 2 of the Act imposes general duties on employers, employees, manufacturers, suppliers and persons erecting or installing plant in a workplace.

Note 2 The Technical Instructions for the Safe Transport of Dangerous Goods by Air can be purchased from the International Civil Aviation Organization — see www.icao.int/.

Note 3 The International Maritime Dangerous Goods Code can be purchased from the International Maritime Organization — see www.imo.org/home.asp.

Note 4 The Dangerous Goods Regulations can be purchased from the International Air Transport Association — see www.iata.org/index.htm.

(3) This Part applies to a contractor of an employer, supplier or manufacturer in the same way that it applies to the employer, supplier or manufacturer.

8.03 Substances with unknown physical properties

(1) A person may supply a substance, the physical properties of which are unknown, only for the purposes of bona fide research.

(2) A person who supplies a substance in accordance with subregulation (1) is exempt from the requirements of Divisions 8.2 to 8.5 of this Part in relation to the substance only while the physical properties of the substance are unknown.

(3) In this regulation:

bona fide research means a systematic, investigative or experimental activity conducted for the purpose of:

(a) acquiring new knowledge; or

(b) creating new or improved materials, products, devices, processes or services; or

(c) analysis to identify the kind or quantities of ingredients in a substance.

substance:

(a) includes a chemical entity, composite material, mixture or formulation; and

(b) does not include an article.

Note 1 A person to whom this regulation applies continues to owe a general duty of care in relation to the safe manufacture and development of a substance mentioned in this regulation — see section 18 of the Act.

Note 2 A defendant bears an evidential burden in relation to the matter mentioned in regulation 8.03 (see section 13.3 of the Criminal Code).

8.04 Definitions for Part 8

(1) In this Part:

AS 1940-2004 means AS 1940-2004 ‘The storage and handling of flammable and combustible liquids’.

Note AS 1940-2004 is available for purchase from SAI Global Limited – see www.saiglobal.com.au.

bulk means:

(a) for dangerous goods other than solid dangerous goods — a quantity of the dangerous goods in a bulk container; or

(b) for solid dangerous goods not in a container — more than an undivided quantity of 400 kg of the dangerous goods.

bulk container means:

(a) for dangerous goods, other than combustible liquids:

(i) for Class 2 dangerous goods — a container with a capacity greater than 500 L; or

(ii) for dangerous goods, other than Class 2 dangerous goods — a container with a capacity greater than 450 L and a net mass, when full, of at least 400 kg; or

(b) for combustible liquids — a container with a capacity greater than 450 L.

bulk storage container means a bulk container at a workplace that is intended to remain in one place and is for use for the storage of dangerous goods at the workplace.

C1 combustible liquid means a combustible liquid with a flashpoint of more than 60.5C but not more than 150C.

C2 combustible liquid means a combustible liquid with a flashpoint of more than 150C.

capacity, of a container, means the total internal volume of the container at 15C expressed in litres or cubic metres.

Class, for dangerous goods, means a Class of dangerous goods mentioned in regulation 8.05.

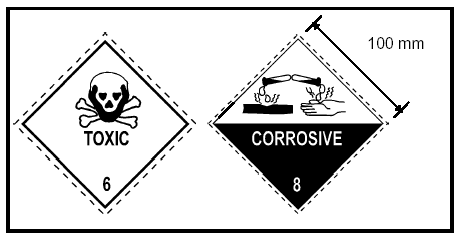

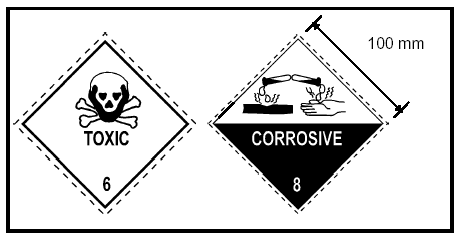

Class label means a label mentioned in Chapter 7 of the ADG Code for a Class.

combustible liquid has the meaning given by AS 1940-2004.

Note On 1 May 2006, combustible liquid was defined in AS 1940-2004 as follows:

‘Any liquid, other than a flammable liquid, that has a flash point, and has a fire point less than its boiling point.’

‘NOTES:

1 The boiling point is that point at which it is no longer possible to achieve the rate of temperature rise required by ISO 2592 for the determination of fire point.

2 ISO 2592, IP 36 and ASTM D92 are technically equivalent test methods for the determination of flash and fire point by Cleveland open cup tester.’

compatible, for a substance, has the meaning given by subregulation (2).

Competent Authority means:

(a) for the Commonwealth — a Competent Authority within the meaning of section 6 of the Road Transport Reform (Dangerous Goods) Act 1995; and

(b) for New South Wales — a Competent Authority within the meaning of section 6 of the Road and Rail Transport (Dangerous Goods) Act 1997 (NSW) as in force on 1 May 2006; and

(c) for Victoria — a Competent Authority within the meaning of the Road Transport (Dangerous Goods) Act 1995 (Vic) as in force on 1 May 2006; and

(d) for Queensland — the chief executive mentioned in regulation 13 of the Transport Operations (Road Use Management — Dangerous Goods) Regulations 1998 (Qld) as in force on 1 May 2006; and

(e) for Western Australia — a Competent Authority within the meaning of section 3 of the Dangerous Goods (Transport) Act 1998 (WA) as in force on 1 May 2006; and

(f) for South Australia — a Competent Authority within the meaning of the Dangerous Substances Act 1979 (SA) as in force on 1 May 2006; and

(g) for Tasmania — a Competent Authority within the meaning of section 3 of the Dangerous Goods Act 1998 (Tas) as in force on 1 May 2006; and

(h) for the Northern Territory — the Minister mentioned in section 13 of the Dangerous Goods Act 1980 (NT) as in force on 1 May 2006.

container means a thing by, or in, which dangerous goods are wholly or partly contained, and includes any components or materials necessary for the thing’s containment function to be carried out.

control temperature, for dangerous goods, means the maximum temperature, mentioned in the ADG Code, at which the dangerous goods can be safely stored and handled.

dangerous goods has the meaning given by subregulation (3).

dangerous goods in transit has the meaning given by subregulation (5).

dangerous occurrence has the meaning given by regulation 3 of the Occupational Health and Safety (Commonwealth Employment) Regulations 1991.

fire risk dangerous goods means dangerous goods of Class 2.1, 3, 4 or 5, or Subsidiary Risk 2.1, 3, 4 or 5, that burn readily or support combustion.

free from dangerous goods, for an object, has the meaning given by subregulation (6).

goods too dangerous to be transported means goods that:

(a) are named in Appendix 5 to the ADG Code; or

(b) are determined by a relevant Competent Authority to be goods too dangerous to be transported.

handling, for dangerous goods, includes:

(a) moving the dangerous goods within a workplace or within a pipework or pipeline; and

(b) manufacturing, processing, using, treating, dispensing, packing, supplying, transferring, loading and unloading, making harmless, destroying and disposing of the dangerous goods.

hazardous area has the meaning given by AS/NZS 2430.3.1:2004 ‘Classification of hazardous areas — General’.

Note 1 On 1 May 2006, hazardous area was defined in AS/NZS 2430.3.1:2004 as follows:

‘An area in which an explosive atmosphere is present, or may be expected to be present, in quantities such as to require special precautions for the construction, installation and use of potential ignition sources.

NOTES:

1 For the purpose of this Standard, an area is regarded as a three‑dimensional region or space.

2 Examples of potential ignition sources are electrical equipment, naked flames, sparks from grinding and welding operations, and hot surfaces.’

Note 2 AS/NZS 2430.3.1:2004 is available for purchase from SAI Global Limited – see www.saiglobal.com.au.

Hazchem code has the meaning given by clause 1.1.3 of the ADG Code.

Note On 1 May 2006, Hazchem code was defined in clause 1.1.3 of the ADG Code for a load of dangerous goods as ‘the Hazchem code derived for those goods under Appendix 4 of the ADG Code’.

ignition source means a source of energy sufficient to ignite a flammable atmosphere, including a naked flame, exposed incandescent material, an electrical welding arc, a mechanical or static spark, and electrical or mechanical equipment not specifically designed to be used in a flammable atmosphere.

intermediate bulk container means a rigid or flexible bulk packaging for the transport of dangerous goods, that:

(a) has a capacity of not more than:

(i) for a composite, fibreboard, flexible, rigid plastic or wooden container for transporting a solid of Packing Group I — 1 500 L; and

(ii) for a metal container for transporting a solid of Packing Group I — 3 000 L; and

(iii) for a container for transporting a solid or liquid of Packing Group II or III — 3 000 L; and

(b) is designed for mechanical handling; and

(c) is resistant to the stresses produced in usual handling and transport.

near miss means an unplanned occurrence, involving imminent risk, that, but for a mitigating effect, action or system, could have become a dangerous occurrence.

package means dangerous goods and their packaging.

packaged dangerous goods means dangerous goods in a container that has:

(a) for dangerous goods, other than combustible liquids:

(i) for Class 2 dangerous goods — a capacity of up to 500 L; or

(ii) for dangerous goods, other than Class 2 dangerous goods — a capacity of up to 450 L and a net mass, when full, of up to 400 kg; or

(b) for combustible liquids — a capacity of up to 450 L.

packaging means a container in which dangerous goods are received or held, and includes anything that allows the container to receive or hold the dangerous goods, or to be closed.

packing group, of dangerous goods, is a reference to the packing group to which the dangerous goods are assigned under subregulation (7).

pipeline means pipework that:

(a) begins or ends in a workplace at the nearest fluid or slurry control point (along the axis of the pipeline) to the boundary of the workplace; and

(b) crosses the boundary of a Commonwealth workplace.

pipework means a pipe, or an assembly of pipes, pipe fittings, valves and pipe accessories, used to transport dangerous goods within or outside a workplace.

product name, for dangerous goods, means the brand name or trade name given to the dangerous goods by the supplier of the dangerous goods.

proper shipping name has the meaning given by clause 1.1.3 of the ADG Code.

Note On 1 May 2006, clause 1.1.3 of the ADG Code defined proper shipping name as having the meaning given in clause 2.2.1 of that Code.

protected place means any of the following:

(a) a dwelling, place of worship, public building, school or college, hospital, child-care facility or theatre;

(b) a factory, workshop, office, store, warehouse, shop, building or yard in which people who are not directly involved with the storage and handling of dangerous goods are working;

(c) a ship lying in a permanent berthing facility.

relevant Competent Authority, for an employer, means:

(a) a Competent Authority within the meaning of section 6 of the Road Transport Reform (Dangerous Goods) Act 1995; and

(b) a Competent Authority in the State or Territory in which the employer operates.

Subsidiary Risk, of dangerous goods, is a reference to the Subsidiary Risk to which the dangerous goods are assigned under subregulation (8).

Subsidiary Risk label means a label mentioned in Chapter 7 of the ADG Code for a particular Subsidiary Risk.

tank means a bulk container, other than an intermediate bulk container, that is used or is designed to be used to transport, store or handle dangerous goods in the form of a gas or a liquid in bulk, and includes any equipment that forms part of the container.

transfer, in relation to dangerous goods, means move the dangerous goods from one container to another, or from one place to another, and includes pumping, dispensing or decanting the dangerous goods.

underground tank means a tank that is wholly or partly buried in a place in the ground and is intended to remain in that place.

UN number, for dangerous goods, means:

(a) the substance identification number shown in Column 1 of Appendix 1 to the ADG Code for the dangerous goods; or

(b) the number assigned to the dangerous goods by the UN Committee of Experts in the Transport of Dangerous Goods, published in the United Nations Recommendations on the Transport of Dangerous Goods.

Note The United Nations Recommendations on the Transport of Dangerous Goods are available on the internet at www.unece.org/trans/danger/publi/unrec/mr_nature_e.html.

(2) Two or more substances are compatible if the substances will not react together to:

(a) cause a fire, explosion, harmful reaction or the evolution of flammable, corrosive or toxic vapours; or

(b) cause a dangerous occurrence; or

(c) substantially increase the potential of the combined substances to cause a dangerous occurrence.

(3) Dangerous goods are goods that:

(a) are named in column 2 of Appendix 2 to the ADG Code; or

(b) meet the criteria in Chapter 2 of the ADG Code; or

(c) are determined by a relevant Competent Authority to be dangerous goods; or

(d) are C1 combustible liquids; or

(e) are C2 combustible liquids, if stored and handled with fire risk dangerous goods (within the meaning of subregulation (4)); or

(f) are goods too dangerous to be transported.

Note On 1 May 2006, the definition of ‘dangerous goods’ in the ADG Code did not include C1 and C2 combustible liquids.

(4) C2 combustible liquids are stored and handled with fire risk dangerous goods if the storage and handling of the C2 combustible liquids are not separated, by distance or barriers, from the storage and handling of fire risk dangerous goods so that if a reasonably foreseeable incident involving the C2 combustible liquids or the fire risk dangerous goods occurs, the C2 combustible liquids and the fire risk dangerous goods will come into contact.

(5) Dangerous goods in transit are dangerous goods that:

(a) are supplied to a workplace in a container that is not opened at the workplace; and

(b) are not used at the workplace; and

(c) are kept at the workplace for no more than 5 consecutive days.

(6) An object is free from dangerous goods if:

(a) for an object that last held a gas or volatile liquid — the concentration of gas or vapour in the atmosphere of the object is less than the concentration mentioned in the National Exposure Standards for Atmospheric Contaminants in the Occupational Environment [NOHSC:3008 (1995)]; or

(b) for an object that last held dangerous goods of Class 2.1 or 3 or of Subsidiary Risk 3 — the concentration of those dangerous goods or their vapours in the atmosphere of the object is less than 5% of the lower explosive limit for the dangerous goods when sampled at ambient temperature; or

(c) for an object that last held a non-volatile liquid or solid — the object has been thoroughly cleaned.

Note NOHSC:3008 (1995) is available on the NOHSC website, www.nohsc.gov.au/OHSInformation/NOHSCPublications/#1.

(7) Dangerous goods are assigned to a packing group if the dangerous goods:

(a) are assigned to the packing group in column 5 of Appendix 2 to the ADG Code; or

(b) are assigned to the packing group in a Special Provision of the ADG Code applying to the dangerous goods; or

(c) satisfy the criteria in column 9 of Appendix 2 to the ADG Code for assignment to the packing group; or

(d) are determined by a relevant Competent Authority to be assigned to the packing group.

(8) Dangerous goods are assigned a Subsidiary Risk if the dangerous goods:

(a) are assigned the Subsidiary Risk in column 4 in Appendix 2 to the ADG Code; or

(b) are assigned the Subsidiary Risk in a Special Provision of the ADG Code applying to the dangerous goods; or

(c) satisfy the criteria in column 9 in Appendix 2 to the ADG Code for assignment of the Subsidiary Risk; or

(d) are determined by a relevant Competent Authority to be dangerous goods assigned the Subsidiary Risk.

Note Part 10 also contains definitions of terms that are used in this Part.

8.05 Classes of dangerous goods

The Classes of dangerous goods are set out in the following table.

Note Dangerous goods are classified according to the most significant risk presented by the dangerous goods, determined in accordance with the criteria set out in Chapter 2 of the ADG Code.

Item | Class | Subclass | Description of dangerous goods and subclasses (if any) |

1 | 1 | | Explosives |

2 | 2 | | Gases |

3 | | 2.1 | Flammable gases |

4 | | 2.2 | Non-flammable, non-toxic gases |

5 | | 2.3 | Toxic gases |

6 | 3 | | Flammable liquids |

7 | 4 | | Flammable solids, substances liable to spontaneous combustion and substances that in contact with water emit flammable gases |

8 | | 4.1 | Flammable solids |

9 | | 4.2 | Substances liable to spontaneous combustion |

10 | | 4.3 | Substances that in contact with water emit flammable gases |

11 | 5 | | Oxidizing substances and organic peroxides |

12 | | 5.1 | Oxidizing substances |

13 | | 5.2 | Organic peroxides |

14 | 6 | | Toxic and infectious substances |

15 | | 6.1 | Toxic substances |

16 | | 6.2 | Infectious substances |

17 | 7 | | Radioactive material |

18 | 8 | | Corrosive substances |

19 | 9 | | Miscellaneous substances and articles |

8.06 Inconsistency between this Part and codes etc

(1) In this regulation:

instrument means a code, standard or rule (made in or outside Australia) about the storage and handling of dangerous goods.

(2) If an instrument is applied or adopted by, or is incorporated in, this Part and the instrument is inconsistent with this Part, this Part prevails to the extent of the inconsistency.

8.07 Determinations in relation to dangerous goods taken to be regulations

(1) A determination, as in force on 1 May 2006, by the Competent Authority under regulation 1.18 of the Road Transport Reform (Dangerous Goods) Regulations 1997 is taken to be a regulation under this Part.

(2) A determination, as in force on 1 May 2006, by a Competent Authority under the following legislation is taken to be a regulation under this Part:

(a) the Road Transport Reform (Dangerous Goods) Regulations 1997, applied as regulations by the Road and Rail Transport (Dangerous Goods) (Road) Regulation 1998 (NSW) as in force on 1 May 2006;

(b) the regulations in force under Part 2 of the Road Transport Reform (Dangerous Goods) Act 1995 applied as a law of Victoria under the Road Transport (Dangerous Goods) Act 1995 (Vic) as in force on 1 May 2006;

(c) the Dangerous Goods (Transport) (General) Regulations 1999 (WA) as in force on 1 May 2006;

(d) the Road Transport Reform (Dangerous Goods) (South Australia) Regulations 1998 (SA) as in force on 1 May 2006;

(e) the Dangerous Goods (Road and Rail Transport) Regulations 1998 (Tas) as in force on 1 May 2006.

Note For the Road Transport Reform (Dangerous Goods) (South Australia) Regulations 1998 (SA), see regulation 10 of the Dangerous Substances Regulations 2002 (SA).

(3) A determination, as in force on 1 May 2006, by the chief executive under section 13 of the Transport Operations (Road Use Management — Dangerous Goods) Regulation 1998 (Qld) as in force on 1 May 2006, is taken to be a regulation under this Part.

(4) A declaration by the Minister, as in force on 1 May 2006, under section 13 of the Dangerous Goods Act (NT) as in force on 1 May 2006, is taken to be a regulation under this Part.

8.08 Quantities of dangerous goods

For this Part:

(a) a reference to a quantity of packaged dangerous goods or combustible liquids is taken to be a reference to:

(i) for non-liquid dangerous goods (other than Class 2 dangerous goods) — the net mass in kilograms of the dangerous goods in the container; and

(ii) for liquid dangerous goods (other than Class 2 dangerous goods) or combustible liquids — the net capacity of the container; and

(iii) for Class 2 dangerous goods — the total capacity of the container; and

(b) a reference to a quantity of dangerous goods or combustible liquids in bulk, being dangerous goods or combustible liquids held in a tank, is taken to be a reference to:

(i) for dangerous goods (other than Class 2 dangerous goods) or combustible liquids — the net mass in kilograms that the tank is designed to hold; and

(ii) for Class 2 dangerous goods — the total capacity of the tank; and

(c) a reference to a quantity of any other dangerous goods is taken to be a reference to the net quantity of the dangerous goods that is dangerous goods.

Division 8.2 Duties of manufacturers, suppliers and installers

Note The effect of subsection 18 (3) of the Act is that a person who imports into Australia a substance that the person has not manufactured must, if the person does not have a place of business in Australia at the time of the importation, be taken to be the manufacturer of the substance.

Subdivision 8.2.1 Duties of manufacturers of dangerous goods

8.09 Determination whether goods are dangerous goods

(1) A manufacturer of goods commits an offence if the manufacturer:

(a) is reckless with respect to whether the goods will be used by employees at a workplace; and

(b) does not, in writing and as soon as practicable after beginning to manufacture the goods, determine whether the goods are dangerous goods.

Penalty: 10 penalty units.

(2) A determination under subregulation (1) must be made in accordance with:

(a) for goods other than liquids — the criteria in Chapter 2 of the ADG Code; and

(b) for liquids — AS 1940-2004.

Penalty: 10 penalty units.

(3) Strict liability applies to the physical element in subregulation (2) that the goods are dangerous goods in accordance with the ADG Code or AS 1940-2004.

(4) The manufacturer must keep the determination, or a copy of the determination, for the period during which the manufacturer manufactures the goods.

Penalty: 5 penalty units.

(5) An offence against subregulation (4) is an offence of strict liability.

(6) A manufacturer who manufactures dangerous goods must ensure that the dangerous goods are classified:

(a) for dangerous goods listed in Appendix 2 of the ADG Code — in accordance with the ADG Code; or

(b) for any other dangerous goods — in accordance with the criteria in Chapter 2 of the ADG Code.

Penalty: 10 penalty units.

(7) Strict liability applies to the physical element in subregulation (6) that the dangerous goods are classified in accordance with the ADG Code.

8.10 Material Safety Data Sheets

(1) Subject to subregulations (2) and (4), a manufacturer of dangerous goods commits an offence if the manufacturer:

(a) is reckless with respect to whether the dangerous goods will be used by employees at a workplace; and

(b) does not prepare an MSDS for the dangerous goods before the dangerous goods are supplied to the employer of the employees.

Penalty: 10 penalty units.

Note 1 The purpose of an MSDS is to provide the information needed to allow the safe storage and handling of dangerous goods used at a workplace. The MSDS for particular dangerous goods describes its identity, relevant health hazard information, precautions for use and safe storage and handling information.

Note 2 Guidance on the preparation and use of an MSDS can be obtained from the National Code of Practice for the Preparation of Material Safety Data Sheets [NOHSC:2011 (2003)]. The National Code of Practice is available on the Internet at www.nohsc.gov.au/default.asp.

(2) An MSDS must be prepared in accordance with the National Code of Practice for the Preparation of Material Safety Data Sheets [NOHSC:2011 (2003)].

Note The National Code of Practice for the Preparation of Material Safety Data Sheets [NOHSC:2011 (2003)] is available on the Internet at www.nohsc.gov.au/default.asp.

(3) Subject to subregulation (4), a manufacturer of dangerous goods commits an offence if the manufacturer:

(a) is reckless with respect to whether the dangerous goods will be used by employees at a workplace; and

(b) does not give a copy of the current MSDS for the dangerous goods to a supplier who supplies the dangerous goods to the employer of the employees:

(i) before the dangerous goods are first supplied by the supplier to the employer; and

(ii) at any later time on request by the supplier.

Penalty: 10 penalty units.

(4) Subregulations (1), (2) and (3) do not apply to the supply of C1 combustible liquids or C2 combustible liquids.

(5) The manufacturer must:

(a) review an MSDS:

(i) within 5 years after the MSDS is first issued, and afterwards at intervals of not more than 5 years; and

(ii) as often as is necessary to ensure that the MSDS contains current information and is accurate in all significant details; and

(b) if the MSDS does not contain current information or is not accurate in all significant details — revise the MSDS so that it contains current information and is accurate in all significant details.

Penalty: 10 penalty units.

(6) The MSDS must include the name of each ingredient of the dangerous goods.

(7) If the identity of an ingredient of the dangerous goods is commercially confidential, the manufacturer may use the generic name for the ingredient in the MSDS.

(8) However, if:

(a) the manufacturer considers that giving the generic name of the ingredient would cause commercial disadvantage; and

(b) the ingredient is not dangerous goods; and

(c) the ingredient does not have a known synergistic effect;

the manufacturer may include a statement in the MSDS to the effect that the ingredient is an ingredient determined not to be dangerous goods.

(9) Despite subregulations (7) and (8), if there is a medical emergency involving the dangerous goods, the manufacturer must disclose the name of the ingredient.

Note Regulation 6.05 provides for manufacturer’s duties in relation to MSDS for hazardous substances.

Subdivision 8.2.2 Duties of suppliers of dangerous goods

8.11 Containment, packaging and labelling of dangerous goods

(1) A manufacturer of dangerous goods commits an offence if the manufacturer:

(a) supplies dangerous goods; and

(b) is reckless with respect to whether the dangerous goods will be used by employees at a workplace; and

(c) does not ensure that the dangerous goods:

(i) are contained, packaged and labelled in accordance with the ADG Code; and

(ii) are labelled with any other information that is necessary to protect the health and safety of employees.

Penalty: 10 penalty units.

Note Chapter 3 of the ADG Code deals with containment, packaging and labelling requirements.

(2) A person who is not a manufacturer of dangerous goods commits an offence if the person:

(a) supplies dangerous goods; and

(b) is reckless with respect to whether the dangerous goods will be used by employees at a workplace; and

(c) does not ensure that the dangerous goods are contained, packaged and labelled in accordance with subregulation (1).

Penalty: 10 penalty units.

(3) Subregulation (2) does not apply to a retailer in relation to the supply of packaged dangerous goods in a container provided by the purchaser if the retailer ensures that, as far as practicable, the container:

(a) is of a material that will not react adversely with the dangerous goods; and

(b) is constructed in a manner that will contain the dangerous goods; and

(c) is not damaged; and

(d) is clearly marked with the name of the dangerous goods; and

(e) cannot be mistakenly identified as containing foodstuffs.

(4) Strict liability applies to the physical element in subregulation (2) that the dangerous goods are contained, packaged and labelled in accordance with subregulation (1).

(5) A person commits an offence if the person:

(a) fills, allows to be filled or causes to be filled with Class 2 dangerous goods a cylinder, disposable container or aerosol container; and

(b) is reckless with respect to whether the dangerous goods will be used by employees at a workplace; and

(c) does not ensure that the cylinder or container complies with the ADG Code.

Penalty: 10 penalty units.

Note Paragraph 3.8.2 and Appendix 2 of the ADG Code deal with containers and cylinders for Class 2 dangerous goods.

8.12 Material Safety Data Sheets

(1) A supplier of dangerous goods commits an offence if the supplier:

(a) supplies dangerous goods to an employer; and

(b) is reckless with respect to whether the dangerous goods will be used by employees at a workplace; and

(c) does not give a copy of the current MSDS for the dangerous goods to the employer for the workplace:

(i) the first time the dangerous goods are supplied to the employer; and

(ii) at any later time, if the employer asks the supplier for the current MSDS for the dangerous goods.

Penalty: 10 penalty units.

(2) This regulation does not apply in relation to the supply by a retailer to a purchaser of packaged dangerous goods that are consumer packages.

8.13 Additional information

(1) A person who receives dangerous goods from a supplier may ask the supplier for information that is:

(a) relevant to the safe storage and handling of the dangerous goods; and

(b) not contained in the MSDS for the dangerous goods.

(2) A supplier who receives a request under subregulation (1) must give the information to the person, if the information that is available to the supplier at the time the request is received:

(a) relates to the storage and handling of the dangerous goods; and

(b) is additional to the information contained in the MSDS for the dangerous goods.

Penalty: 10 penalty units.

Subdivision 8.2.3 Duties of suppliers or installers of plant or structures

8.14 Supply or installation of plant or structures

(1) A person who supplies or installs plant or a structure commits an offence if the person:

(a) is reckless with respect to whether the plant or structure will be used by employees at a workplace for the storage or handling of dangerous goods; and

(b) does not ensure that:

(i) the plant or structure is suitable for use, and able to be used safely, with the dangerous goods; and

(ii) the plant or structure conforms with the design for that plant or structure; and

(iii) if the plant or a structure is designed to be operated in a fixed position — unintentional movement of the plant or structure is prevented; and

(iv) the employer is given information:

(A) relating to the installation, testing, commissioning, use, inspection, maintenance, repair, decommissioning and disposal of the plant or structure, to the extent that this is necessary for the plant or structure to be used for its intended purposes; and

(B) explaining how the plant or structure should be operated and maintained; and

(C) stating any conditions or specifications that must be complied with to ensure the safety and health of employees when the plant or structure is in operation.

Penalty: 10 penalty units.

(2) A person who has supplied or installed plant or a structure commits an offence if the person:

(a) is reckless with respect to whether the plant or structure will be used by employees at a workplace for the storage or handling of dangerous goods; and

(b) does not ensure that, as far as practicable, the employer is given any information that becomes available about the plant or structure that is relevant to its use for that purpose.

Penalty: 10 penalty units.

Division 8.3 Duties of employers

Subdivision 8.3.1 Hazard identification and risk assessment

Note Part 6 applies to hazardous substances (within the meaning of that Part). If goods that are dangerous goods are also a hazardous substance, both Part 6 and this Part must be complied with in relation to the goods.

8.15 Hazard identification

(1) An employer must ensure that any hazard associated with the storage or handling of dangerous goods at the workplace is identified, to the extent practicable having regard to the state of knowledge of the hazard.

Penalty: 10 penalty units.

(2) Without limiting subregulation (1), the employer must ensure that, in identifying a hazard, the following are considered:

(a) the chemical and physical properties of the dangerous goods, including physical state, viscosity, vapour pressure, chemical energy, particle size, solubility, electrical conductivity, reactivity, combustion products and concentration;

(b) the chemical and physical reaction between the dangerous goods and any things or substances with which the dangerous goods may come into contact at the workplace;

(c) any manufacturing, transfer or transport process at the workplace involving the dangerous goods, including:

(i) the temperatures and pressures to which the dangerous goods are subjected; and

(ii) physical processes (for example, separation, mixing and absorption); and

(iii) changes of state and processes involving chemical reaction;

(d) the structures, plant (including the characteristics of the materials used in the plant), systems of work and activities that are used in the storage or handling of the dangerous goods at the workplace;

(e) the structures, plant (including the characteristics of the materials used in the plant), systems of work and activities that are not used in the storage or handling of the dangerous goods at the workplace but that could interact with the dangerous goods at the workplace;

(f) any information about the hazardous properties inherent in the dangerous goods, including information in any MSDS for the dangerous goods available to the employer;

(g) the kind and characteristics of incidents associated with the dangerous goods, including incidents affecting the structures or plant used to store or handle the dangerous goods;

(h) the location of the dangerous goods at the workplace;

(i) the effects (if any) of environmental conditions (for example vegetation, moisture, rain, wind, pollution, flooding, lightning, heat and cold) on the dangerous goods.

(3) The employer must ensure that a record of each hazard identified is kept.

Penalty: 10 penalty units.

8.16 Risk assessment

(1) If a hazard associated with the storage or handling of dangerous goods at the workplace is identified under regulation 8.15, the employer must ensure that any risks associated with the hazard are assessed.

Penalty: 10 penalty units.

(2) Without limiting subregulation (1), the employer must ensure that, when a risk is being assessed, the following are considered:

(a) the matters mentioned in subregulation 8.15 (2);

(b) the consequences, within and outside the workplace, of any incident that could occur because of the storage or handling of the dangerous goods.

(3) The employer must ensure that the assessment is reviewed:

(a) within 5 years after the assessment is carried out, and afterwards at intervals of not more than 5 years; and

(b) as soon as practicable after any change in circumstances such that the assessment is no longer valid.

Penalty: 10 penalty units.

(4) The employer must ensure that:

(a) a record is kept of each assessment and review; and

(b) a copy of the record is kept while the assessment is current or being reviewed; and

(c) on request by Comcare, Comcare is given a copy of the record.

Penalty: 10 penalty units.

(5) An offence against subregulation (4) is an offence of strict liability.

Subdivision 8.3.2 Risk control

8.17 Control of risk

(1) An employer must ensure that any risk associated with the storage or handling of dangerous goods at a workplace is:

(a) eliminated; or

(b) if it is not practicable to eliminate the risk — reduced as far as practicable.

Penalty: 10 penalty units.

(2) Subject to subregulation (3), the employer must ensure that the risk is eliminated or reduced by:

(a) eliminating the use of the dangerous goods; or

(b) using other dangerous goods that have a lower risk than the original dangerous goods; or

(c) reducing, as far as practicable, the quantity of dangerous goods that are stored or handled at the workplace.

(3) If it is not practicable to reduce the risk in accordance with subregulation (2), the employer must ensure that appropriate engineering controls and systems of work are used to reduce the risk as far as practicable.

(4) The employer must ensure that:

(a) control measures and safe systems of work are implemented, commissioned, supervised, inspected and maintained at the workplace for the purpose of ensuring that the employer retains control over the use of the dangerous goods; and

(b) if any breaches of this Part occur:

(i) action is taken as soon as practicable to address the breach; and

(ii) if a risk results from the breach — the risk is eliminated or, if this is not practicable, the risk is reduced as far as practicable; and

(c) employees are provided with appropriate personal protective clothing and equipment.

Penalty: 10 penalty units.

(5) The employer must ensure that plant or a structure for the storage or handling of dangerous goods is designed, manufactured, installed, commissioned, operated, inspected, tested, maintained, repaired and decommissioned to eliminate any risks, or, if this is not practicable, to reduce any risks associated with the use of the plant or structure as far as practicable.

Penalty: 10 penalty units.

(6) The employer must ensure that the plant (including the characteristics of the materials used in the plant), structures, activities, systems of work, substances or things that are not used for storage or handling of dangerous goods at the workplace do not affect the dangerous goods or the way in which the dangerous goods are stored or handled so as to increase any risks associated with the dangerous goods.

Penalty: 10 penalty units.

(7) The employer must ensure that a risk mentioned in subregulation (8) is:

(a) eliminated; or

(b) if it is not reasonably practicable to eliminate the risk — reduced as far as practicable.

Penalty: 10 penalty units.

(8) The risks are:

(a) a risk to a person who is at or near a workplace under the employer’s control, and who is not an employee or contractor of the employer, that results from the storage or handling of dangerous goods at the workplace; and

(b) a risk to plant, structures, processes, activities and systems of work used for storage or handling of dangerous goods at a workplace under the employer’s control, that results from an action of a person who is not an employee or contractor of the employer and who has access to an area where dangerous goods are stored or handled.

8.18 Physical separation of dangerous goods from people, protected places and other property

An employer must ensure that any risk to:

(a) a person at or near the workplace; or

(b) a protected place or any other property at or outside the workplace;

resulting from a dangerous occurrence involving the storage or handling of dangerous goods at the workplace is eliminated, or, if this is not reasonably practicable, is reduced as far as practicable by separating the dangerous goods from the person, protected place or other property by distance or barriers, or both.

Penalty: 10 penalty units.

8.19 Separation of dangerous goods from incompatible substances

An employer must ensure that, as far as practicable, dangerous goods are stored or handled at the workplace in such a way as to prevent them:

(a) interacting with goods that are not compatible with the dangerous goods; or

(b) contaminating food, food packaging or personal use products.

Penalty: 10 penalty units.

8.20 Keeping dangerous goods stable etc

(1) An employer must ensure that, as far as practicable, dangerous goods that are stored or handled at the workplace do not accidentally become unstable, decompose or change in such a way that:

(a) the dangerous goods create a different hazard from the original hazard; or

(b) any risk associated with the dangerous goods is increased.

Penalty: 10 penalty units.

(2) Without limiting subregulation (1):

(a) if the stability of the dangerous goods depends on the maintenance of the proportions of the substances that constitute the dangerous goods, including any ingredient that stabilises the dangerous goods, the employer must ensure that the proportions are maintained in accordance with the manufacturer’s specifications; and

(b) if a control temperature is specified for the dangerous goods in the ADG Code, the employer must ensure that the dangerous goods are kept at that temperature; and

(c) if a control temperature is not specified for the dangerous goods in the ADG Code, the employer must ensure that the dangerous goods are kept at, below or above a temperature in accordance with the manufacturer’s specifications.

(3) Subregulations (1) and (2) do not apply in relation to dangerous goods that are about to be used in a manufacturing process.

8.21 Impact protection — structures and plant

An employer must ensure that a structure or plant used for storage or handling dangerous goods at the workplace, and any pipework or equipment attached to the structure or plant, are:

(a) appropriately located in the workplace; and

(b) if necessary, fixed to a stable foundation;

to prevent damage from movement of the structure or plant or any attached pipework or equipment.

Penalty: 10 penalty units.

8.22 Impact protection — containers

An employer must ensure that, as far as reasonably practicable, a container at the workplace in which dangerous goods are stored, and any pipework or equipment attached to the container, are protected from damage resulting from an activity conducted at the workplace.

Penalty: 10 penalty units.

8.23 Spills and containment of dangerous goods

If a spill, leak or accidental release of dangerous goods occurs at a workplace, the employer must ensure that:

(a) the spill, leak or release is confined, as far as practicable, within the workplace; and

(b) immediate action is taken to assess and control any risk resulting from the spill, leak or release; and

(c) the dangerous goods are contained, cleaned up, disposed of or otherwise made safe, as soon as practicable after the spill, leak or release.

Penalty: 10 penalty units.

8.24 Transfer of dangerous goods

An employer must ensure that any risk associated with the transfer of dangerous goods to, from, or within, the workplace, is eliminated, or, if this is not practicable, is reduced as far as practicable, having regard to the need to:

(a) avoid spillage or overflow; and

(b) reduce static electricity; and

(c) reduce vapour generation; and

(d) ensure that transfer fittings are compatible; and

(e) avoid sources of ignition; and

(f) ensure that associated plant and equipment is free from dangerous goods.

Penalty: 10 penalty units.

Note The expression free from dangerous goods is defined in subregulation 8.04 (6).

8.25 Fire protection

(1) An employer must ensure that:

(a) the workplace is provided with fire protection and fire fighting equipment that is designed and constructed for use in relation to the kinds and quantities of dangerous goods that are stored or handled at the workplace, and the conditions under which the dangerous goods are stored and handled at the workplace, having regard to:

(i) the fireload of the dangerous goods; and

(ii) the compatibility of the dangerous goods with other goods; and

(iii) things that may cause or exacerbate a fire involving the dangerous goods; and

(iv) other workplaces, premises or a protected place near the employer’s workplace; and

(b) the fire protection and fire fighting equipment are installed, tested and maintained in accordance with the manufacturer’s specifications.

Penalty: 10 penalty units.

Example for subparagraph (1) (a) (iii)

Things that could cause or exacerbate a fire involving dangerous goods include:

environmental conditions such as vegetation, moisture, rain, wind, pollution, flooding, lightning, heat and cold

vehicles

non-dangerous goods.

(2) If the fire protection or fire fighting equipment becomes ineffective, the employer must ensure that:

(a) any risk resulting from the loss of effective fire protection or fire fighting equipment is assessed as soon as practicable; and

(b) if necessary:

(i) alternative fire protection or fire fighting equipment is provided to maintain an appropriate level of protection; or

(ii) action is taken to eliminate, as far as practicable, any risk associated with the storage or handling of dangerous goods; or

(iii) action is taken, as soon as practicable, to ensure that the fire protection or fire fighting equipment is effective.

Penalty: 10 penalty units.

8.26 Emergency procedures

An employer must ensure that:

(a) a procedure for dealing with any emergency that may arise in connection with the storage or handling of dangerous goods at the workplace is:

(i) developed, implemented and maintained; and

(ii) communicated to relevant persons at the workplace who may be affected by, or who may respond to, an emergency; and

(b) appropriate equipment is available:

(i) for use in dealing with an emergency; and

(ii) for containing and cleaning up incidents that it is reasonable to foresee may occur in an emergency.

Penalty: 10 penalty units.

8.27 Emergency plans

(1) This regulation applies to an employer if:

(a) dangerous goods of a Class mentioned in column 2 of an item of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of the dangerous goods is more than the manifest quantity mentioned in column 5 of that item.

(2) The employer must ensure that:

(a) an emergency plan for dealing with any emergency that may arise in connection with the storage or handling of dangerous goods at the workplace is:

(i) developed, implemented and maintained; and

(ii) communicated to employees at the workplace who may be affected by, or who may respond to, an emergency; and

(b) appropriate equipment is available:

(i) for use in dealing with an emergency; and

(ii) for containing and cleaning up incidents that it is reasonable to foresee may occur in an emergency; and

(c) appropriate material, such as absorbents and neutralisers, is available for use in dealing with an emergency.

Penalty: 10 penalty units.

(3) The employer must ensure that the emergency plan mentioned in subregulation (2) is:

(a) communicated to persons at premises adjacent to the workplace who may be affected by an emergency; and

(b) given to emergency services.

Penalty: 10 penalty units.

(4) The employer must review the emergency plan:

(a) within 5 years after the plan is developed, and afterwards at intervals of not more than 5 years; and

(b) if there is a change in circumstances at the workplace.

(5) In developing or reviewing the emergency plan, the employer must:

(a) give a copy of the plan to the emergency services; and

(b) if an emergency service provides written advice to the employer about the plan — have regard to that written advice.

Penalty: 10 penalty units.

8.28 Elimination of ignition sources in hazardous areas

An employer must ensure that:

(a) as far as practicable, there are no ignition sources in a hazardous area at the workplace; or

(b) if it is not practicable to remove an ignition source from a hazardous area, any risk resulting from the ignition source is controlled.

Penalty: 10 penalty units.

8.29 Safety equipment for controlling risks

If equipment is necessary for the control of a risk in relation to the storage or handling of dangerous goods in a workplace, the employer must ensure that the equipment is:

(a) available to relevant persons; and

(b) maintained in accordance with the manufacturer’s specifications.

Penalty: 10 penalty units.

8.30 Control of hazardous atmosphere

An employer must ensure that any risk to a person’s health or safety associated with any atmospheric conditions arising from the storage or handling of dangerous goods is eliminated, or, if this is not practicable, reduced as far as practicable.

Penalty: 10 penalty units.

8.31 Provision of suitable lighting

(1) An employer must ensure that sufficient and appropriate lighting is provided at a workplace at which dangerous goods are stored or handled.

Penalty: 10 penalty units.

(2) The lighting must be such that relevant persons are able:

(a) to safely enter, leave and move in, the workplace; and

(b) to work safely in an area of the workplace where dangerous goods are stored or handled.

8.32 Visitor information and supervision

An employer must ensure that a visitor to the workplace who is likely to be affected by the storage or handling of dangerous goods at the workplace is given appropriate information and is supervised appropriately.

Penalty: 10 penalty units.

8.33 Prevention of unauthorised access

An employer at a workplace at which dangerous goods are stored or handled must ensure that, as far as practicable, unauthorised access to the workplace is prevented.

Penalty: 10 penalty units.

8.34 Disposal etc of plant, equipment and containers

If plant, pipework, equipment or a container at a workplace is no longer intended to be used for the storage or handling of dangerous goods, or is to be disposed of, the employer must ensure that the plant, pipework, equipment or container is:

(a) as far as practicable, free from dangerous goods; or

(b) otherwise made safe.

Penalty: 10 penalty units.

Note The expression free from dangerous goods is defined in subregulation 8.04 (6).

Subdivision 8.3.3 Provision of information

8.35 Provision of information for health and safety procedures

(1) An employer must ensure that information that is necessary for the development and implementation of safety procedures for the storage or handling of dangerous goods at the workplace is:

(a) obtained; and

(b) communicated and made available to relevant persons at the workplace.

Penalty: 10 penalty units.

Note Under subsection 16 (1) of the Act, an employer must take all reasonably practicable steps to protect the health and safety at work of the employer’s employees. Under paragraph 16 (2) (e) of the Act, an employer breaches subsection 16 (1) of the Act if the employer fails to take all reasonably practicable steps to provide to the employees, in appropriate languages, the information, instruction, training and supervision necessary to enable them to perform their work in a manner that is safe and without risk to their health.

(2) If the information is communicated in the form of safety signs that warn a relevant person about a hazard or about the relevant person’s responsibilities, the employer must ensure that the signs are displayed in a prominent position as close as practicable to the hazard.

Penalty: 10 penalty units.

(3) If safety procedures for the storage or handling of dangerous goods are developed and implemented, the employer must ensure that the procedures are maintained.

8.36 Material Safety Data Sheets

(1) Subject to subregulation (3), if dangerous goods are supplied to a workplace for storage or handling, the employer must ensure that an MSDS for the dangerous goods:

(a) is obtained:

(i) before, or at the time of, the first supply of dangerous goods of that kind to the workplace; or

(ii) if it is not possible to obtain the MSDS at, or before, that time — as soon as practicable after the dangerous goods are supplied; and

(b) is accessible to all employees, emergency services employees and visitors to the workplace; and

(c) is not changed (other than, in the case of an MSDS provided by an overseas supplier, by being re-formatted).

Penalty: 10 penalty units.

(2) Subject to subregulation (3), if an employee whose duties involve storing or handling dangerous goods asks for an MSDS for the dangerous goods, the employer must ensure that the MSDS is given to the employee.

Penalty: 10 penalty units.

(3) The employer is not required to comply with subregulations (1) and (2) in relation to dangerous goods if:

(a) the dangerous goods are stored or handled as dangerous goods in transit; or

(b) the employer is a retailer, and the dangerous goods are supplied as packaged dangerous goods in the form of a consumer package that:

(i) is intended for supply for use at another workplace; and

(ii) is not intended to be opened at the workplace, other than for taking a sample or tinting paint.

(4) However, an employer must ensure that information about the health and safety aspects of dangerous goods to which subregulation (3) applies is available and accessible to any employee whose duties involve storing or handling the dangerous goods.

Penalty: 10 penalty units.

8.37 Availability of risk assessment records

If an assessment or review in relation to a risk associated with any hazard identified with the storage or handling of dangerous goods at a workplace has been prepared under regulation 8.16, the employer must ensure that a copy of the record, or the most recent assessment, is readily available:

(a) to any employee who is likely to be exposed to the risk associated with the dangerous goods; and

(b) to each health and safety representative at the workplace.

Penalty: 10 penalty units.

8.38 Information for operators of plant and structures

An employer must ensure that a person who operates, has access to, maintains, repairs, inspects, or tests plant or a structure that is used for the storage or handling of dangerous goods is given information about the plant or structure that is necessary for the person to carry out his or her duties safely.

Penalty: 10 penalty units.

8.39 Register of manifest quantities and site plan

(1) This regulation applies to an employer if:

(a) dangerous goods or combustible liquids of a kind mentioned in column 2 of an item of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of any of the dangerous goods or combustible liquids is more than the manifest quantity mentioned in column 5 of that item.

(2) The employer must ensure that:

(a) a register (the register of manifest quantities) complying with subregulation (3) is prepared in relation to the dangerous goods or combustible liquids; and

(b) the register is located, within the workplace, in a place decided in consultation with emergency services; and

(c) the register is readily accessible to Comcare or to emergency services; and

(d) within 7 days of any significant change in any of the information mentioned in subregulation (3), (5) or (6) — the register is revised to take account of the change.

Penalty: 10 penalty units.

(3) For paragraph (2) (a), the register of manifest quantities must include the following:

(a) the date when the register was prepared;

(b) the employer’s name and the address of the workplace;

(c) contact details for 2 people who may be contacted if there is an emergency;

(d) the location and kind of storage of:

(i) dangerous goods; and

(ii) combustible liquids stored with fire risk dangerous goods, if the combustible liquids are:

(A) in bulk; or

(B) packaged combustible liquids in a total quantity of more than 1 000 kg or 1 000 L in a storage area; and

(iii) C1 combustible liquids stored or handled in isolation from dangerous goods;

(e) the Class and, if appropriate, packing group of the dangerous goods and combustible liquids stored or handled at the workplace;

(f) for bulk containers — the number and capacity of each container stored or handled at the workplace;

(g) for each Class of dangerous goods and combustible liquids stored or handled at the workplace in packages and containers:

(i) the current total quantity of those dangerous goods and combustible liquids; or

(ii) the maximum and average quantities of those dangerous goods and combustible liquids;

(h) for dangerous goods of Class 2.3, dangerous goods of packing group I, and dangerous goods in bulk (other than dangerous goods stored or handled at the workplace in intermediate bulk containers) — the proper shipping name, or the product name and UN number, for the dangerous goods;

(i) a site plan of the workplace complying with subregulations (5) and (6).

(4) For dangerous goods in transit, the information mentioned in paragraphs (3) (e), (f), (g) and (h) may be provided in the form of dangerous goods shipping documents that comply with the ADG Code.

Note Chapter 11 of the ADG Code deals with dangerous goods shipping documents.

(5) For paragraph (3) (i), the site plan of the workplace must indicate the location at the workplace of the following:

(a) essential services, including fire services and isolation points for fuel and power;

(b) the register of manifest quantities prepared under subregulation (2);

(c) the main entrance and other entry points;

(d) each Class of dangerous goods;

(e) combustible liquids stored and handled with fire risk dangerous goods, if the combustible liquids are:

(i) in bulk; or

(ii) packaged combustible liquids in a total quantity of more than 1 000 kg or 1 000 L in a storage area;

(f) C1 combustible liquids stored and handled in isolation from dangerous goods;

(g) dangerous goods in transit (if any);

(h) each storage area, and how each storage area is identified;

(i) manufacturing and process areas;

(j) drains.

(6) For paragraph (3) (i), the site plan of the workplace must include a description of the nature of any adjoining or adjacent sites or workplaces.

8.40 Investigating and recording of dangerous occurrences and near misses

(1) An employer must ensure that a system for investigating and recording dangerous occurrences and near misses is:

(a) established and maintained; and

(b) communicated to persons likely to be affected by such occurrences.

(2) The employer must ensure that, if an occurrence that is a dangerous occurrence or near miss occurs:

(a) the occurrence is investigated; and

(b) the occurrence is reported to each person:

(i) who is responsible for taking corrective action in relation to the occurrence; and

(ii) who was affected by the occurrence; and

(c) a record of the occurrence is made and is kept for the life of the workplace; and

(d) the record is made available, on request, to Comcare.

(3) The employer must ensure that, if a dangerous occurrence or near miss occurs and corrective action is necessary:

(a) action is taken immediately after the occurrence:

(i) to assess and control any risk; and

(ii) to make the workplace safe as far as practicable; and

(b) only persons essential to carrying out the corrective action are present; and

(c) the health and safety of each person who carries out the corrective action is protected as far as practicable.

Note 1 Reporting of dangerous occurrences must be done in accordance with section 68 of the Act and Part 5 of the Occupational Health and Safety (Commonwealth Employment) Regulations 1991.

Note 2 A near miss is not required to be reported under this Part.

Subdivision 8.3.4 Notification of storage and handling of dangerous goods

8.41 Employers other than defence employing authority

(1) This regulation applies to an employer, other than the defence employing authority, if:

(a) dangerous goods of a kind mentioned in column 2 of an item of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of any of the dangerous goods is more than the manifest quantity mentioned in column 5 of that item.

(2) The employer must ensure that:

(a) if, on 1 May 2006, manifest quantities of dangerous goods are stored or handled at the workplace, Comcare is notified, before 1 August 2006, of the following matters:

(i) the name of the employer who owns or operates the workplace where the dangerous goods are stored or handled;

(ii) the name and title of a contact person for the workplace;

(iii) details of each Class of dangerous goods stored or handled at the workplace that exceeds the manifest quantity for that Class of dangerous goods;

(iv) the average and maximum quantities of the dangerous goods stored or handled at the workplace;

(v) the location of the dangerous goods at the workplace; and

(b) if, after 1 May 2006, dangerous goods are to be stored or handled at the workplace, Comcare is notified, before the dangerous goods are stored or handled at the workplace, of the following matters:

(i) the name of the employer who owns or operates the workplace where the dangerous goods are to be stored or handled;

(ii) the name and title of a contact person for the workplace;

(iii) details of each Class of dangerous goods to be stored or handled at the workplace that exceeds the manifest quantity for that Class of dangerous goods;

(iv) the average and maximum quantities of the dangerous goods to be stored or handled at the workplace;

(v) the proposed location of the dangerous goods at the workplace; and

(c) Comcare is further notified:

(i) at the end of each period of 2 years after the first notice is given under paragraph (a) or (b) of the matters mentioned in that paragraph; and

(ii) if there is a significant increase or decrease in the manifest quantity of dangerous goods at the workplace — before, or as soon as practicable after, the change in the manifest quantity of the dangerous goods; and

(iii) if there is a change in the name or title of the contact person for the workplace; and

(iv) if manifest quantities of dangerous goods are no longer stored or handled at the workplace; and

(d) any information relevant to the storage or handling of dangerous goods requested by Comcare is provided to Comcare.

Penalty: 10 penalty units.

8.42 Defence employing authority

(1) This regulation applies to the defence employing authority if:

(a) dangerous goods of a kind mentioned in column 2 of an item of Schedule 7 are stored or handled at a workplace controlled by the Australian Defence Organisation; and

(b) the total quantity of any of the dangerous goods is more than the manifest quantity mentioned in column 5 of that item.

(2) If, on 1 May 2006, manifest quantities of dangerous goods are stored or handled at a workplace controlled by the Australian Defence Organisation, the defence employing authority must ensure that, before 1 August 2006, Comcare is given a notice that includes the following matters:

(a) contact details of the person to be contacted for any inquiries in relation to the dangerous goods;

(b) the number of sites where manifest quantities of dangerous goods are stored or handled;

(c) a summary of the safety arrangements developed by the Australian Defence Organisation to ensure the safe storage and handling of manifest quantities of the dangerous goods at the workplace.

Penalty: 10 penalty units.

(3) The defence employing agency must ensure that Comcare is given a further notice, including the matters mentioned in subregulation (2), at the end of each period of 12 months after the first notice is given under subregulation (2).

Penalty: 10 penalty units.

8.43 Form of notices

A notice under this Subdivision must be:

(a) in writing; and

(b) in a form approved by Comcare.

8.44 Comcare to acknowledge receipt of notice

Comcare must acknowledge receipt of a notice under this Subdivision within 3 months after receiving the notice.

Subdivision 8.3.5 Marking and identification of containers

8.45 Marking and identification of containers — dangerous goods received by employer

(1) An employer commits an offence if:

(a) the employer receives dangerous goods; and

(b) the marking for the container in which the dangerous goods are supplied does not comply with the ADG Code; and

(c) the employer is reckless with respect to whether the marking for the container complies with the ADG Code; and

(d) the employer:

(i) accepts the dangerous goods; and

(ii) does not ensure that the container is marked in accordance with the ADG Code.

Penalty: 10 penalty units.

(2) Strict liability applies to the physical element that the container is marked in accordance with the ADG Code.

Note Chapter 7 of the ADG Code deals with marking of packages.

8.46 Marking and identification of containers at the workplace

(1) An employer must ensure that:

(a) a container at the workplace that is marked for use for particular dangerous goods is used only for those dangerous goods; and

(b) the marking on a container of dangerous goods is maintained while the dangerous goods are at the workplace.

Penalty: 10 penalty units.

(2) Strict liability applies to the physical element that the dangerous goods are marked in accordance with this regulation.

8.47 Containers for short-term storage of dangerous goods not required to be marked

Despite regulations 8.45 and 8.46, an employer is not required to mark a container into which dangerous goods are to be transferred if:

(a) the dangerous goods are to be used immediately after the dangerous goods are transferred into the container; and

(b) the container is to be made free from dangerous goods immediately after the dangerous goods have been used.

Penalty: 10 penalty units.

Note The expression free from dangerous goods is defined in subregulation 8.04 (6).

Subdivision 8.3.6 Placards — bulk dangerous goods and HAZCHEM

8.48 Placarding of bulk dangerous goods received by employer

(1) An employer commits an offence if:

(a) the employer receives bulk dangerous goods; and

(b) the placard for the dangerous goods does not comply with the ADG Code; and

(c) the employer is reckless with respect to whether the placard for the dangerous goods does not comply with the ADG Code; and

(d) the employer:

(i) accepts the dangerous goods; and

(ii) does not ensure that the dangerous goods are placarded in accordance with the ADG Code.

Penalty: 10 penalty units.

(2) Strict liability applies to the physical element that the bulk dangerous goods are placarded in accordance with the ADG Code.

Note Chapter 7 of the ADG Code deals with placarding of dangerous goods.

8.49 Bulk dangerous goods placard — dangerous goods stored in bulk

(1) An employer for a workplace where dangerous goods are stored in bulk must ensure that a bulk dangerous goods placard (being a placard that complies with item 1 of Schedule 8) is displayed in a prominent location on, or as close as practicable to, the bulk storage.

Penalty: 10 penalty units.

(2) An employer for a workplace where C1 combustible liquids are stored in bulk must ensure that a C1 combustible liquids placard (being a placard that complies with item 2 of Schedule 8) is displayed in a prominent location on, or as close as practicable to, the bulk storage.

Penalty: 10 penalty units.

(3) An offence against subregulation (1) or (2) is an offence of strict liability.

(4) This regulation does not apply in relation to:

(a) dangerous goods in bulk in an intermediate bulk container or in a bulk container intended for transport; or

(b) C1 combustible liquids that are:

(i) in a quantity of not more than 10 000 L; and

(ii) isolated from other dangerous goods; or

(c) Class 2.1 or Class 3 dangerous goods or C1 combustible liquids that are stored in an underground tank at a service station.

8.50 HAZCHEM outer warning placards — quantity of dangerous goods or combustible liquids exceeds placarding quantity

(1) This regulation applies to an employer if:

(a) dangerous goods mentioned in column 2 of an item of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of the dangerous goods is more than the placarding quantity mentioned in column 4 of that item.

(2) The employer must ensure that a HAZCHEM outer warning placard (being a placard that complies with item 4 of Schedule 8) is positioned at each entrance to the workplace through which emergency services could, in an emergency, gain entry to the workplace.

Penalty: 10 penalty units.

(3) An offence against subregulation (2) is an offence of strict liability.

Subdivision 8.3.7 Other placards — quantity of packaged dangerous goods or combustible liquids exceeds placarding quantity

8.51 Application

(1) This Subdivision applies to an employer if:

(a) packaged dangerous goods mentioned in an item of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of the packaged dangerous goods is greater than the placarding quantity mentioned in column 4 of the item.

(2) This Subdivision does not apply to liquefied petroleum gas stored in cylinders outside a building if the cylinders are connected by piping to gas-consuming appliances inside the building.

8.52 Placards — general

(1) The employer must ensure that a placard in accordance with this regulation is displayed at the workplace.

Penalty: 10 penalty units.

(2) An offence against subregulation (1) is an offence of strict liability.

(3) If:

(a) packaged dangerous goods of a Class or Subclass mentioned in any of items 1 to 20 of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of the dangerous goods is greater than the placarding quantity mentioned in column 4 of that item;

the placard must display a Class label for that Class of dangerous goods.

(4) If:

(a) there is more than 1 Class of dangerous goods in the packaged dangerous goods; and

(b) 2 or more Classes of dangerous goods in the packaged dangerous goods have the same Subsidiary Risk; and

(c) the total quantity of dangerous goods that have the same Subsidiary Risk is greater than 1 000 kg or L;

the placard must display a Class label for each Class of dangerous goods of that Subsidiary Risk.

(5) If:

(a) packaged dangerous goods of a Class or Subclass mentioned in item 21 or 22 of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of the dangerous goods is greater than the placarding quantity mentioned in column 4 of the item;

the placard must display a Class label for each Class of dangerous goods the quantity of which is greater than half of the placarding quantity mentioned in Schedule 7 for that Class.

(6) The placard must display a Class 3 Class label if:

(a) dangerous goods mentioned in item 24 of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of the dangerous goods is greater than the placarding quantity mentioned in column 4 of that item.

(7) The placard must display a mixed Class label if:

(a) mixed Classes of dangerous goods mentioned in item 21 or 22 of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of the mixed Classes of dangerous goods is greater than the placarding quantity mentioned in the applicable item; and

(c) a Class label for the dangerous goods is not otherwise required under this regulation.

8.53 Placard for goods too dangerous to be transported

(1) The employer must ensure that a placard for goods too dangerous to be transported (being a placard that complies with item 5 of Schedule 8) is displayed at the workplace if:

(a) dangerous goods mentioned in column 2 of item 23 of Schedule 7 are stored or handled at the workplace; and

(b) the total quantity of the dangerous goods is more than the placarding quantity mentioned in column 4 of that item.

Penalty: 10 penalty units.

(2) An offence against subregulation (1) is an offence of strict liability.

8.54 Placard for C1 combustible liquids

(1) The employer must ensure that a C1 combustible liquids placard (being a placard that complies with item 2 of Schedule 8) is displayed at the workplace if:

(a) C1 combustible liquids of a Class mentioned in column 2 of item 25, 26 or 27 of Schedule 7 are stored or handled at the workplace in isolation from dangerous goods; and