Schedule 1—International Convention for the Safety of Life at Sea, 1974

Subsection 187A(1)

ARTICLE I

General Obligations under the Convention

(a) The Contracting Governments undertake to give effect to the provisions of the present Convention and the Annex thereto, which shall constitute an integral part of the present Convention. Every reference to the present Convention constitutes at the same time a reference to the Annex.

(b) The Contracting Governments undertake to promulgate all laws, decrees, orders and regulations and to take all other steps which may be necessary to give the present Convention full and complete effect, so as to ensure that, from the point of view of safety of life, a ship is fit for the service for which it is intended.

ARTICLE II

Application

The present Convention shall apply to ships entitled to fly the flag of States the Governments of which are Contracting Governments.

ARTICLE III

Laws, Regulations

The Contracting Governments undertake to communicate to and deposit with the Secretary‑General of the Inter‑Governmental Maritime Consultative Organization (hereinafter referred to as “the Organization”):

(a) a list of non‑governmental agencies which are authorized to act in their behalf in the administration of measures for safety of life at sea for circulation to the Contracting Governments for the information of their officers;

(b) the text of laws, decrees, orders and regulations which shall have been promulgated on the various matters within the scope of the present Convention;

(c) a sufficient number of specimens of their Certificates issued under the provisions of the present Convention for circulation to the Contracting Governments for the information of their officers.

ARTICLE IV

Cases of Force Majeure

(a) A ship, which is not subject to the provisions of the present Convention at the time of its departure on any voyage, shall not become subject to the provisions of the present Convention on account of any deviation from its intended voyage due to stress of weather or any other cause of force majeure.

(b) Persons who are on board a ship by reason of force majeure or in consequence of the obligation laid upon the master to carry shipwrecked or other persons shall not be taken into account for the purpose of ascertaining the application to a ship of any provisions of the present Convention.

ARTICLE V

Carriage of Persons in Emergency

(a) For the purpose of evacuating persons in order to avoid a threat to the security of their lives a Contracting Government may permit the carriage of a larger number of persons in its ships than is otherwise permissible under the present Convention.

(b) Such permission shall not deprive other Contracting Governments of any right of control under the present Convention over such ships which come within their ports.

(c) Notice of any such permission, together with a statement of the circumstances, shall be sent to the Secretary‑General of the Organization by the Contracting Government granting such permission.

ARTICLE VI

Prior Treaties and Conventions

(a) As between the Contracting Governments, the present Convention replaces and abrogates the International Convention for the Safety of Life at Sea which was signed in London on 17 June 1960.

(b) All other treaties, conventions and arrangements relating to safety of life at sea, or matters appertaining thereto, at present in force between Governments parties to the present Convention shall continue to have full and complete effect during the terms thereof as regards:

(i) ships to which the present Convention does not apply;

(ii) ships to which the present Convention applies, in respect of matters for which it has not expressly provided.

(c) To the extent, however, that such treaties, conventions or arrangements conflict with the provisions of the present Convention, the provisions of the present Convention shall prevail.

(d) All matters which are not expressly provided for in the present Convention remain subject to the legislation of the Contracting Governments.

ARTICLE VII

Special Rules drawn up by Agreement

When in accordance with the present Convention special rules are drawn up by agreement between all or some of the Contracting Governments, such rules shall be communicated to the Secretary‑General of the Organization for circulation to all Contracting Governments.

ARTICLE VIII

Amendments

(a) The present Convention may be amended by either of the procedures specified in the following paragraphs.

(b) Amendments after consideration within the Organization:

(i) Any amendment proposed by a Contracting Government shall be submitted to the Secretary‑General of the Organization, who shall then circulate it to all Members of the Organization and all Contracting Governments at least six months prior to its consideration.

(ii) Any amendment proposed and circulated as above shall be referred to the Maritime Safety Committee of the Organization for consideration.

(iii) Contracting Governments of States, whether or not Members of the Organization, shall be entitled to participate in the proceedings of the Maritime Safety Committee for the consideration and adoption of amendments.

(iv) Amendments shall be adopted by a two‑thirds majority of the Contracting Governments present and voting in the Maritime Safety Committee expanded as provided for in sub‑paragraph (iii) of this paragraph (hereinafter referred to as “the expanded Maritime Safety Committee”) on condition that at least one‑third of the Contracting Governments shall be present at the time of voting.

(v) Amendments adopted in accordance with sub‑paragraph (iv) of this paragraph shall be communicated by the Secretary‑General of the Organization to all Contracting Governments for acceptance.

(vi) (1) An amendment to an Article of the Convention or to Chapter I of the Annex shall be deemed to have been accepted on the date on which it is accepted by two‑thirds of the Contracting Governments.

(2) An amendment to the Annex other than Chapter I shall be deemed to have been accepted:

(aa) at the end of two years from the date on which it is communicated to Contracting Governments for acceptance; or

(bb) at the end of a different period, which shall not be less than one year, if so determined at the time of its adoption by a two‑thirds majority of the Contracting Governments present and voting in the expanded Maritime Safety Committee.

However, if within the specified period either more than one‑third of Contracting Governments, or Contracting Governments the combined merchant fleets of which constitute not less than fifty per cent of the gross tonnage of the world’s merchant fleet, notify the Secretary‑General of the Organization that they object to the amendment, it shall be deemed not to have been accepted.

(vii) (1) An amendment to an Article of the Convention or to Chapter I of the Annex shall enter into force with respect to those Contracting Governments which have accepted it, six months after the date on which it is deemed to have been accepted, and with respect to each Contracting Government which accepts it after that date, six months after the date of that Contracting Government’s acceptance.

(2) An amendment to the Annex other than Chapter I shall enter into force with respect to all Contracting Governments, except those which have objected to the amendment under sub‑paragraph (vi)(2) of this paragraph and which have not withdrawn such objections, six months after the date on which it is deemed to have been accepted. However, before the date set for entry into force, any Contracting Government may give notice to the Secretary‑General of the Organization that it exempts itself from giving effect to that amendment for a period not longer than one year from the date of its entry into force, or for such longer period as may be determined by a two‑thirds majority of the Contracting Governments present and voting in the expanded Maritime Safety Committee at the time of the adoption of the amendment.

(c) Amendment by a Conference:

(i) Upon the request of a Contracting Government concurred in by at least one‑third of the Contracting Governments, the Organization shall convene a Conference of Contracting Governments to consider amendments to the present Convention.

(ii) Every amendment adopted by such a Conference by a two‑thirds majority of the Contracting Governments present and voting shall be communicated by the Secretary‑General of the Organization to all Contracting Governments for acceptance.

(iii) Unless the Conference decides otherwise, the amendment shall be deemed to have been accepted and shall enter into force in accordance with the procedures specified in sub‑paragraphs (b)(vi) and (b)(vii) respectively of this Article, provided that references in these paragraphs to the expanded Maritime Safety Committee shall be taken to mean references to the Conference.

(d) (i) A Contracting Government which has accepted an amendment to the Annex which has entered into force shall not be obliged to extend the benefit of the present Convention in respect of the certificates issued to a ship entitled to fly the flag of a State the Government of which, pursuant to the provisions of sub‑paragraph (b)(vi)(2) of this Article, has objected to the amendment and has not withdrawn such an objection, but only to the extent that such certificates relate to matters covered by the amendment in question.

(ii) A Contracting Government which has accepted an amendment to the Annex which has entered into force shall extend the benefit of the present Convention in respect of the certificates issued to a ship entitled to fly the flag of a State the Government of which, pursuant to the provisions of sub‑paragraph (b)(vii)(2) of this Article, has notified the Secretary‑General of the Organization that it exempts itself from giving effect to the amendment.

(e) Unless expressly provided otherwise, any amendment to the present Convention made under this Article, which relates to the structure of a ship, shall apply only to ships the keels of which are laid or which are at a similar stage of construction, on or after the date on which the amendment enters into force.

(f) Any declaration of acceptance of, or objection to, an amendment or any notice given under sub‑paragraph (b)(vii)(2) of this Article shall be submitted in writing to the Secretary‑General of the Organization, who shall inform all Contracting Governments of any such submission and the date of its receipt.

(g) The Secretary‑General of the Organization shall inform all Contracting Governments of any amendments which enter into force under this Article, together with the date on which each such amendment enters into force.

ARTICLE IX

Signature, Ratification, Acceptance, Approval and Accession

(a) The present Convention shall remain open for signature at the Headquarters of the Organization from 1 November 1974 until 1 July 1975 and shall thereafter remain open for accession. States may become parties to the present Convention by:

(i) signature without reservation as to ratification, acceptance or approval; or

(ii) signature subject to ratification, acceptance or approval, followed by ratification, acceptance or approval; or

(iii) accession.

(b) Ratification, acceptance, approval or accession shall be effected by the deposit of an instrument to that effect with the Secretary‑General of the Organization.

(c) The Secretary‑General of the Organization shall inform the Governments of all States which have signed the present Convention or acceded to it of any signature or of the deposit of any instrument of ratification, acceptance, approval or accession and the date of its deposit.

ARTICLE X

Entry into Force

(a) The present Convention shall enter into force twelve months after the date on which not less than twenty‑five States, the combined merchant fleets of which constitute not less than fifty per cent of the gross tonnage of the world’s merchant shipping, have become parties to it in accordance with Article IX.

(b) Any instrument of ratification, acceptance, approval or accession deposited after the date on which the present Convention enters into force shall take effect three months after the date of deposit.

(c) After the date on which an amendment to the present Convention is deemed to have been accepted under Article VIII, any instrument of ratification, acceptance, approval or accession deposited shall apply to the Convention as amended.

ARTICLE XI

Denunciation

(a) The present Convention may be denounced by any Contracting Government at any time after the expiry of five years from the date on which the Convention enters into force for that Government.

(b) Denunciation shall be effected by the deposit of an instrument of denunciation with the Secretary‑General of the Organization who shall notify all the other Contracting Governments of any instrument of denunciation received and of the date of its receipt as well as the date on which such denunciation takes effect.

(c) A denunciation shall take effect one year, or such longer period as may be specified in the instrument of denunciation, after its receipt by the Secretary‑General of the Organization.

ARTICLE XII

Deposit and Registration

(a) The present Convention shall be deposited with the Secretary‑General of the Organization who shall transmit certified true copies thereof to the Governments of all States which have signed the present Convention or acceded to it.

(b) As soon as the present Convention enters into force, the text shall be transmitted by the Secretary‑General of the Organization to the Secretary‑General of the United Nations for registration and publication, in accordance with Article 102 of the Charter of the United Nations.

ARTICLE XIII

Languages

The present Convention is established in a single copy in the Chinese, English, French, Russian and Spanish languages, each text being equally authentic. Official translations in the Arabic, German and Italian languages shall be prepared and deposited with the signed original.

ANNEX

CHAPTER I

GENERAL PROVISIONS

PART A—APPLICATION, DEFINITIONS, ETC.

Regulation 1

Application

(a) Unless expressly provided otherwise, the present Regulations apply only to ships engaged on international voyages.

(b) The classes of ships to which each Chapter applies are more precisely defined, and the extent of the application is shown, in each Chapter.

Regulation 2

Definitions

For the purpose of the present Regulations, unless expressly provided otherwise:

(a) “Regulations” means the Regulations contained in the Annex to the present Convention.

(b) “Administration” means the Government of the State whose flag the ship is entitled to fly.

(c) “Approved” means approved by the Administration.

(d) “International voyage” means a voyage from a country to which the present Convention applies to a port outside such country, or conversely.

(e) A passenger is every person other than:

(i) the master and the members of the crew or other persons employed or engaged in any capacity on board a ship on the business of that ship; and

(ii) a child under one year of age.

(f) A passenger ship is a ship which carries more than twelve passengers.

(g) A cargo ship is any ship which is not a passenger ship.

(h) A tanker is a cargo ship constructed or adapted for the carriage in bulk of liquid cargoes of an inflammable nature.

(i) A fishing vessel is a vessel used for catching fish, whales, seals, walrus or other living resources of the sea.

(j) A nuclear ship is a ship provided with a nuclear power plant.

(k) “New ship” means a ship the keel of which is laid or which is at a similar stage of construction on or after the date of coming into force of the present Convention.

(l) “Existing ship” means a ship which is not a new ship.

(m) A mile is 1,852 metres or 6,080 feet.

Regulation 3

Exceptions

(a) The present Regulations, unless expressly provided otherwise, do not apply to:

(i) Ships of war and troopships.

(ii) Cargo ships of less than 500 tons gross tonnage.

(iii) Ships not propelled by mechanical means.

(iv) Wooden ships of primitive build.

(v) Pleasure yachts not engaged in trade.

(vi) Fishing vessels.

(b) Except as expressly provided in Chapter V, nothing herein shall apply to ships solely navigating the Great Lakes of North America and the River St. Lawrence as far east as a straight line drawn from Cap des Rosiers to West Point, Anticosti Island and, on the north side of Anticosti Island, the 63rd Meridian.

Regulation 4

Exemptions

(a) A ship which is not normally engaged on international voyages but which, in exceptional circumstances, is required to undertake a single international voyage may be exempted by the Administration from any of the requirements of the present Regulations provided that it complies with safety requirements which are adequate in the opinion of the Administration for the voyage which is to be undertaken by the ship.

(b) The Administration may exempt any ship which embodies features of a novel kind from any of the provisions of Chapters II–1, II–2, III and IV of these Regulations the application of which might seriously impede research into the development of such features and their incorporation in ships engaged on international voyages. Any such ship shall, however, comply with safety requirements which, in the opinion of that Administration, are adequate for the service for which it is intended and are such as to ensure the overall safety of the ship and which are acceptable to the Governments of the States to be visited by the ship. The Administration which allows any such exemption shall communicate to the Organization particulars of same and the reasons therefor which the Organization shall circulate to the Contracting Governments for their information.

Regulation 5

Equivalents

(a) Where the present Regulations require that a particular fitting, material, appliance or apparatus, or type thereof, shall be fitted or carried in a ship, or that any particular provision shall be made, the Administration may allow any other fitting, material, appliance or apparatus, or type thereof, to be fitted or carried, or any other provision to be made in that ship, if it is satisfied by trial thereof or otherwise that such fitting, material, appliance or apparatus, or type thereof, or provision, is at least as effective as that required by the present Regulations.

(b) Any Administration which so allows, in substitution, a fitting, material, appliance or apparatus, or type thereof, or provision, shall communicate to the Organization particulars thereof together with a report on any trials made and the Organization shall circulate such particulars to other Contracting Governments for the information of their officers.

PART B—SURVEYS AND CERTIFICATES

Regulation 6

Inspection and Survey

The inspection and survey of ships, so far as regards the enforcement of the provisions of the present Regulations and the granting of exemptions therefrom, shall be carried out by officers of the country in which the ship is registered, provided that the Government of each country may entrust the inspection and survey either to surveyors nominated for the purpose or to organizations recognized by it. In every case the Government concerned fully guarantees the completeness and efficiency of the inspection and survey.

Regulation 7

Surveys of Passenger Ships

(a) A passenger ship shall be subjected to the surveys specified below:

(i) A survey before the ship is put in service.

(ii) A periodical survey once every twelve months.

(iii) Additional surveys, as occasion arises.

(b) The surveys referred to above shall be carried out as follows:

(i) The survey before the ship is put in service shall include a complete inspection of its structure, machinery and equipment, including the outside of the ship’s bottom and the inside and outside of the boilers. This survey shall be such as to ensure that the arrangements, material, and scantlings of the structure, boilers and other pressure vessels and their appurtenances, main and auxiliary machinery, electrical installation, radio installation, radiotelegraph installations in motor lifeboats, portable radio apparatus for survival craft, life‑saving appliances, fire protection, fire detecting and extinguishing appliances, radar, echo‑sounding device, gyro‑compass, pilot ladders, mechanical pilot hoists and other equipment, fully comply with the requirements of the present Convention, and of the laws, decrees, orders and regulations promulgated as a result thereof by the Administration for ships of the service for which it is intended. The survey shall also be such as to ensure that the workmanship of all parts of the ship and its equipment is in all respects satisfactory, and that the ship is provided with the lights, shapes, means of making sound signals and distress signals as required by the provisions of the present Convention and the International Regulations for Preventing Collisions at Sea in force.

(ii) The periodical survey shall include an inspection of the structure, boilers and other pressure vessels, machinery and equipment, including the outside of the ship’s bottom. The survey shall be such as to ensure that the ship, as regards the structure, boilers and other pressure vessels and their appurtenances, main and auxiliary machinery, electrical installation, radio installation, radiotelegraph installations in motor lifeboats, portable radio apparatus for survival craft, life‑saving appliances, fire protection, fire detecting and extinguishing appliances, radar, echo‑sounding device, gyro‑compass, pilot ladders, mechanical pilot hoists and other equipment, is in satisfactory condition and fit for the service for which it is intended, and that it complies with the requirements of the present Convention, and of the laws, decrees, orders and regulations promulgated as a result thereof by the Administration. The lights, shapes and means of making sound signals and the distress signals carried by the ship shall also be subject to the above‑mentioned survey for the purpose of ensuring that they comply with the requirements of the present Convention and of the International Regulations for Preventing Collisions at Sea in force.

(iii) A survey either general or partial, according to the circumstances, shall be made every time an accident occurs or a defect is discovered which affects the safety of the ship or the efficiency or completeness of its life‑saving appliances or other equipment, or whenever any important repairs or renewals are made. The survey shall be such as to ensure that the necessary repairs or renewals have been effectively made, that the material and workmanship of such repairs are in all respects satisfactory, and that the ship complies in all respects with the provisions of the present Convention and of the International Regulations for Preventing Collisions at Sea in force, and of the laws, decrees, orders and regulations promulgated as a result thereof by the Administration.

(c) (i) The laws, decrees, orders and regulations referred to in paragraph (b) of this Regulation shall be in all respects such as to ensure that, from the point of view of safety of life, the ship is fit for the service for which it is intended.

(ii) They shall among other things prescribe the requirements to be observed as to the initial and subsequent hydraulic or other acceptable alternative tests to which the main and auxiliary boilers, connexions, steam pipes, high pressure receivers, and fuel tanks for internal combustion engines are to be submitted including the test procedures to be followed and the intervals between two consecutive tests.

Regulation 8

Surveys of Life‑Saving Appliances and other Equipment of Cargo Ships

The life‑saving appliances, except a radiotelegraph installation in a motor lifeboat or a portable radio apparatus for survival craft, the echo‑sounding device, the gyro‑compass, and the fire‑extinguishing appliances of cargo ships to which Chapters II–1, II–2, III and V apply shall be subject to initial and subsequent surveys as provided for passenger ships in Regulation 7 of this Chapter with the substitution of 24 months for 12 months in sub‑paragraph (a)(ii) of that Regulation. The fire control plans in new ships and the pilot ladders, mechanical pilot hoists, lights, shapes and means of making sound signals carried by new and existing ships shall be included in the surveys for the purpose of ensuring that they comply fully with the requirements of the present Convention and, where applicable, the International Regulations for Preventing Collisions at Sea in force.

Regulation 9

Surveys of Radio and Radar Installations of Cargo Ships

The radio and radar installations of cargo ships to which Chapters IV and V apply and any radiotelegraph installation in a motor lifeboat or portable radio apparatus for survival craft which is carried in compliance with the requirements of Chapter III shall be subject to initial and subsequent surveys as provided for passenger ships in Regulation 7 of this Chapter.

Regulation 10

Surveys of Hull, Machinery and Equipment of Cargo Ships

The hull, machinery and equipment (other than items in respect of which Cargo Ship Safety Equipment Certificates, Cargo Ship Safety Radiotelegraphy Certificates or Cargo Ship Safety Radiotelephony Certificates are issued) of a cargo ship shall be surveyed on completion and thereafter in such manner and at such intervals as the Administration may consider necessary in order to ensure that their condition is in all respects satisfactory. The survey shall be such as to ensure that the arrangements, material, and scantlings of the structure, boilers and other pressure vessels and their appurtenances, main and auxiliary machinery, electrical installations and other equipment are in all respects satisfactory for the service for which the ship is intended.

Regulation 11

Maintenance of Conditions after Survey

After any survey of the ship under Regulations 7, 8, 9 or 10 of this Chapter has been completed, no change shall be made in the structural arrangements, machinery, equipment, etc. covered by the survey, without the sanction of the Administration.

Regulation 12

Issue of Certificates

(a) (i) A certificate called a Passenger Ship Safety Certificate shall be issued after inspection and survey to a passenger ship which complies with the requirements of Chapters II–1, II–2, III and IV and any other relevant requirements of the present Regulations.

(ii) A certificate called a Cargo Ship Safety Construction Certificate shall be issued after survey to a cargo ship which satisfies the requirements for cargo ships on survey set out in Regulation 10 of this Chapter and complies with the applicable requirements of Chapters II–1 and II–2 other than those relating to fire‑extinguishing appliances and fire control plans.

(iii) A certificate called a Cargo Ship Safety Equipment Certificate shall be issued after inspection to a cargo ship which complies with the relevant requirements of Chapters II–1, II–2 and III and any other relevant requirements of the present Regulations.

(iv) A certificate called a Cargo Ship Safety Radiotelegraphy Certificate shall be issued after inspection to a cargo ship, fitted with a radiotelegraph installation, which complies with the requirements of Chapter IV and any other relevant requirements of the present Regulations.

(v) A certificate called a Cargo Ship Safety Radiotelephony Certificate shall be issued after inspection to a cargo ship, fitted with a radiotelephone installation, which complies with the requirements of Chapter IV and any other relevant requirements of the present Regulations.

(vi) When an exemption is granted to a ship under and in accordance with the provisions of the present Regulations, a certificate called an Exemption Certificate shall be issued in addition to the certificates prescribed in this paragraph.

(vii) Passenger Ship Safety Certificates, Cargo Ship Safety Construction Certificates, Cargo Ship Safety Equipment Certificates, Cargo Ship Safety Radiotelegraphy Certificates, Cargo Ship Safety Radiotelephony Certificates and Exemption Certificates shall be issued either by the Administration or by any person or organization duly authorized by it. In every case, that Administration assumes full responsibility for the Certificate.

(b) Notwithstanding any other provision of the present Convention any certificate issued under, and in accordance with, the provisions of the International Convention for the Safety of Life at Sea, 1960, which is current when the present Convention comes into force in respect of the Administration by which the certificate is issued, shall remain valid until it expires under the terms of Regulation 14 of Chapter I of that Convention.

(c) A Contracting Government shall not issue certificates under, and in accordance with, the provisions of the International Convention for the Safety of Life at Sea, 1960, 1948 or 1929, after the date on which acceptance of the present Convention by the Government takes effect.

Regulation 13

Issue of Certificate by another Government

A Contracting Government may, at the request of the Administration, cause a ship to be surveyed and, if satisfied that the requirements of the present Regulations are complied with, shall issue certificates to the ship in accordance with the present Regulations. Any certificate so issued must contain a statement to the effect that it has been issued at the request of the Government of the country in which the ship is or will be registered, and it shall have the same force and receive the same recognition as a certificate issued under Regulation 12 of this Chapter.

Regulation 14

Duration of Certificates

(a) Certificates other than Cargo Ship Safety Construction Certificates, Cargo Ship Safety Equipment Certificates and Exemption Certificates shall be issued for a period of not more than 12 months. Cargo Ship Safety Equipment Certificates shall be issued for a period of not more than 24 months. Exemption Certificates shall not be valid for longer than the period of the certificates to which they refer.

(b) If a survey takes place within two months before the end of the period for which a Cargo Ship Safety Radiotelegraphy Certificate or a Cargo Ship Safety Radiotelephony Certificate issued in respect of cargo ships of 300 tons gross tonnage and upwards, but less than 500 tons gross tonnage, was originally issued, that certificate may be withdrawn, and a new certificate may be issued which shall expire 12 months after the end of the said period.

(c) If a ship at the time when its certificate expires is not in a port of the country in which it is registered, the certificate may be extended by the Administration, but such extension shall be granted only for the purpose of allowing the ship to complete its voyage to the country in which it is registered or is to be surveyed, and then only in cases where it appears proper and reasonable so to do.

(d) No certificate shall be thus extended for a longer period than five months, and a ship to which such extension is granted shall not, on its arrival in the country in which it is registered or the port in which it is to be surveyed, be entitled by virtue of such extension to leave that port or country without having obtained a new certificate.

(e) A certificate which has not been extended under the foregoing provisions of this Regulation may be extended by the Administration for a period of grace of up to one month from the date of expiry stated on it.

Regulation 15

Form of Certificates

(a) All certificates shall be drawn up in the official language or languages of the country by which they are issued.

(b) The form of the certificates shall be that of the models given in the Appendix to the present Regulations. The arrangement of the printed part of the model certificates shall be exactly reproduced in the certificates issued, or in certified copies thereof, and the particulars inserted in the certificates issued, or in certified copies thereof, shall be in Roman characters and Arabic figures.

Regulation 16

Posting up of Certificates

All certificates or certified copies thereof issued under the present Regulations shall be posted up in a prominent and accessible place in the ship.

Regulation 17

Acceptance of Certificates

Certificates issued under the authority of a Contracting Government shall be accepted by the other Contracting Governments for all purposes covered by the present Convention. They shall be regarded by the other Contracting Governments as having the same force as certificates issued by them.

Regulation 18

Qualification of Certificates

(a) If in the course of a particular voyage a ship has on board a number of persons less than the total number stated in the Passenger Ship Safety Certificate and is in consequence, in accordance with the provisions of the present Regulations, free to carry a smaller number of lifeboats and other life‑saving appliances than that stated in the Certificate, an annex may be issued by the Government, person or organization referred to in Regulation 12 or 13 of this Chapter.

(b) This annex shall state that in the circumstances there is no infringement of the provisions of the present Regulations. It shall be annexed to the Certificate and shall be substituted for it in so far as the life‑saving appliances are concerned. It shall be valid only for the particular voyage for which it is issued.

Regulation 19

Control

Every ship holding a certificate issued under Regulation 12 or Regulation 13 of this Chapter is subject in the ports of the other Contracting Governments to control by officers duly authorized by such Governments in so far as this control is directed towards verifying that there is on board a valid certificate. Such certificate shall be accepted unless there are clear grounds for believing that the condition of the ship or of its equipment does not correspond substantially with the particulars of that certificate. In that case, the officer carrying out the control shall take such steps as will ensure that the ship shall not sail until it can proceed to sea without danger to the passengers or the crew. In the event of this control giving rise to intervention of any kind, the officer carrying out the control shall inform the Consul of the country in which the ship is registered in writing forthwith of all the circumstances in which intervention was deemed to be necessary, and the facts shall be reported to the Organization.

Regulation 20

Privileges

The privileges of the present Convention may not be claimed in favour of any ship unless it holds appropriate valid certificates.

PART C—CASUALTIES

Regulation 21

Casualties

(a) Each Administration undertakes to conduct an investigation of any casualty occurring to any of its ships subject to the provisions of the present Convention when it judges that such an investigation may assist in determining what changes in the present Regulations might be desirable.

(b) Each Contracting Government undertakes to supply the Organization with pertinent information concerning the findings of such investigations. No reports or recommendations of the Organization based upon such information shall disclose the identity or nationality of the ships concerned or in any manner fix or imply responsibility upon any ship or person.

CHAPTER II–1

CONSTRUCTION—SUBDIVISION AND STABILITY, MACHINERY AND ELECTRICAL INSTALLATIONS

PART A—GENERAL

Regulation 1

Application

(a) (i) Unless expressly provided otherwise, this Chapter applies to new ships.

(ii) Existing passenger ships and cargo ships shall comply with the following:

(1) for ships the keels of which were laid or which were at a similar stage of construction on or after the date of coming into force of the International Convention for the Safety of Life at Sea, 1960, the Administration shall ensure that the requirements which were applied under Chapter II of that Convention to new ships as defined in that Chapter are complied with;

(2) for ships the keels of which were laid or which were at a similar stage of construction on or after the date of coming into force of the International Convention for the Safety of Life at Sea, 1948, but before the date of coming into force of the International Convention for the Safety of Life at Sea, 1960, the Administration shall ensure that the requirements which were applied under Chapter II of the 1948 Convention to new ships as defined in that Chapter are complied with;

(3) for ships the keels of which were laid or which were at a similar stage of construction before the date of coming into force of the International Convention for the Safety of Life at Sea, 1948, the Administration shall ensure that the requirements which were applied under Chapter II of that Convention to existing ships as defined in that Chapter are complied with;

(4) as regards the requirements of Chapter II–1 of the present Convention which are not contained in Chapter II of the 1960 and 1948 Conventions, the Administration shall decide which of these requirements shall be applied to existing ships as defined in the present Convention.

(iii) A ship which undergoes repairs, alterations, modifications and outfitting related thereto shall continue to comply with at least the requirements previously applicable to the ship. An existing ship in such a case shall not, as a rule, comply to a lesser extent with the requirements for a new ship than it did before. Repairs, alterations and modifications of a major character and outfitting related thereto should meet the requirements for a new ship in so far as the Administration deems reasonable and practicable.

(b) For the purpose of this Chapter:

(i) a new passenger ship is a passenger ship the keel of which is laid or which is at a similar stage of construction on or after the date of coming into force of the present Convention, or a cargo ship which is converted to a passenger ship on or after that date, all other passenger ships being described as existing passenger ships.

(ii) A new cargo ship is a cargo ship the keel of which is laid or which is at a similar stage of construction after the date of coming into force of the present Convention.

(c) The Administration may, if it considers that the sheltered nature and conditions of the voyage are such as to render the application of any specific requirements of this Chapter unreasonable or unnecessary, exempt from those requirements individual ships or classes of ships belonging to its country which, in the course of their voyage, do not proceed more than 20 miles from the nearest land.

(d) In the case of a passenger ship which is permitted under paragraph (c) of Regulation 27 of Chapter III to carry a number of persons on board in excess of the lifeboat capacity provided, it shall comply with the special standards of subdivision set out in paragraph (e) of Regulation 5 of this Chapter, and the associated special provisions regarding permeability in paragraph (d) of Regulation 4 of this Chapter, unless the Administration is satisfied that, having regard to the nature and conditions of the voyage, compliance with the other provisions of the Regulations of this Chapter and Chapter II–2 of the present Convention is sufficient.

(e) In the case of passenger ships which are employed in special trades for the carriage of large numbers of special trade passengers, such as the pilgrim trade, the Administration, if satisfied that it is impracticable to enforce compliance with the requirements of this Chapter, may exempt such ships, when they belong to its country, from those requirements, provided that they comply fully with the provisions of:

(i) the Rules annexed to the Special Trade Passenger Ships Agreement, 1971, and

(ii) the Rules annexed to the Protocol on Space Requirements for Special Trade Passenger Ships, 1973, when it enters into force.

Regulation 2

Definitions

For the purpose of this Chapter, unless expressly provided otherwise:

(a) (i) A subdivision load line is a water‑line used in determining the subdivision of the ship.

(ii) The deepest subdivision load line is the water‑line which corresponds to the greatest draught permitted by the subdivision requirements which are applicable.

(b) The length of the ship is the length measured between perpendiculars taken at the extremities of the deepest subdivision load line.

(c) The breadth of the ship is the extreme width from outside of frame to outside of frame at or below the deepest subdivision load line.

(d) The draught is the vertical distance from the moulded base line amidships to the subdivision load line in question.

(e) The bulkhead deck is the uppermost deck up to which the transverse watertight bulkheads are carried.

(f) The margin line is a line drawn at least 76 millimetres (3 inches) below the upper surface of the bulkhead deck at side.

(g) The permeability of a space is the percentage of that space which can be occupied by water.

The volume of a space which extends above the margin line shall be measured only to the height of that line.

(h) The machinery space is to be taken as extending from the moulded base line to the margin line and between the extreme main transverse watertight bulkheads bounding the spaces containing the main and auxiliary propelling machinery, boilers serving the needs of propulsion, and all permanent coal bunkers.

In the case of unusual arrangements, the Administration may define the limits of the machinery spaces.

(i) Passenger spaces are those which are provided for the accommodation and use of passengers, excluding baggage, store, provision and mail rooms.

For the purposes of Regulations 4 and 5 of this Chapter, spaces provided below the margin line for the accommodation and use of the crew shall be regarded as passenger spaces.

(j) In all case volumes and areas shall be calculated to moulded lines.

PART B—SUBDIVISION AND STABILITY

(Part B applies to passenger ships only, except

that Regulation 19 also applies to cargo ships.)

Regulation 3

Floodable Length

(a) The floodable length at any point of the length of a ship shall be determined by a method of calculation which takes into consideration the form, draught and other characteristics of the ship in question.

(b) In a ship with a continuous bulkhead deck, the floodable length at a given point is the maximum portion of the length of the ship, having its centre at the point in question, which can be flooded under the definite assumptions set forth in Regulation 4 of this Chapter without the ship being submerged beyond the margin line.

(c) (i) In the case of a ship not having a continuous bulkhead deck, the floodable length at any point may be determined to an assumed continuous margin line which at no point is less than 76 millimetres (3 inches) below the top of the deck (at side) to which the bulkheads concerned and the shell are carried watertight.

(ii) Where a portion of an assumed margin line is appreciably below the deck to which bulkheads are carried, the Administration may permit a limited relaxation in the watertightness of those portions of the bulkheads which are above the margin line and immediately under the higher deck.

Regulation 4

Permeability

(a) The definite assumptions referred to in Regulation 3 of this Chapter relate to the permeabilities of the spaces below the margin line.

In determining the floodable length, a uniform average permeability shall be used throughout the whole length of each of the following portions of the ship below the margin line:

(i) the machinery space as defined in Regulation 2 of this Chapter;

(ii) the portion forward of the machinery space; and

(iii) the portion abaft the machinery space.

(b) (i) The uniform average permeability throughout the machinery space shall be determined from the formula—

where:

a = volume of the passenger spaces, as defined in Regulation 2 of this Chapter, which are situated below the margin line within the limits of the machinery space;

c = volume of between deck spaces below the margin line within the limits of the machinery space which are appropriated to cargo, coal or stores;

v = whole volume of the machinery space below the margin line.

(ii) Where it is shown to the satisfaction of the Administration that the average permeability as determined by detailed calculation is less than that given by the formula, the detailed calculated value may be used. For the purpose of such calculation, the permeabilities of passenger spaces, as defined in Regulation 2 of this Chapter, shall be taken as 95, that of all cargo, coal and store spaces as 60, and that of double bottom, oil fuel and other tanks at such values as may be approved in each case.

(c) Except as provided in paragraph (d) of this Regulation, the uniform average permeability throughout the portion of the ship before (or abaft) the machinery space shall be determined from the formula—

where:

a = volume of the passenger spaces, as defined in Regulation 2 of this Chapter, which are situated below the margin line, before (or abaft) the machinery space, and

v = whole volume of the portion of the ship below the margin line before (or abaft) the machinery space.

(d) In the case of a ship which is permitted under paragraph (c) of Regulation 27 of Chapter III to carry a number of persons on board in excess of the lifeboat capacity provided, and is required under paragraph (d) of Regulation 1 of this Chapter to comply with special provisions, the uniform average permeability throughout the portion of the ship before (or abaft) the machinery space shall be determined from the formula—

where:

b = the volume of the spaces below the margin line and above the tops of floors, inner bottom, or peak tanks, as the case may be, which are appropriated to and used as cargo spaces, coal or oil fuel bunkers, store‑rooms, baggage and mail rooms, chain lockers and fresh water tanks, before (or abaft) the machinery space; and

v = whole volume of the portion of the ship below the margin line before (or abaft) the machinery space.

In the case of ships engaged on services where the cargo holds are not generally occupied by any substantial quantities of cargo, no part of the cargo spaces is to be included in calculating “b”.

(e) In the case of unusual arrangements the Administration may allow, or require, a detailed calculation of average permeability for the portions before or abaft the machinery space. For the purpose of such calculation, the permeability of passenger spaces as defined in Regulation 2 of this Chapter shall be taken as 95, that of spaces containing machinery as 85, that of all cargo, coal and store spaces as 60, and that of double bottom, oil fuel and other tanks at such value as may be approved in each case.

(f) Where a between deck compartment between two watertight transverse bulkheads contains any passenger or crew space, the whole of that compartment, less any space completely enclosed within permanent steel bulkheads and appropriated to other purposes, shall be regarded as passenger space. Where, however, the passenger or crew space in question is completely enclosed within permanent steel bulkheads, only the space so enclosed need be considered as passenger space.

Regulation 5

Permissible Length of Compartments

(a) Ships shall be as efficiently subdivided as is possible having regard to the nature of the service for which they are intended. The degree of subdivision shall vary with the length of the ship and with the service, in such manner that the highest degree of subdivision corresponds with the ships of greatest length, primarily engaged in the carriage of passengers.

(b) Factor of Subdivision. The maximum permissible length of a compartment having its centre at any point in the ship’s length is obtained from the floodable length by multiplying the latter by an appropriate factor called the factor of subdivision.

The factor of subdivision shall depend on the length of the ship, and for a given length shall vary according to the nature of the service for which the ship is intended. It shall decrease in a regular and continuous manner:

(i) as the length of the ship increases, and

(ii) from a factor A, applicable to ships primarily engaged in the carriage of cargo, to a factor B, applicable to ships primarily engaged in the carriage of passengers.

The variations of the factors A and B shall be expressed by the following formulae (I) and (II) where L is the length of the ship as defined in Regulation 2 of this Chapter:

L in metres

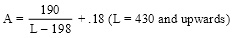

. . . . . . . . . . . . . . . (I)

. . . . . . . . . . . . . . . (I)

L in feet

L in metres

. . . . . . . . . . . . . . . .(II)

. . . . . . . . . . . . . . . .(II)

L in feet

(c) Criterion of Service. For a ship of given length the appropriate factor of subdivision shall be determined by the Criterion of Service Numeral (hereinafter called the Criterion Numeral) as given by the following formulae (III) and (IV) where:

Cs = the Criterion Numeral;

L = Length of the ship, as defined in Regulation 2 of this Chapter;

M = the volume of the machinery space, as defined in Regulation 2 of this Chapter; with the addition thereto of the volume of any permanent oil fuel bunkers which may be situated above the inner bottom and before or abaft the machinery space;

P = the whole volume of the passenger spaces below the margin line, as defined in Regulation 2 of this Chapter;

V = the whole volume of the ship below the margin line;

P1 = KN where:

N = number of passengers for which the ship is to be certified, and

K has the following values:

Value of K

Length in metres and volumes in cubic metres .056L

Length in feet and volumes in cubic feet .6L

Where the value of KN is greater than the sum of P and the whole volume of the actual passenger spaces above the margin line, the figure to be taken as P1 is that sum or two‑thirds KN, whichever is the greater.

When P1 is greater than P—

.......................................(III)

.......................................(III)

and in other cases—

.......................................(IV)

.......................................(IV)

For ships not having a continuous bulkhead deck the volumes are to be taken up to the actual margin lines used in determining the floodable lengths.

(d) Rules for Subdivision of Ships other than those covered by paragraph (e) of this Regulation

(i) The subdivision abaft the forepeak of ships 131 metres (430 feet) in length and upwards having a criterion numeral of 23 or less shall be governed by the factor A given by formula (I); of those having a criterion numeral of 123 or more by the factor B given by formula (II); and of those having a criterion numeral between 23 and 123 by the factor F obtained by linear interpolation between the factors A and B, using the formula:

........................................(V)

........................................(V)

Nevertheless, where the criterion numeral is equal to 45 or more and simultaneously the computed factor of subdivision as given by formula (V) is .65 or less, but more than .50, the subdivision abaft the forepeak shall be governed by the factor .50.

Where the factor F is less than .40 and it is shown to the satisfaction of the Administration to be impracticable to comply with the factor F in a machinery compartment of the ship, the subdivision of such compartment may be governed by an increased factor, which, however, shall not exceed .40.

(ii) The subdivision abaft the forepeak of ships less than 131 metres (430 feet) but not less than 79 metres (260 feet) in length having a criterion numeral equal to S, where—

shall be governed by the factor unity; of those having a criterion numeral of 123 or more by the factor B given by the formula (II); of those having a criterion numeral between S and 123 by the factor F obtained by linear interpolation between unity and the factor B using the formula:

........................................(VI)

........................................(VI)

(iii) The subdivision abaft the forepeak of ships less than 131 metres (430 feet) but not less than 79 metres (260 feet) in length and having a criterion numeral less than S, and of all ships less than 79 metres (260 feet) in length shall be governed by the factor unity, unless, in either case, it is shown to the satisfaction of the Administration to be impracticable to comply with this factor in any part of the ship, in which case the Administration may allow such relaxation as may appear to be justified, having regard to all the circumstances.

(iv) The provisions of sub‑paragraph (iii) of this paragraph shall apply also to ships of whatever length, which are to be certified to carry a number of passengers exceeding 12 but not exceeding—

(e) Special Standards of Subdivision for Ships which are permitted under paragraph (c) of Regulation 27 of Chapter III to carry a number of persons on board in excess of the lifeboat capacity provided and are required under paragraph (d) of Regulation 1 of this Chapter to comply with special provisions

(i) (1) In the case of ships primarily engaged in the carriage of passengers, the subdivision abaft the forepeak shall be governed by a factor of .50 or by the factor determined according to paragraphs (c) and (d) of this Regulation, if less than .50.

(2) In the case of such ships less than 91.5 metres (300 feet) in length, if the Administration is satisfied that compliance with such factor would be impracticable in a compartment, it may allow the length of that compartment to be governed by a higher factor provided the factor used is the lowest that is practicable and reasonable in the circumstances.

(ii) Where, in the case of any ship whether less than 91.5 metres (300 feet) or not, the necessity of carrying appreciable quantities of cargo makes it impracticable to require the subdivision abaft the forepeak to be governed by a factor not exceeding .50, the standard of subdivision to be applied shall be determined in accordance with the following sub‑paragraphs (1) to (5), subject to the condition that where the Administration is satisfied that insistence on strict compliance in any respect would be unreasonable, it may allow such alternative arrangement of the watertight bulkheads as appears to be justified on merits and will not diminish the general effectiveness of the subdivision.

(1) The provisions of paragraph (c) of this Regulation relating to the criterion numeral shall apply with the exception that in calculating the value of P1 for berthed passengers K is to have the value defined in paragraph (c) of this Regulation, or 3.55 cubic metres (125 cubic feet), whichever is the greater, and for unberthed passengers K is to have the value 3.55 cubic metres (125 cubic feet).

(2) The factor B in paragraph (b) of this Regulation shall be replaced by the factor BB determined by the following formula:

L in metres

L in feet

(3) The subdivision abaft the forepeak of ships 131 metres (430 feet) in length and upwards having a criterion numeral of 23 or less shall be governed by the factor A given by formula (I) in paragraph (b) of this Regulation; of those having a criterion numeral of 123 of more by the factor BB given by the formula in sub‑paragraph (ii)(2) of this paragraph; and of those having a criterion numeral between 23 and 123 by the factor F obtained by linear interpolation between the factors A and BB, using the formula:

except that if the factor F so obtained is less than .50 the factor to be used shall be either .50 or the factor calculated according to the provisions of sub‑paragraph (d) (i) of this Regulation, whichever is the smaller.

(4) The subdivision abaft the forepeak of ships less than 131 metres (430 feet) but not less than 55 metres (180 feet) in length having a criterion numeral equal to S1 where—

shall be governed by the factor unity; of those having a criterion numeral of 123 or more by the factor BB given by the formula in sub‑paragraph (ii)(2) of this paragraph; of those having a criterion numeral between S1 and 123 by the factor F obtained by linear interpolation between unity and the factor BB using the formula:

except that in either of the two latter cases if the factor so obtained is less than .50 the subdivision may be governed by a factor not exceeding .50.

(5) The subdivision abaft the forepeak of ships less than 131 metres (430 feet) but not less than 55 metres (180 feet) in length and having a criterion numeral less than S1 and of all ships less than 55 metres (180 feet) in length shall be governed by the factor unity, unless it is shown to the satisfaction of the Administration to be impracticable to comply with this factor in particular compartments, in which event the Administration may allow such relaxations in respect of those compartments as appear to be justified, having regard to all the circumstances, provided that the aftermost compartment and as many as possible of the forward compartments (between the forepeak and the after end of the machinery space) shall be kept within the floodable length.

Regulation 6

Special Rules concerning Subdivision

(a) Where in a portion or portions of a ship the watertight bulkheads are carried to a higher deck than in the remainder of the ship and it is desired to take advantage of this higher extension of the bulkheads in calculating the floodable length, separate margin lines may be used for each such portion of the ship provided that:

(i) the sides of the ship are extended throughout the ship’s length to the deck corresponding to the upper margin line and all openings in the shell plating below this deck throughout the length of the ship are treated as being below a margin line, for the purposes of Regulation 14 of this Chapter; and

(ii) the two compartments adjacent to the “step” in the bulkhead deck are each within the permissible length corresponding to their respective margin lines, and, in addition, their combined length does not exceed twice the permissible length based on the lower margin line.

(b) (i) A compartment may exceed the permissible length determined by the rules of Regulation 5 of this Chapter provided the combined length of each pair of adjacent compartments to which the compartment in question is common does not exceed either the floodable length or twice the permissible length, whichever is the less.

(ii) If one of the two adjacent compartments is situated inside the machinery space, and the second is situated outside the machinery space, and the average permeability of the portion of the ship in which the second is situated differs from that of the machinery space, the combined length of the two compartments shall be adjusted to the mean average permeability of the two portions of the ship in which the compartments are situated.

(iii) Where the two adjacent compartments have different factors of subdivision, the combined length of the two compartments shall be determined proportionately.

(c) In ships 100 metres (330 feet) in length and upwards, one of the main transverse bulkheads abaft the forepeak shall be fitted at a distance from forward perpendicular which is not greater than the permissible length.

(d) A main transverse bulkhead may be recessed provided that all parts of the recess lie inboard of vertical surfaces on both sides of the ship, situated at a distance from the shell plating equal to one‑fifth the breadth of the ship, as defined in Regulation 2 of this Chapter, and measured at right angles to the centre line at the level of the deepest subdivision load line.

Any part of a recess which lies outside these limits shall be dealt with as a step in accordance with paragraph (e) of this Regulation.

(e) A main transverse bulkhead may be stepped provided that it meets one of the following conditions:

(i) the combined length of the two compartments, separated by the bulkhead in question, does not exceed either 90 per cent of the floodable length or twice the permissible length, except that in ships having a factor of subdivision greater than .9, the combined length of the two compartments in question shall not exceed the permissible length;

(ii) additional subdivision is provided in way of the step to maintain the same measure of safety as that secured by a plane bulkhead;

(iii) the compartment over which the step extends does not exceed the permissible length corresponding to a margin line taken 76 millimetres (3 inches) below the step.

(f) Where a main transverse bulkhead is recessed or stepped, an equivalent plane bulkhead shall be used in determining the subdivision.

(g) If the distance between two adjacent main transverse bulkheads, or their equivalent plane bulkheads, or the distance between the transverse planes passing through the nearest stepped portions of the bulkheads, is less than 3.05 metres (10 feet) plus 3 per cent of the length of the ship, or 10.67 metres (35 feet) whichever is the less, only one of these bulkheads shall be regarded as forming part of the subdivision of the ship in accordance with the provisions of Regulation 5 of this Chapter.

(h) Where a main transverse watertight compartment contains local subdivision and it can be shown to the satisfaction of the Administration that, after any assumed side damage extending over a length of 3.05 metres (10 feet) plus 3 per cent of the length of the ship, or 10.67 metres (35 feet) whichever is the less, the whole volume of the main compartment will not be flooded, a proportionate allowance may be made in the permissible length otherwise required for such compartment. In such a case the volume of effective buoyancy assumed on the undamaged side shall not be greater than that assumed on the damaged side.

(i) Where the required factor of subdivision is .50 or less, the combined length of any two adjacent compartments shall not exceed the floodable length.

Regulation 7

Stability of Ships in Damaged Condition

(a) Sufficient intact stability shall be provided in all service conditions so as to enable the ship to withstand the final stage of flooding of any one main compartment which is required to be within the floodable length.

Where two adjacent main compartments are separated by a bulkhead which is stepped under the conditions of sub‑paragraph (e) (i) of Regulation 6 of this Chapter the intact stability shall be adequate to withstand the flooding of those two adjacent main compartments.

Where the required factor of subdivision is .50 or less but more than .33 intact stability shall be adequate to withstand the flooding of any two adjacent main compartments.

Where the required factor of subdivision is .33 or less the intact stability shall be adequate to withstand the flooding of any three adjacent main compartments.

(b) (i) The requirements of paragraph (a) of this Regulation shall be determined by calculations which are in accordance with paragraphs (c), (d) and (f) of this Regulation and which take into consideration the proportions and design characteristics of the ship and the arrangement and configuration of the damaged compartments. In making these calculations the ship is to be assumed in the worst anticipated service condition as regards stability.

(ii) Where it is proposed to fit decks, inner skins or longitudinal bulkheads of sufficient tightness to seriously restrict the flow of water, the Administration shall be satisfied that proper consideration is given to such restrictions in the calculations.

(iii) In cases where the Administration considers the range of stability in the damaged condition to be doubtful, it may require investigation thereof.

(c) For the purpose of making damage stability calculations the volume and surface permeabilities shall be in general as follows:

Spaces | Permeability |

Appropriated to Cargo, Coal or Stores.............. | 60 |

Occupied by Accommodation ................... | 95 |

Occupied by Machinery ....................... | 85 |

Intended for Liquids ......................... | 0 or 95 |

| | |

Higher surface permeabilities are to be assumed in respect of spaces which, in the vicinity of the damage waterplane, contain no substantial quantity of accommodation or machinery and spaces which are not generally occupied by any substantial quantity of cargo or stores.

(d) Assumed extent of damage shall be as follows:

(i) longitudinal extent: 3.05 metres (10 feet) plus 3 per cent of the length of the ship, or 10.67 metres (35 feet) whichever is the less. Where the required factor of subdivision is .33 or less the assumed longitudinal extent of damage shall be increased as necessary so as to include any two consecutive main transverse watertight bulkheads;

(ii) transverse extent (measured inboard from the ship’s side, at right angles to the centre line at the level of the deepest subdivision load line): a distance of one‑fifth of the breadth of the ship, as defined in Regulation 2 of this Chapter; and

(iii) vertical extent: from the base line upwards without limit.

(iv) If any damage of lesser extent than that indicated in sub‑paragraphs (i), (ii) and (iii) of this paragraph would result in a more severe condition regarding heel or loss of metacentric height, such damage shall be assumed in the calculations.

(e) Unsymmetrical flooding is to be kept to a minimum consistent with efficient arrangements. Where it is necessary to correct large angles of heel, the means adopted shall, where practicable, be self‑acting, but in any case where controls to cross‑flooding fittings are provided they shall be operable from above the bulkhead deck. These fittings together with their controls as well as the maximum heel before equalization shall be acceptable to the Administration. Where cross‑flooding fittings are required the time for equalization shall not exceed 15 minutes. Suitable information concerning the use of cross‑flooding fittings shall be supplied to the master of the ship.

(f) The final conditions of the ship after damage and, in the case of unsymmetrical flooding, after equalization measures have been taken shall be as follows:

(i) in the case of symmetrical flooding there shall be a positive residual metacentric height of at least 50 millimetres (2 inches) as calculated by the constant displacement method;

(ii) in the case of unsymmetrical flooding the total heel shall not exceed seven degrees, except that in special cases, the Administration may allow additional heel due to the unsymmetrical moment, but in no case shall the final heel exceed fifteen degrees;

(iii) in no case shall the margin line be submerged in the final stage of flooding. If it is considered that the margin line may become submerged during an intermediate stage of flooding, the Administration may require such investigations and arrangements as it considers necessary for the safety of the ship.

(g) The master of the ship shall be supplied with the data necessary to maintain sufficient intact stability under service conditions to enable the ship to withstand critical damage. In the case of ships requiring cross‑flooding the master of the ship shall be informed of the conditions of stability on which the calculations of heel are based and be warned that excessive heeling might result should the ship sustain damage when in a less favourable condition.

(h) (i) No relaxation from the requirements for damage stability may be considered by the Administration unless it is shown that the intact metacentric height in any service condition necessary to meet these requirements is excessive for the service intended.

(ii) Relaxations from the requirements for damage stability shall be permitted only in exceptional cases and subject to the condition that the Administration is to be satisfied that the proportions, arrangements and other characteristics of the ship are the most favourable to stability after damage which can practically and reasonably be adopted in the particular circumstances.

Regulation 8

Ballasting

When ballasting with water is necessary, the water ballast should not in general be carried in tanks intended for oil fuel. In ships in which it is not practicable to avoid putting water in oil fuel tanks, oily‑water separator equipment to the satisfaction of the Administration shall be fitted, or other alternative means acceptable to the Administration shall be provided for disposing of the oily‑water ballast.

Regulation 9

Peak and Machinery Space Bulkheads, Shaft Tunnels, etc.

(a) (i) A ship shall have a forepeak or collision bulkhead, which shall be watertight up to the bulkhead deck. This bulkhead shall be fitted not less than 5 per cent of the length of the ship, and not more than 3.05 metres (10 feet) plus 5 per cent of the length of the ship from the forward perpendicular.

(ii) If the ship has a long forward superstructure, the forepeak bulkhead shall be extended weathertight to the deck next above the bulkhead deck. The extension need not be fitted directly over the bulkhead below, provided it is at least 5 per cent of the length of the ship from the forward perpendicular, and the part of the bulkhead deck which forms the step is made effectively weathertight.

(b) An afterpeak bulkhead, and bulkheads dividing the machinery space, as defined in Regulation 2 of this Chapter, from the cargo and passenger spaces forward and aft, shall also be fitted and made watertight up to the bulkhead deck. The afterpeak bulkhead may, however, be stepped below the bulkhead deck, provided the degree of safety of the ship as regards subdivision is not thereby diminished.

(c) In all cases stern tubes shall be enclosed in watertight spaces of moderate volume. The stern gland shall be situated in a watertight shaft tunnel or other watertight space separate from the stern tube compartment and of such volume that, if flooded by leakage through the stern gland, the margin line will not be submerged.

Regulation 10

Double Bottoms

(a) A double bottom shall be fitted extending from the forepeak bulkhead to the afterpeak bulkhead as far as this is practicable and compatible with the design and proper working of the ship.

(i) In ships 50 metres (165 feet) and under 61 metres (200 feet) in length a double bottom shall be fitted at least from the machinery space to the forepeak bulkhead, or as near thereto as practicable.

(ii) In ships 61 metres (200 feet) and under 76 metres (249 feet) in length a double bottom shall be fitted at least outside the machinery space, and shall extend to the fore and after peak bulkheads, or as near thereto as practicable.

(iii) In ships 76 metres (249 feet) in length and upwards, a double bottom shall be fitted amidships, and shall extend to the fore and after peak bulkheads, or as near thereto as practicable.

(b) Where a double bottom is required to be fitted its depth shall be to the satisfaction of the Administration and the inner bottom shall be continued out to the ship’s sides in such a manner as to protect the bottom to the turn of the bilge. Such protection will be deemed satisfactory if the line of intersection of the outer edge of the margin plate with the bilge plating is not lower at any part than a horizontal plane passing through the point of intersection with the frame line amidships of a transverse diagonal line inclined at 25 degrees to the base line and cutting it at a point one‑half the ship’s moulded breadth from the middle line.

(c) Small wells constructed in the double bottom in connexion with drainage arrangements of holds, etc., shall not extend downwards more than necessary. The depth of the well shall in no case be more than the depth less 457 millimetres (18 inches) of the double bottom at the centreline, nor shall the well extend below the horizontal plane referred to in paragraph (b) of this Regulation. A well extending to the outer bottom is, however, permitted at the after end of the shaft tunnel of screw‑ships. Other wells (e.g., for lubricating oil under main engines) may be permitted by the Administration if satisfied that the arrangements give protection equivalent to that afforded by a double bottom complying with this Regulation.

(d) A double bottom need not be fitted in way of watertight compartments of moderate size used exclusively for the carriage of liquids, provided the safety of the ship, in the event of bottom or side damage, is not, in the opinion of the Administration, thereby impaired.

(e) In the case of ships to which the provisions of paragraph (d) of Regulation 1 of this Chapter apply and which are engaged on regular service within the limits of a short international voyage as defined in Regulation 2 of Chapter III, the Administration may permit a double bottom to be dispensed with in any part of the ship which is subdivided by a factor not exceeding .50, if satisfied that the fitting of a double bottom in that part would not be compatible with the design and proper working of the ship.

Regulation 11

Assigning, Marking and Recording of Subdivision Load Lines

(a) In order that the required degree of subdivision shall be maintained, a load line corresponding to the approved subdivision draught shall be assigned and marked on the ship’s sides. A ship having spaces which are specially adapted for the accommodation of passengers and the carriage of cargo alternatively may, if the owners desire, have one or more additional load lines assigned and marked to correspond with the subdivision draughts which the Administration may approve for the alternative service conditions.

(b) The subdivision load lines assigned and marked shall be recorded in the Passenger Ship Safety Certificate, and shall be distinguished by the notation C.1 for the principal passenger condition, and C.2, C.3, etc., for the alternative conditions.

(c) The freeboard corresponding to each of these load lines shall be measured at the same position and from the same deck line as the freeboards determined in accordance with the International Convention respecting Load Lines in force.

(d) The freeboard corresponding to each approved subdivision load line and the conditions of service for which it is approved, shall be clearly indicated on the Passenger Ship Safety Certificate.

(e) In no case shall any subdivision load line mark be placed above the deepest load line in salt water as determined by the strength of the ship and/or the International Convention respecting Load Lines in force.

(f) Whatever may be the position of the subdivision load line marks, a ship shall in no case be loaded so as to submerge the load line mark appropriate to the season and locality as determined in accordance with the International Convention respecting Load Lines in force.

(g) A ship shall in no case be so loaded that when she is in salt water the subdivision load line mark appropriate to the particular voyage and condition of service is submerged.

Regulation 12

Construction and Initial Testing of Watertight Bulkheads, etc.

(a) Each watertight subdivision bulkhead, whether transverse or longitudinal, shall be constructed in such a manner that it shall be capable of supporting, with a proper margin of resistance, the pressure due to the maximum head of water which it might have to sustain in the event of damage to the ship but at least the pressure due to a head of water up to the margin line. The construction of these bulkheads shall be to the satisfaction of the Administration.

(b) (i) Steps and recesses in bulkheads shall be watertight and as strong as the bulkhead at the place where each occurs.

(ii) Where frames or beams pass through a watertight deck or bulkhead, such deck or bulkhead shall be made structurally watertight without the use of wood or cement.

(c) Testing main compartments by filling them with water is not compulsory. When testing by filling with water is not carried out, a hose test is compulsory; this test shall be carried out in the most advanced stage of the fitting out of the ship. In any case, a thorough inspection of the watertight bulkheads shall be carried out.

(d) The forepeak, double bottoms (including duct keels) and inner skins shall be tested with water to a head corresponding to the requirements of paragraph (a) of this Regulation.

(e) Tanks which are intended to hold liquids, and which form part of the subdivision of the ship, shall be tested for tightness with water to a head up to the deepest subdivision load line or to a head corresponding to two‑thirds of the depth from the top of keel to the margin line in way of the tanks, whichever is the greater; provided that in no case shall the test head be less than 0.92 metres (3 feet) above the top of the tank.

(f) The tests referred to in paragraphs (d) and (e) of this Regulation are for the purpose of ensuring that the subdivision structural arrangements are watertight and are not to be regarded as a test of the fitness of any compartment for the storage of oil fuel or for other special purposes for which a test of a superior character may be required depending on the height to which the liquid has access in the tank or its connexions.

Regulation 13

Openings in Watertight Bulkheads

(a) The number of openings in watertight bulkheads shall be reduced to the minimum compatible with the design and proper working of the ship; satisfactory means shall be provided for closing these openings.

(b) (i) Where pipes, scuppers, electric cables, etc. are carried through watertight subdivision bulkheads, arrangements shall be made to ensure the integrity of the watertightness of the bulkheads.